Z-type bucket elevator, with the shape of the letter Z or C, is a common lifting equipment that is mostly used in the food industry. It is usually used in food packaging lines to lift food from a low place to a combination scale or packaging in the plane.

1. The shell of the whole machine is designed to be closed, so there is less leakage of materials during the operation of the machine, and at the same time, it reduces the flying of dust, which meets the requirements of environmental protection.

2. The material is less damaged during the conveying process. The whole machine runs smoothly, and there is no extrusion or friction of the material during the operation, which reduces the damage of the material.

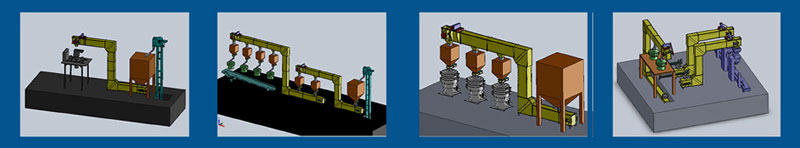

3. It can be used in Z-type, C-type and ZC-type, flexibly adapt to different factory layouts, and save production space to the greatest extent possible.

4. Multi-point cutting/feeding. Customers can customize multiple feed ports or feed ports according to actual lifting needs to meet the needs of multiple silos or multiple feed ports. One machine with multiple functions saves procurement costs.

5. It can be equipped with a vibrating feeder, and the flow-in type feeds at a constant speed to avoid material overflow that may be caused by manual feeding.

6. Save space. Due to its flexible composition, compact body and horizontal-vertical-horizontal conveying method, the Z-type bucket elevator greatly reduces the large area occupied by the equipment.

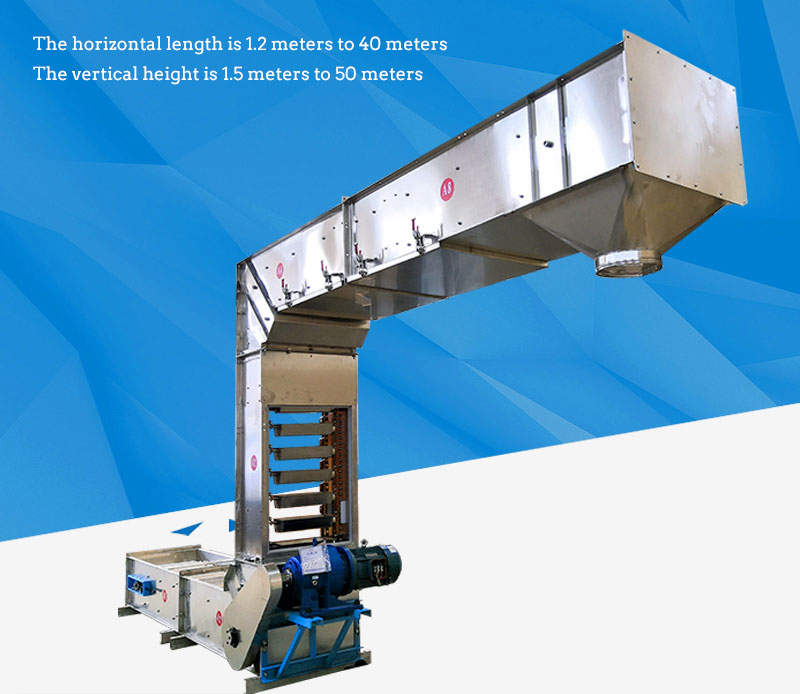

The Z-type bucket elevator can be designed according to the customer's site, the horizontal length is 1.2 meters to 40 meters, the vertical height is 1.5 meters to 50 meters, and the parallel connection method can be used for more than 30 meters, which is suitable for the process requirements of different industries.

The Z-type bucket elevator transports materials through the hopper hanging on the chain, and completes the work of single-point or multi-point unloading (multi-point unloading is not multi-point simultaneous unloading) through the unloading device at the unloading port.

Hopper material: food grade ABS hopper/stainless steel hopper/carbon steel hopper

Sprocket material: alloy steel sprocket/stainless steel sprocket

Control mode: manual/active (can be customized according to customer requirements)

Machine shell: closed/semi-closed

Address:China,Yanjin county forest park gate to the west 1000 meters north road.