Made of steel, are elastic, can store and release mechanical energy, and are widely used in various machines and equipment.

![]()

![]()

![]()

Price:$0.60/piece-$3.00/piece

Consult now and enjoy a 10% discount

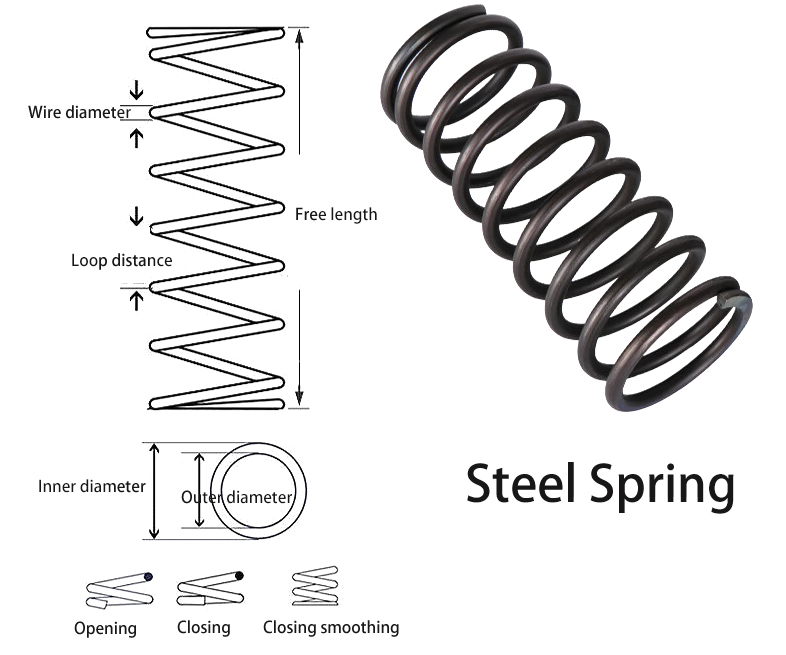

Wire diameter: 4.5-18mm

Inner diameter: 36-70mm

Overall height: 145-180mm

Advantages: Made of high-strength steel, it has good wear resistance and fatigue resistance, can withstand long-term vibration and impact, has good elasticity, can effectively absorb vibration and reduce the impact force of equipment. Application: It can be used in vibro sifter, stainless steel vibrating screen, ultrasonic vibrating screen, linear vibrating screen and other vibrating machines.

Commitment: Free Shipping/5 Days Delivery/30-Day Returns/Support Customization

Steel springs are usually used in mechanical equipment, vehicle running mechanisms, suspensions and other shock absorbers, double-decker buses, trucks and other industrial machinery to play a role in shock absorption and buffering.

Steel springs are generally of equal pitch, with shapes such as cylindrical, conical, convex and concave, and a small number of non-circular shapes. There is a certain gap between the circles. When subjected to external loads, the springs shrink and deform to store deformation energy.

According to the type of vibrating screen and the shape and function of the spring, the steel spring of the vibrating screen can be divided into the following categories:

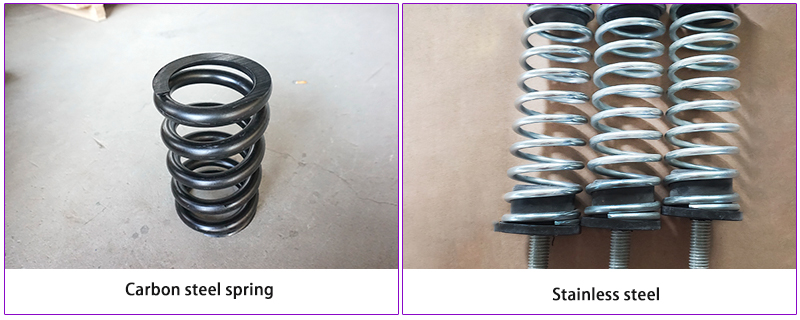

Classification by spring material

1. Carbon steel spring: It has good elasticity, strength and fatigue resistance and is a commonly used spring material.

Alloy steel spring steel: It has higher strength, heat resistance and corrosion resistance and is suitable for special working conditions.

2. Classification by spring shape

Compression steel spring: It shortens when subjected to force and is used to generate downward pressure.

Suspension steel spring: The suspension spring can support the weight of the vibrating screen and maintain the stability of the overall structure of the vibrating screen.

