Ultrasonic Vibration Screen Generator is a high-frequency signal device designed to enhance the performance of fine mesh sieving. It works by converting standard electrical signals into 36–40kHz high-frequency mechanical vibrations, which are transmitted to the screen surface via an ultrasonic transducer. This vibration prevents mesh clogging, improves throughput, and allows finer materials—down to 20 microns or even smaller—to pass through efficiently. The system is widely used in industries like pharmaceuticals, chemicals, food, and metallurgy, where precise powder separation is essential. It is compatible with various vibrating screen types and can be retrofitted to existing machines. The Ultrasonic Generator 800 model typically supports mesh sizes from 20 to 500 mesh, offering stable output, energy efficiency, and easy integration. It features automatic frequency tracking, low heat generation, and a user-friendly interface. Ideal for difficult-to-screen powders such as graphite, tungsten carbide, zinc oxide, and lithium battery materials.

The ultrasonic vibrating screen transducer is an indispensable accessory of the ultrasonic vibrating screen and is the core device of the ultrasonic vibrating screen. The ultrasonic transducer on the ultrasonic vibrating screen can make the material have an additional high-frequency and low-amplitude force on the screen surface, the contact time between the material and the screen surface becomes shorter, and the vibration frequency becomes larger, so the blocking of the material can be greatly reduced. The screening accuracy can be increased by 1-70% compared with the ordinary vibrating screen, and the output can be increased by 0.5-10 times.

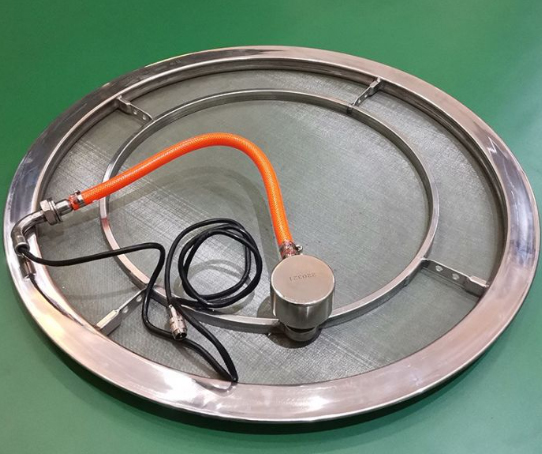

To improve the screening efficiency and accuracy. According to different installation methods, the transducer is divided into two types: built-in and external. The built-in transducer is installed inside the screen frame or screen, with a compact structure, high energy transfer efficiency, and good sealing performance. It is particularly suitable for industries such as medicine and food that have high requirements for hygiene and airtightness, but the equipment needs to be disassembled for maintenance, and the operation is relatively complicated. The external transducer is installed on the outside of the screen or equipment, which is convenient to install and replace, simple to maintain, and has good heat dissipation. It is suitable for continuous work and general powder industries, such as chemical industry and metallurgy. Its structure is relatively open, and its sealing is slightly inferior to that of the built-in type. Both structures have their own advantages. Users should choose the appropriate transducer form according to specific working conditions, material characteristics and production environment to ensure screening efficiency and stable operation of the equipment.

The main function of ultrasonic vibrating screen transducer is to convert the high-frequency electrical signal (usually 36kHz~40kHz) output by the ultrasonic generator into high-frequency mechanical vibration, and transmit it to the surface of the screen to form ultrasonic vibration. This high-frequency micro-vibration can effectively prevent the screen from clogging, improve the screening accuracy and efficiency, and is especially suitable for the screening of micro-powders, ultra-fine powders, and difficult-to-screen materials, such as pharmaceutical powders, metal powders, chemical raw materials, etc.

Address:China,Yanjin county forest park gate to the west 1000 meters north road.