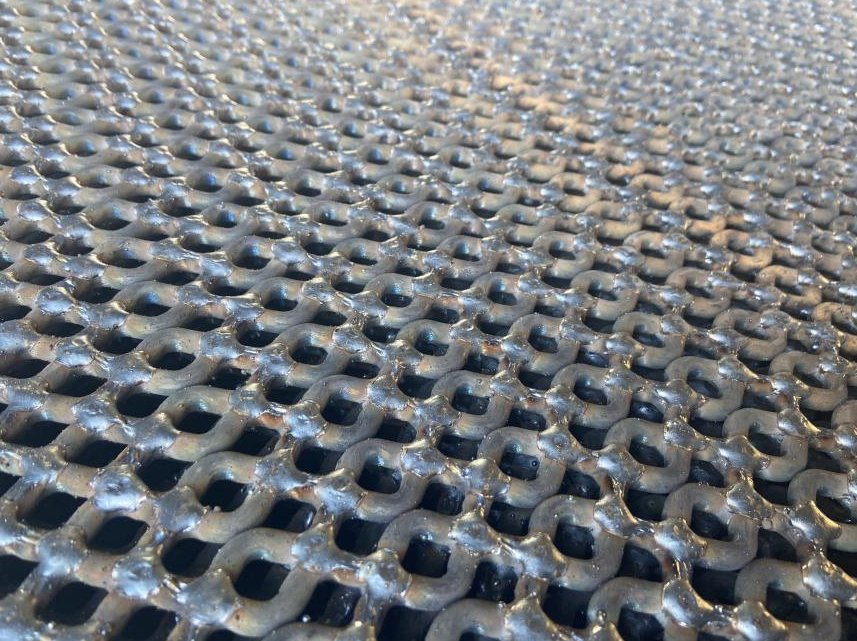

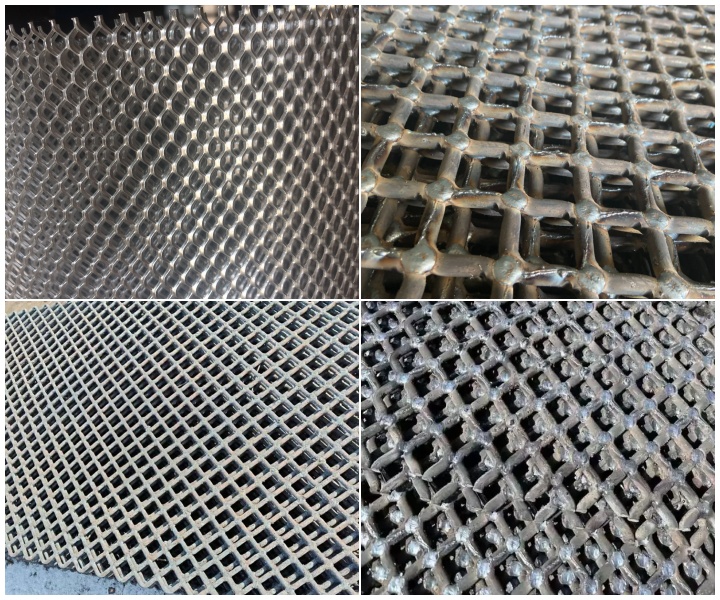

Welded slotted screen are rigid screens made from high-strength metal sheets through cutting, bending, and welding. Their core structure consists of trough-shaped screen bars and supporting ribs. The screen bars have a trapezoidal or rectangular cross-section and are firmly connected to the transverse supporting ribs through precision welding, forming a highly rigid trough-shaped screening surface suitable for grading materials of different particle sizes.

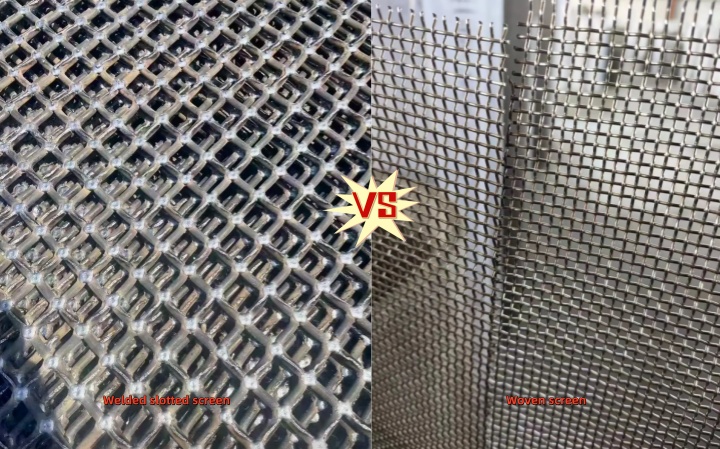

Compared to traditional woven and perforated screens, welded slotted screens offer the key advantages of high rigidity, impact resistance, and wear resistance. Their integrated welded structure avoids the breakage defects at the warp and weft joints of woven screens and overcomes the insufficient strength caused by the dense holes in perforated screens. They can easily withstand the high-frequency impact and friction of large-particle, high-hardness materials, and their service life in heavy-duty screening equipment can be 3-5 times that of traditional screens.

