Vibro Separation Machine for Potassium Nitrate is an advanced vibrating separation equipment designed for efficient screening and grading of potassium nitrate materials. The equipment adopts a multi-layer vibrating screen structure, combined with a high-frequency and low-amplitude vibration method, which can accurately grade potassium nitrate particles of different particle sizes in a short time, with a screening efficiency of more than 99%, effectively improving product purity, reducing dust content, and ensuring material quality.

The body of the Vibro Separation Machine is made of stainless steel, with excellent corrosion resistance and sealing, and is suitable for industries such as chemical, pharmaceutical, and food that have high requirements for hygiene and purity. The equipment has a compact design and a small footprint, suitable for various production line layouts.

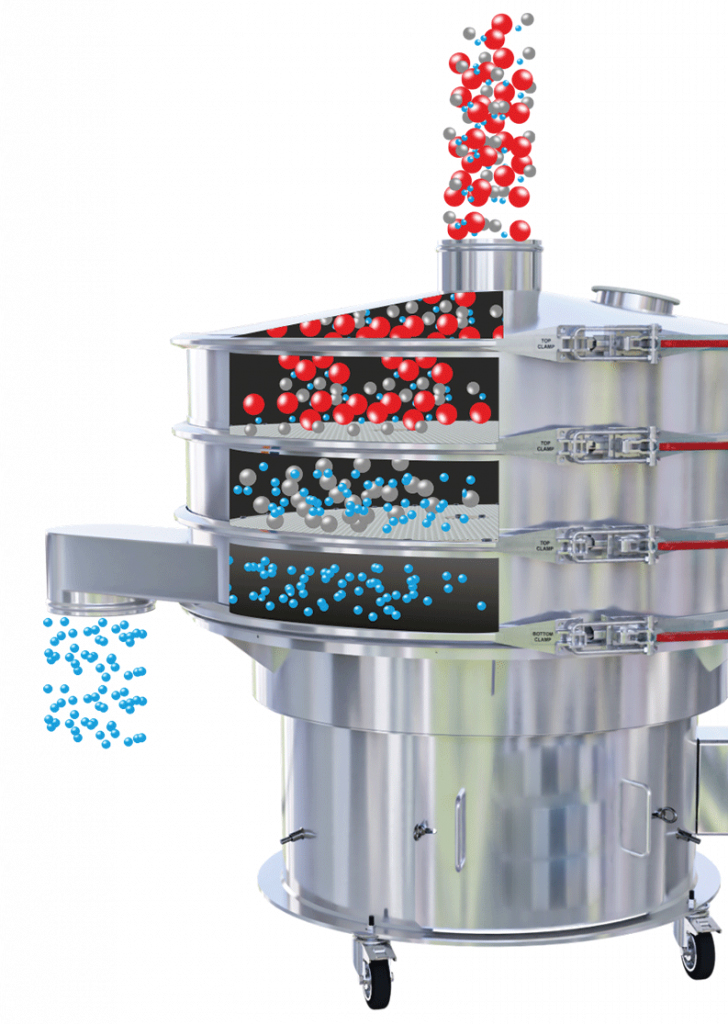

The machine utilizes high-frequency vibration (800-3000 RPM) generated by an unbalanced motor or electromagnetic exciter, creating a gyratory or linear motion to separate particles. Key stages:

Stratification: KNO₃ particles stratify by size.

Screening: Smaller particles pass through mesh apertures.

Discharge: Separated fractions exit via designated chutes.

Vibro Separation Machine for Potassium Nitrate offers superior grading efficiency with 99%+ purity, handling 0.5-10 TPH of KNO₃ crystals/powder. Its 304 stainless steel mesh (50-800µm) ensures precise size separation, while adjustable vibration frequency (800-3000 RPM) prevents clogging. Key advantages: explosion-proof options (ATEX) for combustible dust, ultrasonic deblinding for sticky powders, and low-noise (<75dB) operation. Ideal for fertilizer, pyrotechnics, and food-grade KNO₃ processing, reducing waste by 20% versus manual screening. (Options: CIP cleaning, multi-layer decks)

High Purity Output: Achieves ≥99% separation efficiency.

Gentle Handling: Minimizes crystal breakage.

Scalable Capacity: Processes 0.5–10 TPH depending on mesh size.

Low Maintenance: No lubricants, easy screen

Explosion-Proof: ATEX-certified models for combustible dust.

When screening hygroscopic and agglomerated materials such as potassium nitrate, the equipment can be equipped with an ultrasonic system to effectively prevent screen clogging and ensure a smooth and continuous screening process. 。

Address:China,Yanjin county forest park gate to the west 1000 meters north road.