Vaccum Suction Pump For Paddy is a conveyor system designed for transporting high-moisture rice. It solves the problems of slow and difficult transport in traditional rice handling, enabling seamless transport of freshly harvested, high-moisture rice from field transport vehicles to the dryer for dehydration. The flexible hose can be bent 360° and can be equipped with omnidirectional casters to flexibly connect to transport vehicles of different heights and dryer inlets. It supports horizontal and inclined multi-angle conveying, with a conveying length of up to 30 meters and a processing capacity of 3-10 tons per hour, adaptable to different scales of rice processing needs.

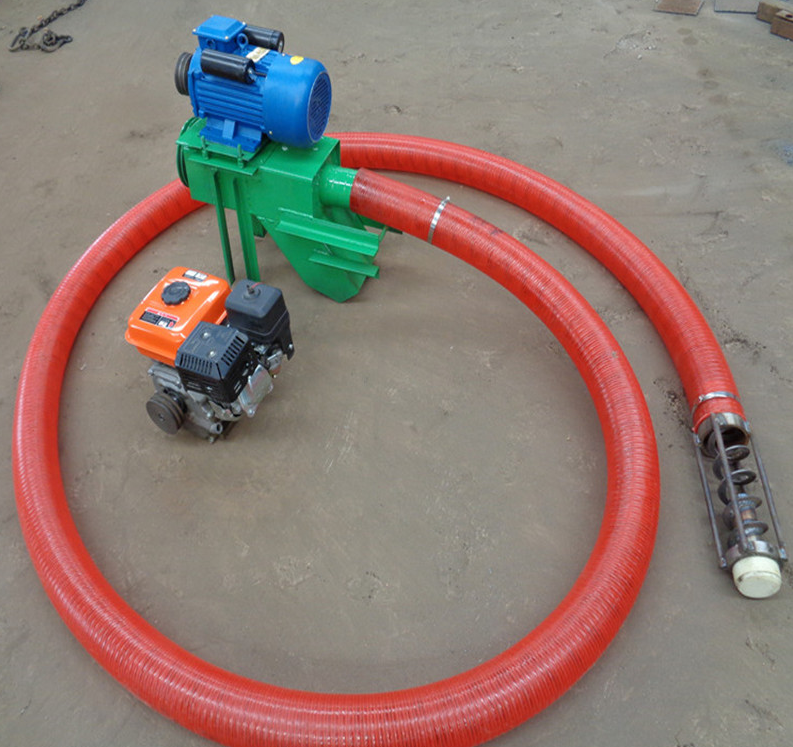

Based on customer needs, we offer Vaccum Suction Pumps for Paddy in both flexible hose and stainless steel versions. We can select the appropriate conveyor based on the specific rice transport scenario.

Flexible Hose Vaccum Suction Pump for Paddy: The flexible hose is made of wear-resistant, durable, and anti-aging rubber, suitable for rough conditions such as mobile field harvesting and temporary transfers. It offers high cost-effectiveness and is suitable for small and medium-sized rice planting cooperatives and mobile grain traders.

Stainless Steel Vaccum Suction Pump for Paddy: Core contact components such as the spiral blades and feed inlet are made of 304 stainless steel, which is corrosion-resistant and easy to clean. It can handle the high humidity of rice transport, preventing rust and contamination of the rice. This is primarily handheld and used in small-scale applications such as rice bagging and loading.

The Vaccum Suction Pump for Paddy utilizes its unique structure to easily transport rice to designated locations. The flexible hose adapts to various scenarios, and the stainless steel blades protect the grain from breakage, quickly solving the pain points of slow rice transport and labor-intensive processes.

Multi-purpose: Customizable lengths from 2-30 meters are available. Supports two-phase or three-phase power, suitable for family farms, fields, factories, and other scenarios.

Damage-free transport: Utilizing a highly elastic, wear-resistant hose paired with stainless steel spiral blades with polished edges, the pump eliminates hard friction during transport, effectively preventing rice grain breakage and hulling.

Easy to Use: The flexible hose allows for free bending, supporting horizontal, inclined, and vertical multi-angle conveying, enabling it to flexibly navigate narrow spaces in fields and grain depots, and easily connect to different height inlets on transport vehicles and dryers.

Corrosion Resistant and Easy to Maintain: Core contact components are made of stainless steel, resistant to moisture and corrosion, meeting the long-term conveying needs of rice with high moisture content; the hose is easy to disassemble and daily maintenance is simple.

