belt bucket elevator TD160 is a vertical conveying device designed for granular and small block materials, using belt traction. Its 160mm wide bucket, hence the name Type 160 bucket elevator, is suitable for vertically conveying powdery, granular, and small block materials with low abrasiveness, such as grain, coal, cement, and crushed ore. It has a lifting height of up to 20m and a conveying capacity of 15-30m³/h, capable of quickly lifting materials such as wheat, corn, ore, and fertilizer. It offers buckets made of carbon steel, stainless steel, and PP materials to suit different workshop space requirements.

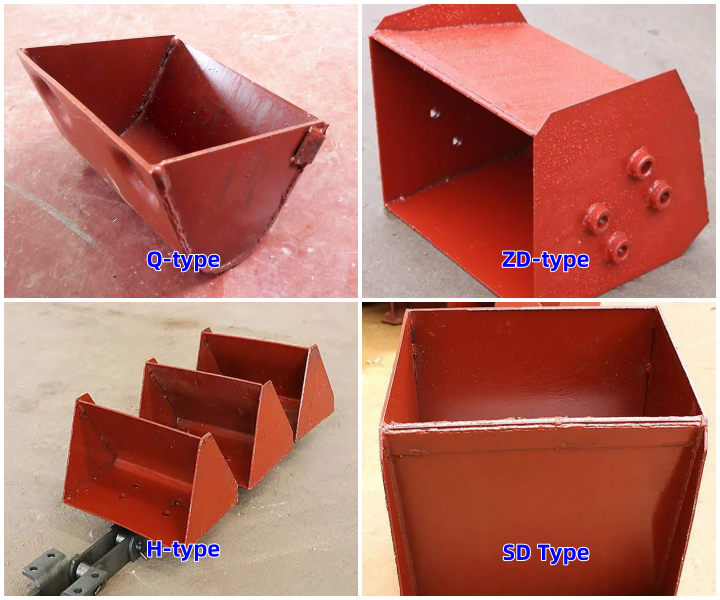

The belt bucket elevator TD160 is equipped with four types of buckets Q-type shallow buckets, H-type arc-bottom buckets, ZD-type medium-deep buckets, and SD-type deep buckets, which can be selected to suit different conveying scenarios.

Q-type (Shallow Bucket): A precise solution for moist, easily agglomerated materials. Approximately 50mm deep, with a small front wall inclination angle (45°) and a flat, non-curved bottom, reducing the risk of adhesion by minimizing material contact area. Suitable for moist materials such as wet sand, wet coal, and grains with high moisture content, as well as easily agglomerated chemical raw materials such as clay and fertilizers.

H-type (Arc Bottom Bucket): Optimized for the flow of powdery and lightweight materials. Features a semi-circular arc bottom, a large front wall inclination angle, and a vertical rear wall, utilizing gravity to promote natural material flow. High discharge efficiency and 15% energy reduction for powdery and lightweight materials with poor flowability.

ZD-type (Medium-Deep Bucket): Approximately 120mm deep, with a 50° front wall inclination angle and a slightly curved rear wall, balancing capacity and discharge performance. Suitable for medium-sized materials and mixtures. Single bucket capacity reaches 1.2L, with a conveying capacity ranging from 5.4 to 16 m³/h, offering optimal overall performance.

SD Type (Deep Bucket): An efficient engine for high-volume material drying, with a bucket depth of up to 190mm, a vertical or slightly tilted front wall, and a reinforced rear wall design. Each bucket has a capacity of 1.9L and is optimized for drying loose materials and high-volume production needs.

The belt bucket elevator TD160 features a compact structure and small footprint. Its 3-20 meter lifting height adapts to various scenarios. The high-strength conveyor belt and stamped buckets are durable and wear-resistant, with low operating noise. Customization of materials and functions is available.

Low Drive Power: Utilizing inflow feeding, induced discharge, and a dense arrangement of large-capacity buckets, there is virtually no material backflow or digging during material lifting, resulting in minimal wasted power.