In the vibrating screen, steel springs, as one of the important components, play a variety of key roles, including but not limited to the following:

1. Supporting role: Steel springs can provide the stable supporting force required by the vibrating screen, ensuring that the overall structure of the vibrating screen is stable and will not loosen or deform due to vibration.

2. Shock absorption and damping: The spring has good elasticity and shock absorption performance, which can effectively absorb the vibration and impact force generated by the vibrating screen during operation, reducing the impact on the equipment and the surrounding environment.

3. Protecting equipment: The spring can play a buffering and protective role to prevent the vibrating screen from being damaged when it is subjected to external impact or vibration, and extend the service life of the equipment.

Vibrating screen steel springs are widely used and are commonly used in vibrating screen machines in ore dressing, building materials, chemical industry, metallurgy, coal and other industries.

The following are several specific application scenarios of steel springs in the vibrating screen industry:

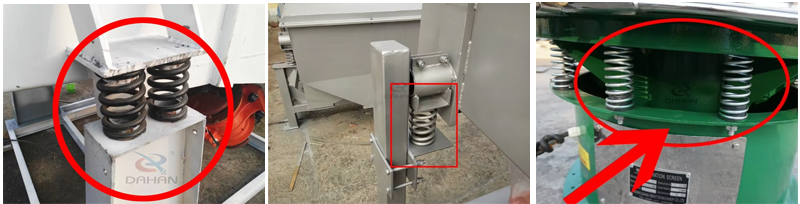

Vibrating screen machine suspension system: Steel springs are usually used in the suspension system of the vibrating screen machine to support and absorb shock. They are installed at the bottom or four corners of the vibrating screen machine to support and fix the body of the screen machine and provide elastic support so that the vibrating screen can adapt to different working conditions and vibration conditions.

Vibration transmission device: Steel springs are also used in the vibration transmission device of the vibrating screen machine, such as the connection between the vibration motor and the screen machine. The steel spring transmits the vibration generated by the vibration motor to the vibrating screen machine through devices such as connecting rods or couplings, so that it produces effective screening movement.

Vibrating screen machine screen frame support: Steel springs can also be used as support elements for the vibrating screen machine screen frame. They are installed around the screen frame to support and buffer, absorb external shocks and vibrations, protect the screen frame from damage, and provide a stable screening effect.

Application: rotary vibrating screen, ultrasonic vibrating screen, filter screen, high-frequency vibrating screen, direct discharge screen, linear vibrating screen.

High strength and durability

Vibrating screen steel springs are usually made of high carbon steel or alloy steel. They have high strength and hardness, can withstand the working load and vibration force of the vibrating screen machine, and have a long service life.

Good elasticity and resilience

The steel spring of the vibrating screen has good elasticity and can produce elastic deformation during the working process of the vibrating screen machine, thereby achieving vibration and movement of the screened materials. They quickly return to their original shape, ensuring the stability and efficiency of the screening process.

Adaptable

The vibrating screen steel springs can be customized and adjusted according to different vibrating screen machine sizes and work requirements. They can adapt to different vibration frequencies and amplitudes to meet the screening needs of different materials.

Good corrosion resistance

The steel springs of the vibrating screen have undergone special surface treatment or are made of corrosion-resistant materials, which can resist corrosion and oxidation in harsh working environments and extend their service life.

| Model | Inner diameter D (mm) | Overall height L(mm) | Wire diameter d (mm) |

| Ф70×150×Ф8 | 70 | 150 | 8 |

| Ф70×150×Ф10 | 70 | 150 | 10 |

| Ф70×150×Ф12 | 70 | 150 | 12 |

| Ф70×180×Ф12 | 70 | 180 | 12 |

| Ф70×180×Ф14 | 70 | 180 | 14 |

| Ф70×180×Ф16 | 70 | 180 | 16 |

| Ф70×180×Ф18 | 70 | 180 | 18 |

| Ф76×150×Ф10 | 76 | 150 | 10 |

| Ф36×145×Ф4.5 | 36 | 145 | 4.5 |

| Ф36×145×Ф5.0 | 36 | 145 | 5.0 |

| Ф36×145×Ф5.5 | 36 | 145 | 5.5 |

| Ф36×145×Ф6.0 | 36 | 145 | 6.0 |

Whether spring steel or stainless steel is better depends on the specific application and the priorities for the project. Here's a breakdown of their key properties and when to choose one over the other:

Steel spring: Ideal for applications requiring high load-bearing capacity and repeated cycles of stress and strain. Generally more affordable than stainless steel.