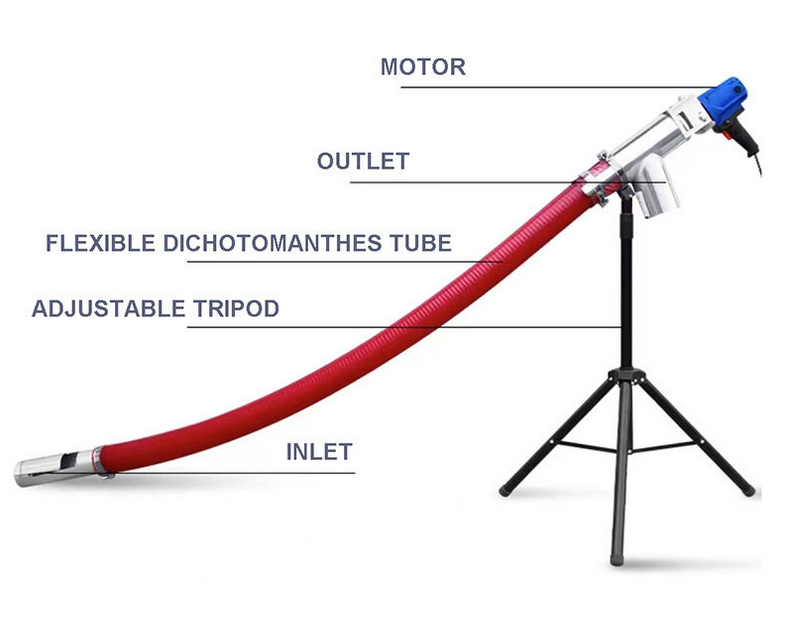

The Vaccum Suction Pump For Paddy easily sucks up rice with high moisture content, eliminating the problem of rice transportation. Its overall structure is simple and compact with clear division of labor; the proper use of each component ensures the normal operation of the entire conveying system.

Vacuum Pump: Generates negative pressure to adsorb the rice, conveying it from the ground or field to the discharge port using spiral blades.

Flexible Conveying Structure: Consists of a highly elastic, wear-resistant hose, food-grade stainless steel spiral blades, and a drive motor.

Feeding and Discharging: The feed inlet is equipped with an anti-clogging auger to ensure smooth entry of rice with high moisture content; the discharge outlet is fitted with a buffer baffle to reduce the impact of falling rice grains and prevent splashing loss. It can also be connected to a dryer. The casters have a braking function, and the outriggers allow for flexible height adjustment to meet the docking needs of different transport vehicles and feed inlets.

When the Vaccum Suction Pump For Paddy is working, a vacuum pump first creates a negative pressure environment inside the hose. The pressure difference draws rice and other materials from the stockpile or field into the hose. After the material enters the hose, the embedded shaftless helical blades rotate under the drive of a motor. The helical propulsion force continuously conveys the material forward along the hose. The shaftless design prevents long-fiber materials like rice from tangling. At the end of the conveying process, the material is discharged from the discharge outlet under gravity or the reverse rotation of the helical blades.

Flexible Hose Vaccum Suction Pump for Paddy

| Model No. |

Length (Meters) |

Pipe diameter |

Loading Capacity (t/h) |

Motor phase-power (kw) |

Installation | Structure | Conveying height |

| RLS100 | 4 meter | 100mm | 5—8 | Single phase-3kw | Vehicle mounted | Steel screw blade inside | Depends on case |

| 5 meter | 100mm | 5—8 | Single phase-3kw | Vehicle mounted | Steel screw blade inside | ||

| 6 meter | 100mm | 5—8 | Single phase-3kw | Vehicle mounted | Steel screw blade inside | ||

| 8 meter | 100mm | 5—8 | Single phase-3kw | Vehicle mounted | Steel screw blade inside | ||

| (Customized) | |||||||

| RLS120 | 4 meter | 120mm | 10—15 | Three phase-4KW | Vehicle mounted | Steel screw blade inside | Depends on case |

| 5 meter | 120mm | 10—15 | Three phase-4KW | Vehicle mounted | Steel screw blade inside | ||

| 6 meter | 120mm | 10—15 | Three phase-4KW | Vehicle mounted | Steel screw blade inside | ||

| 8 meter | 120mm | 10—15 | Three phase-4KW | Vehicle mounted | Steel screw blade inside | ||