Wide Lifting Range: It has few requirements regarding the type and characteristics of materials, capable of lifting not only general powdery and small granular materials but also highly abrasive materials.

Reliable Operation: Advanced design principles and processing methods ensure the reliability of the entire machine, with a mean time between failures (MTBF) exceeding 20,000 hours. High lifting height. The elevator operates smoothly, thus achieving a high lifting height.

Long service life: The elevator uses a flow-in feeding method, eliminating the need for bucket digging, minimizing material compression and collision. The machine is designed to minimize material spillage during feeding and unloading, reducing mechanical wear.

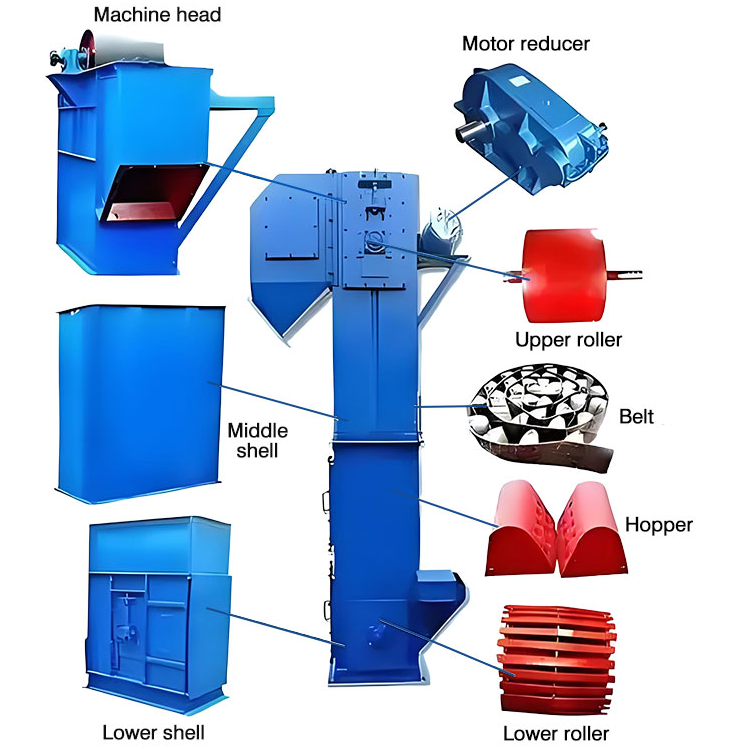

The belt bucket elevator TD160 mainly consists of a running section, upper section, lower section, intermediate casing, drive unit, and backstop brake.

Running section: Consists of buckets and a belt. The buckets are fixed to the belt to form a closed-loop system for scooping and conveying materials.

Upper section: Equipped with a drive roller, which drives the traction belt via a head roller, lifting materials from bottom to top.

Lower section: Equipped with a tension roller to adjust belt tension, ensuring smooth belt operation and preventing slippage or deviation.

Intermediate Casing: As the main structure of the elevator, it provides an enclosed space for material conveying, preventing dust leakage and protecting internal components from external interference.

Drive Unit: Provides power to the elevator, typically using a combination of a motor and reducer to drive the drive drum to rotate, which in turn drives the conveyor belt and buckets.

The belt bucket elevator TD160 achieves material conveying through a process of drive traction – bucket receiving – vertical lifting – unloading. After startup, the drive system drives the head drive drum to rotate, which in turn drives the conveyor belt to circulate through friction. The buckets, fixed to the conveyor belt, descend with the belt to the bottom inlet. The buckets scoop or receive material at the inlet and are then lifted upwards by the conveyor belt. When they reach the head drum, the buckets are overturned by centrifugal force and gravity, unloading the material into the head discharge chute, completing the vertical conveying process.

The belt bucket elevator TD160 covers low-to-medium output vertical conveying needs across multiple industries, adaptable to lifting heights of 3-20 meters, and compatible with various layouts in indoor and outdoor workshops and warehouses.