The design and manufacturing of welded slotted screens are perfectly suited to the needs of high-intensity screening scenarios, exhibiting significant advantages in strength, screening efficiency, and wear resistance, making them the preferred core component in heavy-duty screening.

High Customization: Welded slotted screens can be fully customized to meet the needs of different screening equipment types, material characteristics, and production capacity requirements. Screen size, mesh specifications, bar material, and support rib spacing can all be designed to meet specific needs.

Strong Impact Resistance: The bar material is made of high-strength metals such as manganese steel and stainless steel, capable of withstanding the impact of ores, sand, and gravel weighing tens of kilograms per particle. It is not easily deformed or broken, and can operate stably for extended periods under high-flow, high-load screening conditions.

Excellent Wear Resistance: For screening high-abrasion materials, welded slotted screens can be made of high-manganese steel or undergo surface wear-resistant treatment. High-manganese steel has the characteristic of becoming harder with wear; under material impact and friction, a hardened layer forms on the surface, significantly improving wear resistance.

High screening efficiency: The trough-shaped screen bars of the welded slotted screen create a certain inclination angle on the screening surface. As the material slides on the screen surface, fine particles can quickly pass through the slotted screen openings, while larger particles are smoothly discharged along the screen surface, effectively preventing material accumulation.

With its unique welded structure design, excellent load-bearing capacity, and ultra-long service life, the welded slotted screen is the ideal choice for screening high-impact, high-abrasion materials. In contrast, traditional woven mesh, made of warp and weft yarns, has low structural strength and is prone to deformation and breakage under impact from high-hardness materials, and its screen openings are easily clogged. The welded slotted screen uses an integrated welding process, resulting in high rigidity, impact resistance, and wear resistance 3-5 times that of woven mesh. Its open area ratio is controllable and it is less prone to clogging, making it more suitable for heavy-duty screening conditions in mining and sand and gravel industries.