| (Customized) | |||||||

| RLS-160 | 4meter | 160mm | 10—15 | Three phase-5KW | Vehicle mounted | Steel screw blade inside | Depends on case |

| 5meter | |||||||

| 6meter | |||||||

| 8meter | |||||||

| (Customized) | |||||||

Stainless Steel Vaccum Suction Pump for Paddy

| Model | Length(m) | Diameter(mm) | Rated voltage(v) | Matching power(kw) | weight(kg) |

| stainless steel | 1.5 | 100 | 220V | 2KW | 10-20 |

| 2 | 100 | 220V | 2KW | 10-20 | |

| 2.5 | 100 | 220V | 2KW | 10-20 | |

| 3 | 100 | 220V | 2KW | 10-20 | |

| 3.5 | 100 | 220V | 2KW | 10-20 | |

| 4 | 100 | 220V | 2KW | 10-20 |

The Vaccum Suction Pump For Paddy, with its core advantages of flexible mobility and strong grain protection, is widely adaptable to the entire process of rice transportation from harvesting to processing.

Field Mobile Grain Collection: Equipped with omnidirectional casters, it can directly connect to the unloading ports of combine harvesters or agricultural vehicles in the field, quickly completing the dehydration and loading of high-moisture rice, improving the operational efficiency of farmers and mobile grain collection.

Grain Purchasing Stations: Addressing the characteristics of centralized grain collection, high rice moisture content, and slow collection speed at purchasing stations, the pump can adjust the conveyor speed to process rice with different moisture contents in batches, directly transporting it to storage silos or dryers.

Rice Processing Plants: As a conveyor before the dryers in processing plants, it can quickly transfer high-moisture rice entering the plant to the drying line, reducing drying time and improving processing efficiency.

Rice Planting Bases: Adapted to large-scale, mechanized operations, multiple machines can work together, connecting with large harvesters and storage systems to achieve continuous rice harvesting and transportation.

Choosing the right Vaccum Suction Pump for Paddy requires considering your operational needs, material characteristics, and site conditions to determine which conveyor is suitable. Before purchasing, you should first determine your specific requirements and then select the appropriate conveyor model.

Consider the processing capacity and conveying distance: Small farmers and mobile grain collection points should choose small models with a capacity of 3-8 tons per hour and a hose length of 4-8 meters for flexible movement and suitability for scattered grain collection; large-scale planting bases and processing plants should choose models with a capacity of 10-20 tons per hour and a hose length of 8-15 meters.

Consider the material selection based on the working conditions: For rough field conditions, choose wear-resistant rubber hoses for anti-aging and impact resistance; for scenarios with high cleanliness requirements, such as rice processing plants, choose food-grade stainless steel to avoid contaminating the rice.

Match site requirements: For fields and temporary grain collection points, choose models with omnidirectional casters and height-adjustable outriggers for flexible connection to agricultural vehicles and dryers.

The Vaccum Suction Pump for Paddy manufactured by DaHan Machinery starts at $80, with pricing tailored to the operational needs of different users, offering significant cost-effectiveness. Price differences mainly stem from hose material, conveyor length, throughput, and customized configurations. Personalized requirements such as frequency converter control and mobile frames can be precisely quoted. As a factory direct seller, eliminating intermediaries, we offer readily available standard models, free selection consultation, and non-standard customization services. We can tailor a suitable conveyor to your production needs and site conditions, providing cost-effective rice conveying solutions for users of all sizes.

Dahan Machinery is a major manufacturer of conveyors, integrating independent R&D, production, sales, and after-sales support. The Vaccum Suction Pump For Paddy supports customized requirements for hoses, stainless steel materials, and conveying parameters, adapting to diverse scenarios such as field harvesting, grain transfer at purchasing stations, and pre-processing in processing plants. Adopting a direct-sales model, eliminating intermediaries, we provide high-performance, cost-effective products. We can create conveying solutions and 3D renderings based on drawings and production environments, supporting global sales to meet the needs of customers in different countries.

The Vaccum Suction Pump For Paddy solves the pain points of rice transportation, such as dusting, breakage, and high energy consumption, by effectively conveying rice with high moisture content. Its flexible mobility and adaptable materials cater to diverse scenarios, meeting the needs of small-scale farmers and large-scale grain enterprises, making it the preferred conveyor for improving rice processing efficiency and reducing costs.

Address:China,Yanjin county forest park gate to the west 1000 meters north road.