Use linear vibration to convey and separate various materials

![]()

![]()

Price:$850.00-$5,000.00/Set

Consult now and enjoy a 10% discount

Layer: 1-6 layers

Mesh Size: 2-400mesh

Particle Size: 0.074-10mm

Vibration Direction Angle: 45-60°

Screen Inclination: 0-7°

Dual Amplitude: 3-4.5

Application: It can efficiently screen dry powder or granular materials and is widely used in chemical, food, pharmaceutical and other industries.

Commitment:

Linear vibratory sifter is suitable for dry powder or granular materials, as well as products with a high proportion of super large particles. 2-7 different levels can be achieved in one operation.

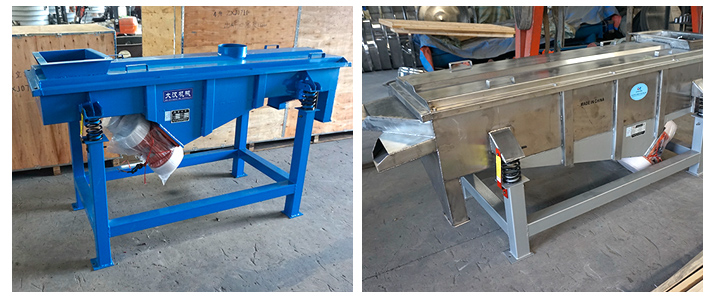

Linear vibratory sifter is divided into three different materials: carbon steel, stainless steel, and plastic. With the help of the weights installed on the upper and lower ends of the motor shaft, the exciting force of the motor is transmitted to the screen surface, and the screens of several specifications are produced through the multi-layer screen. The upper material and the lower material are discharged from their respective discharge ports. It has low energy consumption, high output, simple structure, easy maintenance, fully enclosed structure, no dust overflow, automatic discharge, and is more suitable for assembly line operations.

Driven by dual vibratory sifter, when two vibrating motors rotate synchronously and in opposite directions, the excitation force generated by the eccentric blocks cancels each other out in the direction parallel to the motor axis, and stacks in the direction perpendicular to the motor axis to form a resultant force. Therefore, the trajectory of the screen is a straight line. There is an inclination angle between the two motor shafts relative to the screen surface. Under the reasonable action of the exciting force and the material's self-gravity, the material entering the equipment is thrown up on the screen surface, jumping forward and making a linear parabolic movement, which is produced by the multi-layer screen. Several specifications of the oversize and undersize items are discharged from their respective discharge ports to achieve the purpose of screening and classification.

Wheat Bran Linear Vibratory Sifter

Linear Vibratory Sifter for Salt

Wide screening range

The linear vibratory sifter has a screening range from 20 to 400 meshes, and can handle materials with various fineness requirements, suitable for different screening needs in multiple industries. Its output can reach 20 tons per hour, meeting the needs of large-scale production.

Dual motor drive

The linear vibratory sifter is equipped with dual motors, which are installed perpendicular to each other to produce appropriate vibration flow. This arrangement enables the screen frame to move and vibrate in a straight line perpendicular to the motor, ensuring that oversized particles have a good forward propulsion effect.

Multi-level screening capability

The equipment can screen materials into 2, 3, 4, 5, 6 or 7 different levels, and flexibly respond to production processes with different fineness requirements. The equipment design allows the establishment of 1 to 6 layers of screens to meet a variety of screening needs.

Adjustable vibration motor

Equipped with an adjustable vibration motor, users can set different vibration frequencies and amplitudes according to actual needs. This design enables the equipment to adapt to different material characteristics and screening requirements.

| Model | Layer | Screening Area (mm) |

Mesh Size (mesh) |

Particle Size (mm) |

Capacity (t/h) |

Power (kw) |

Vibration Direction Angle (°) |

Screen Inclination (°) |

Dual Amplitude |

| DZSF-520 | 1-6 layers | 500*2000 | 2-400 | 0.074-10 | ≤3 | 0.37×2 | 45-60 | 0-7 | 3-4.5 |

| DZSF-525 | 500*2500 | ≤5 | 0.37×2 | ||||||

| DZSF-612 | 600*1200 | ≤8 | 0.37×2 | ||||||

| DZSF-1020 | 1000*2000 | ≤12 | 0.75×2 | ||||||

| DZSF-1025 | 1000*2500 | ≤16 | 0.75×2 | ||||||

| DZSF-1030 | 1000*3000 | ≤20 | 1.1×2 | ||||||

| DZSF-1224 | 1200*2400 | ≤23 | 1.5×2 | ||||||

| DZSF-1525 | 1500*2500 | ≤28 | 1.5×2 | ||||||

| DZSF-1530 | 1500*3000 | ≤32 | 2.2×2 |

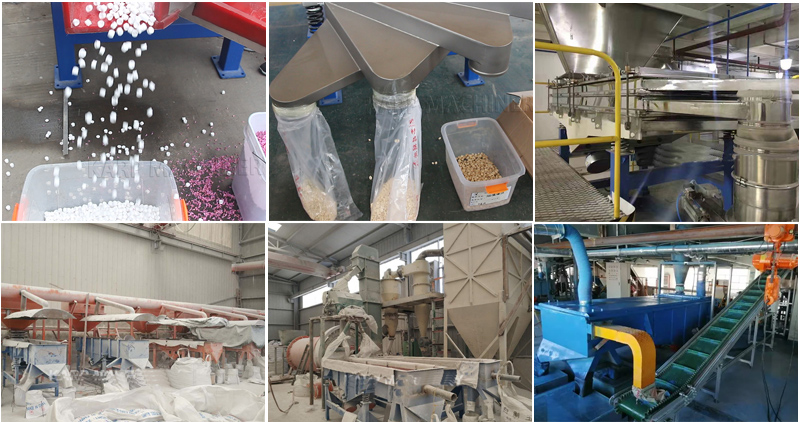

Linear vibratory sifters are widely used in the screening of dry powder or granular materials in the chemical, food, plastic, pharmaceutical, metallurgical, glass, building materials, grain, fertilizer, abrasive, ceramic and other industries. The following is a detailed introduction to its application in various industries:

Chemical industry: In the chemical industry, linear vibratory sifters are used to screen chemical raw materials and finished products, such as fertilizers, resins, pigments and various chemical powders.

Food industry: In the food industry, linear vibratory sifters are used to screen food raw materials such as flour, sugar, salt, starch, etc. It can effectively separate materials of different particle sizes.

Plastic industry: In the plastic industry, linear vibratory sifters are used to screen plastic particles and powders, such as polyethylene, polypropylene, etc.

Pharmaceutical industry: The pharmaceutical industry has extremely high requirements for screening accuracy, and linear vibratory sifters are used to screen pharmaceutical powders, granules and other medicines.

Metallurgical industry: In the metallurgical industry, linear vibratory sifters are used to screen materials such as ore, coal, and metal powder.

Building materials industry: In the building materials industry, linear vibratory sifters are used to screen building materials such as sand, gravel, cement, and lime.

Abrasive Industry: In the abrasive industry, linear vibratory sifters are used to screen various abrasives such as aluminum oxide, silicon carbide, etc.

Address:China,Yanjin county forest park gate to the west 1000 meters north road.