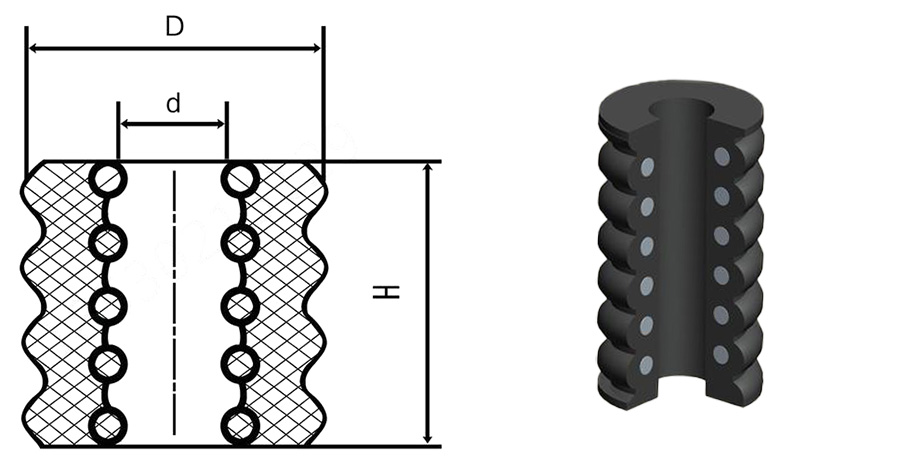

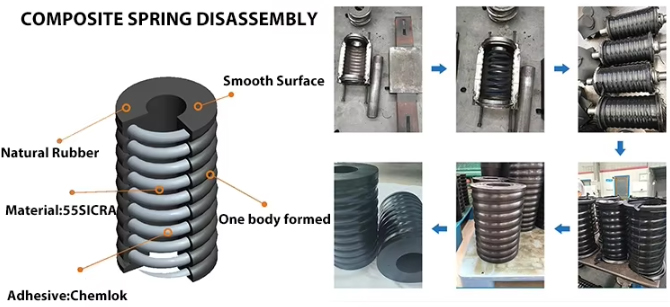

It is composed of a metal coil spring and high-quality vulcanized rubber wrapped around it.

![]()

![]()

![]()

Price:$7-$50/Set

Consult now and enjoy a 10% discount

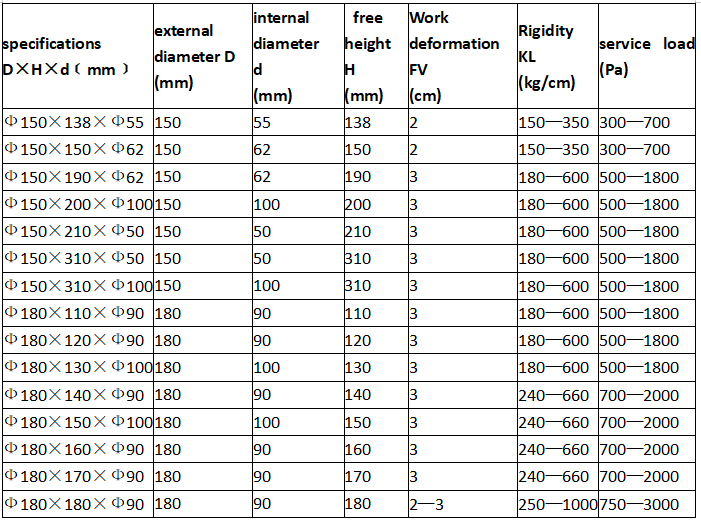

Material: Rubber

Working load:80-2800Pa

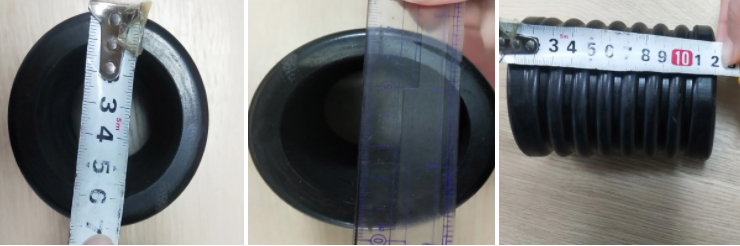

Outer diameter: 150-180mm

Inside diameter: 55-100mm

Free height: 110-310mm

Work deformation: 2-3cm

Service load: 300-700Pa

Application: Widely used in large-scale vibration machinery and equipment in mining, metallurgy, coal and other industries.

Commitment:

Composite spring is an elastic element that combines the advantages of metal spring and rubber spring. It is composed of metal spiral spring and high-quality vulcanized rubber coated on it. It overcomes the shortcomings of high stiffness of metal spring, small load-bearing capacity of rubber spring, poor shape and mechanical property stability, and has the advantages of high load-bearing capacity, large deformation, stable operation and short resonance interval.

A composite spring for vibrating screens is a spring that combines multiple materials or spring elements and plays an important role in vibrating screens. Here are some of the features of composite springs for vibrating screens:

1.Durability and extended life: The design structure of the composite spring can provide longer service life and better durability, reduce the frequency of replacement and maintenance, and reduce operating costs.

2.Vibration absorption and shock absorption: The composite spring design takes into account the vibration absorption characteristics, which can effectively reduce the transmission of vibration to the vibrating screen body and supporting structure, improve the working environment, and reduce noise.

3.Reduced vibration transmission: The design of the composite spring can effectively reduce the transmission of vibration to the entire vibrating screen system, protect the equipment and structure, and extend the service life of the equipment.