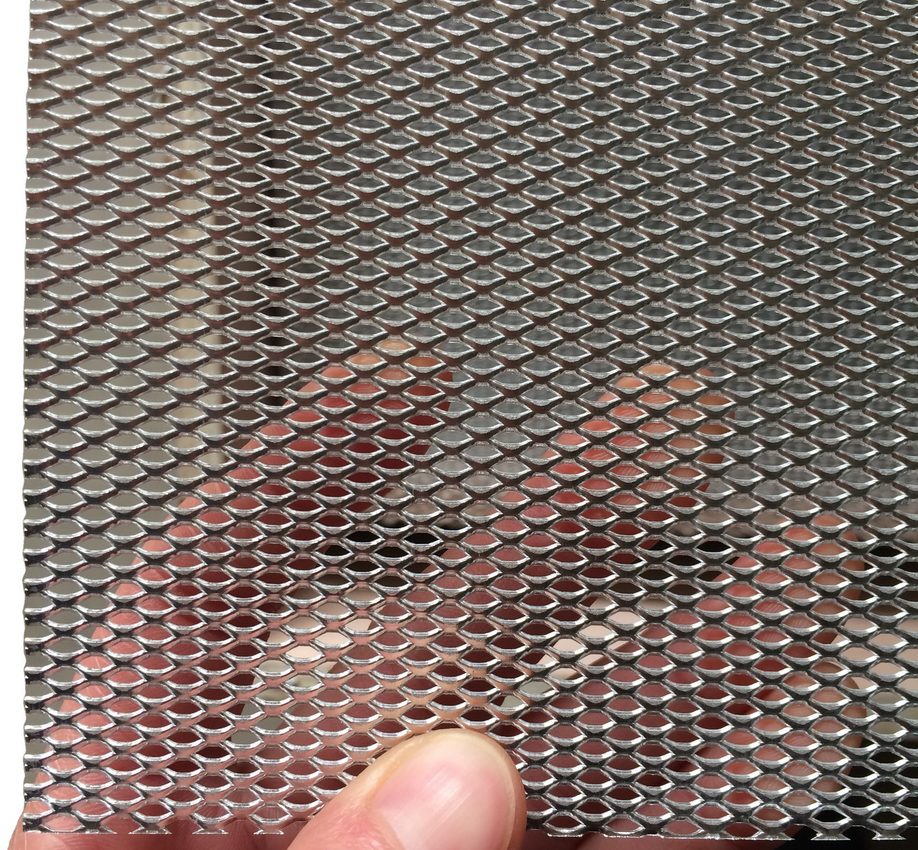

The mesh size of the welded slotted screen can be flexibly customized according to screening needs, typically achieving fine screening from 20-400 mesh, adapting to various grading requirements from coarse particles to fine powders. Its trough-shaped screen bar design creates a natural inclined angle on the screening surface, allowing fine particles to quickly pass through the mesh while larger particles are smoothly discharged, preventing accumulation and clogging at the source. The slotted screen openings are more adaptable to flaky and strip-shaped materials, balancing high-flow screening efficiency with precise grading.

Welded slotted screens, with their unique welded structure design, excellent load-bearing capacity, and ultra-long service life, are commonly made from five main materials: high manganese steel, 304 stainless steel, 304L stainless steel, 316 stainless steel, and 316L stainless steel.

High manganese steel: The preferred material for high-strength screening applications, capable of withstanding high-frequency impacts from ores and aggregates in mines, resistant to deformation and breakage, suitable for coarse screening and heavy-duty screening conditions.

304 stainless steel: Offers good resistance to atmospheric corrosion and weak acids and alkalis. Lightweight and easy to clean, it is suitable for screening building materials, coal, food raw materials, and other non-corrosive environments.

304L Stainless Steel: A low-carbon version of 304, with a carbon content ≤0.03%. It avoids intergranular corrosion due to carbon precipitation during welding, resulting in superior weldability. Suitable for large-scale screen equipment requiring welding assembly, it can operate stably for extended periods in humid and mildly corrosive environments.

316 Stainless Steel: Due to the addition of molybdenum, its corrosion resistance is significantly improved. It can withstand the erosion of strong corrosive media such as seawater and chemical solutions, making it suitable for screening corrosive materials such as chemical raw materials, marine engineering materials, and electroplating waste.

316L Stainless Steel: A low-carbon improved version of 316, with an even lower carbon content and stronger resistance to intergranular corrosion. It also possesses good toughness and weldability, making it suitable for screening applications with high corrosion and high hygiene standards.

With its unique welded structure design, excellent load-bearing capacity, and ultra-long service life, the welded slotted screen is widely used in various heavy-duty vibrating screen equipment, providing reliable support for large-scale screening operations. It is suitable for a wide range of materials across multiple industries, including screening large-particle-size, high-hardness ores such as iron ore, granite, and limestone in the mining industry; aggregates such as river sand and manufactured sand in the sand and gravel industry; raw coal and refined coal in the coal industry, achieving grading, desliming, and dewatering operations; and meeting the screening needs of materials such as cement clinker and fertilizer granules in the chemical and building materials industries.

When selecting a welded slotted screen, the first priority is to choose a suitable material based on the material characteristics. High-manganese steel is preferred for high-hardness and high-abrasion materials; 304/316L stainless steel is suitable for corrosive materials. Secondly, determine the screen aperture size and opening ratio based on the screening requirements. Use large-aperture, low-opening-ratio screens for coarse screening, and small-aperture, high-opening-ratio screens for fine screening. Finally, determine the screen size and installation method based on the equipment model to ensure perfect compatibility.

DaHan Vibration Machinery possesses mature welding technology and a material selection system. Our welded slotted screens cover a full range of materials including high-manganese steel, 304/304L, and 316/316L. We can customize screens from 20-400 mesh, adaptable to various processes such as plain weave, double-strand weave, and Dutch weave. With its high rigidity, impact resistance, and wear- and clogging resistance, our products are widely used in mining, sand and gravel, coal, and chemical industries. We support customized non-standard sizes and installation methods, providing a one-stop service from selection and production to after-sales support. We can tailor suitable screens to your specific needs and equipment.

Our welded slotted screen, with its unique welded structure design, excellent load-bearing capacity, and ultra-long service life, is an ideal choice for screening high-impact and high-abrasion materials. It is widely used in various heavy-duty vibrating screens, providing reliable support for large-scale screening operations.

Address:China,Yanjin county forest park gate to the west 1000 meters north road.