Grain Industry: Used in grain processing plants, grain depots, and feed mills for vertically lifting wheat, corn, soybeans, and other grain crops. Its unique bucket design effectively handles freshly threshed, moist grains, preventing material from clumping and ensuring smooth and rapid conveying.

Coal Industry: Stable conveying of coal materials with varying moisture levels, including wet coal and dry coal powder. Its sealed structure and wear-resistant properties effectively reduce dust leakage and equipment wear, meeting the continuous vertical transportation requirements of coal.

Building Materials Industry: Used for conveying powdery or granular materials such as cement, sand, and lime powder. Its large-capacity bucket and high-speed drive system meet the high-intensity, large-volume material lifting needs of building materials production.

Mining Industry: Used for vertically transporting small lump materials such as crushed ore and quartz sand. Its robust casing and wear-resistant rubber belt allow it to adapt to harsh mining conditions, ensuring the stability and safety of material conveying.

Lightweight Materials: Handles lightweight materials such as sawdust and plastic granules. Its arc-bottom bucket or special anti-static design effectively prevents blockages caused by static electricity or moisture, improving conveying efficiency.

High-Temperature Materials: Utilizing heat-resistant rubber belts, this equipment can convey materials with temperatures not exceeding 200℃, widely used in the metallurgical industry.

Although both the TD160 and chain bucket elevators belong to the category of bucket elevator equipment, they differ significantly in structure, performance, and applicable scenarios. Selection must be based on material characteristics and operating conditions.

Structure and Transmission Method: The TD160 uses a rubber conveyor belt and motor reducer drive, offering good belt flexibility and low operating noise; the chain bucket elevator uses a chain (plate chain/circular link chain) as the traction component, resulting in a more robust transmission structure, but with higher operating noise.

Material Compatibility: The TD160 model is suitable for granular, small-lump, and low-abrasion materials such as grains and feed, where the conveyor belt is easily scratched by sharp materials. Chain bucket elevators are wear-resistant, have high load-bearing capacity, and can transport heavy, highly abrasive materials such as ores and coke.

Performance and Maintenance: The TD160 model has a conveying capacity of 15-30 m³/h and a lifting height of 3-20 meters. Maintenance is simple, and conveyor belt replacement costs are low. Chain bucket elevators have a larger conveying capacity and a lifting height of ≤40 meters, but the chain requires regular lubrication, resulting in shorter maintenance cycles and higher costs.

Scenario Suitability: The TD160 model is suitable for low-to-medium load, low-noise scenarios such as grain and chemical industries. Chain bucket elevators are suitable for high-load, high-abrasion industrial scenarios such as mining and building materials industries.

DaHan Machinery's TD160 belt bucket elevator starts at $900. A detailed quote will be provided based on your specific needs. Price is influenced by various factors. In terms of materials, there's a cost difference between carbon steel and 304 stainless steel bodies; the latter is more suitable for applications requiring corrosion resistance. Functionally, the addition of features like variable frequency speed control, online monitoring, and CIP cleaning will affect the overall price. Power specifications, customized lifting height, and hopper type will also impact the final price. Please provide detailed production requirements, and we will create a detailed quote for you.

Dahan Machinery possesses independent design capabilities, allowing for customization of the frame material (carbon steel/stainless steel), lifting height, and additional functions according to customer needs. Core components are sourced from well-known brands, ensuring the stable and durable operation of the belt bucket elevator TD160. Equipped with a professional technical team, we provide one-stop service from selection consultation and solution design to commissioning and after-sales maintenance. Our products have passed quality testing and certification and are sold to many regions. With high-performance products and attentive service, we have won unanimous recognition from customers in the grain, mining, and chemical industries.

The belt bucket elevator TD160 uses a drive roller to continuously lift powdery, granular, and small lump materials. Its sealed structure prevents dust leakage, and multiple bucket types are suitable for different materials. Widely used in industries such as grain, coal, and building materials, it is a reliable choice for industrial vertical transportation.

Address:China,Yanjin county forest park gate to the west 1000 meters north road.