Composite springs can be made from various materials, but the most common type of composite material used is fiber-reinforced polymer (FRP) composites. These composites consist of a polymer matrix reinforced with high-strength fibers, such as carbon fiber or glass fiber. The choice of composite material depends on the specific requirements of the application, including desired strength, stiffness, and environmental conditions.

Composite springs refer to spring systems composed of two or more different types of springs. They can be combined in series, parallel or mixed, and each combination has different characteristics and uses. The following introduces three common types of composite springs:

Series composite springs: Multiple springs are connected end to end, with a lower total stiffness than a single spring and a longer total stroke than a single spring, which is suitable for occasions that require a larger stroke.

Parallel composite springs: Multiple springs are connected side by side, with a higher total stiffness than a single spring and a shorter total stroke than a single spring, which is suitable for occasions that require a larger stiffness.

Hybrid composite springs: Combining the series and parallel methods, the characteristics can be customized as needed, and the application range is wider.

Composite springs offer several advantages over traditional steel springs:

Weight reduction: Composite materials, such as fiberglass or carbon fiber-reinforced polymers, are lightweight and have a high strength-to-weight ratio. Using composite springs can significantly reduce the overall weight of the system, leading to improved fuel efficiency (in automotive applications) and increased payload capacity (in aerospace applications).

Corrosion resistance: Unlike steel springs, composite springs are inherently resistant to corrosion. This makes them suitable for applications where exposure to moisture, chemicals, or harsh environments is a concern.

Fatigue resistance: Composite materials have excellent fatigue properties, allowing composite springs to withstand repeated loading cycles without experiencing significant degradation in performance or fatigue failure. This results in longer service life and reduced maintenance requirements.

Design flexibility: Composite springs can be designed and manufactured in various shapes, sizes, and configurations to meet specific application requirements. They can be tailored to provide desired stiffness, damping characteristics, and load-carrying capacity.

Vibration damping: Composite materials have inherent damping properties, which can help reduce vibrations and improve ride comfort in applications such as automotive suspension systems.

| Features | Steel springs | Composite spring |

| Material | High carbon steel or alloy steel | Metal spring + rubber layer |

| Elasticity | Good elasticity, strong recovery | Good elasticity, strong recovery force, and rubber cushioning performance |

| Vibration reduction effect | General vibration reduction effect | Good vibration reduction effect, can effectively absorb vibration energy |

| Wear resistance | Good wear resistance | The rubber layer has good wear resistance and extends service life |

| Load carrying capacity | Strong load-bearing capacity | Strong load-bearing capacity and large deformation |

| Corrosion resistance | General, easily affected by humid environment | Corrosion-resistant rubber can be selected, with good corrosion resistance |

| Noise | Produces some noise | Low noise |

Composite springs are widely used in vibrating screen machinery, mainly used to support and control the vibration movement of the vibrating screen. It is particularly suitable for large-scale vibrating equipment in mining, coal, metallurgy and other industries. The following is a detailed introduction to the application of vibrating screen composite springs in these industries:

Mining industry: In the mining industry, vibrating screen composite springs can provide strong elastic support and shock absorption effect, and are used to support the vibrating parts of the vibrating screen, such as screen frames, screen meshes, etc.

Coal industry: In the coal industry, composite springs can provide appropriate elasticity and vibration amplitude to help coal screening equipment achieve efficient screening and grading.

Metallurgical industry: In the metallurgical industry, composite springs can adapt to high temperature and corrosive environments, provide stable elastic support, and ensure the normal operation of the vibrating screen and accurate screening effect.

Other industries: Composite springs are also used in large-scale vibrating equipment in other industries, such as building materials, chemicals, food processing, etc. In these industries, composite springs can provide appropriate elasticity and vibration amplitude to ensure sufficient screening and screening efficiency of materials.

When selecting composite springs for vibrating screens, you need to consider the following factors:

Load requirements: Determine the load range and working conditions required for the vibrating screen. This includes the size, direction and frequency of changes in the load. Make sure the composite spring you choose can handle the expected loads and maintain consistent performance.

Elastic properties: Consider the required elastic properties of the vibrating screen, such as stiffness and natural frequency. These characteristics will directly affect the vibration frequency and amplitude of the vibrating screen. Depending on the specific application needs, the appropriate composite spring is selected to provide the required elastic properties.

Material Selection: Select the appropriate composite material based on the requirements of the application. Common composite spring materials include carbon fiber reinforced polymer (CFRP), glass fiber reinforced polymer (GFRP) and aramid fiber reinforced polymer (AFRP). Each material has different performance characteristics such as strength, stiffness and durability. Select the appropriate material based on the application environment and requirements.

Lifespan and durability: Consider the lifespan and durability requirements of the vibrating screen. Composite springs should be able to withstand extended use and repeated load cycles without significant performance degradation. Make sure to choose a composite spring with good fatigue life and durability.

Cost and Manufacturing: Consider the cost and manufacturing feasibility of composite springs. The manufacture of composite springs often requires specialized processes and equipment. Make sure the composite spring you choose is cost and manufacturing feasible and will meet budget and production requirements.

Xinxiang Dahan is a manufacturer of composite springs and other accessories. Our company has mature technology, rich practical experience, perfect testing methods and quality assurance system. Springs of various models and specifications are available, direct supply from stock and direct sales from manufacturers.

The composite springs produced by Xinxiang Dahan have the following characteristics:

High-quality rubber materials: Made of high-quality metal and rubber materials, with good wear resistance and durability.

Exquisite craftsmanship: Advanced production technology and equipment are used to ensure the stability and reliability of rubber springs.

Customized service: According to customer needs, customized spring products are provided to meet the needs of different equipment.

Address:China,Yanjin county forest park gate to the west 1000 meters north road.