Stainless steel spring: Resists rust and corrosion, making it suitable for harsh environments and applications exposed to moisture or chemicals.Some grades of stainless steel can withstand high temperatures.Generally more expensive than spring steel.

Below we compare rubber springs and steel springs in tabular form:

| Features | Rubber spring | Steel springs |

|

|

|

| Material | Natural rubber, synthetic rubber | Spring steel (carbon steel, alloy steel) |

| Main features | Good elasticity, wear resistance, oil resistance, good insulation, light weight | High strength, good rigidity, long fatigue life |

| Advantages and disadvantages | Wide elastic range, good buffering performance, but weak load-bearing capacity, easy to age, greatly affected by temperature; | Strong load-bearing capacity, good rigidity, but small elastic range, easy to produce fatigue, relatively complex manufacturing process; |

| Typical applications | Automobile suspension, shock absorber, seal, cushion, shockproof foot pad | Automobile suspension, mechanical equipment, precision instruments, household appliances, electronic products |

| Working environment | Suitable for environments with large vibration and impact, and occasions requiring buffering and shock absorption; | Applicable to occasions requiring high strength and high rigidity, and occasions with relatively stable working environment; |

| Cost | Relatively low | Relatively high |

When choosing a suitable vibrating screen steel spring, you can consider the following key factors:

Load requirements: First, the load requirements of the vibrating screen machine need to be determined, including vibration force, vibration frequency, amplitude and other parameters. Select the strength and stiffness of the spring according to the load requirements to ensure that it can withstand the required load and maintain a stable working condition.

Vibration characteristics: Different vibrating screen machines may have different vibration characteristics, such as vibration frequency and amplitude requirements. When selecting a spring, you need to ensure that its vibration characteristics match the requirements of the vibrating screen machine to achieve good vibration effects and screening efficiency.

Environmental conditions: Consider the working environment conditions of the vibrating screen machine, such as temperature, humidity, corrosiveness, etc. Select spring materials with appropriate durability and corrosion resistance or perform special surface treatments according to environmental conditions to ensure that the spring can operate stably for a long time in harsh environments.

Design and quality reliability: Choose vibrating screen steel springs with good design and quality reliability to ensure that they are not easy to break, deform or fail during long-term use. You can refer to the supplier's product information, technical specifications, user reviews and other information to evaluate the design and quality reliability of the spring.

Cost-effectiveness: When selecting steel springs for vibrating screens, cost-effectiveness factors need to be considered comprehensively. In addition to the price of the spring itself, factors such as its service life, maintenance costs, and replacement cycles must also be considered to select an economical and practical spring.

The best choice is to select the most suitable vibrating screen steel spring based on specific application needs and working conditions based on communication and consultation with vibrating screen machine manufacturers, suppliers or professional engineers.

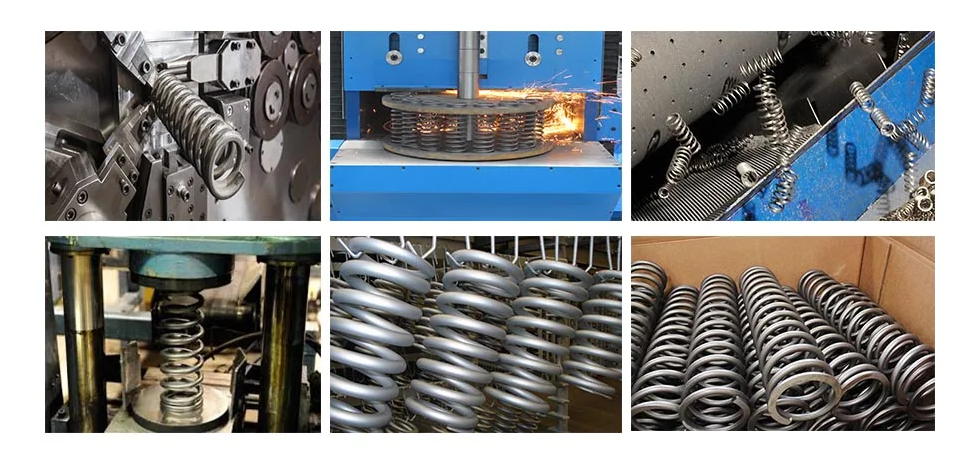

Xinxiang Dahan Vibrating Screen Steel Spring Manufacturer is a manufacturer specializing in the production of vibrating screen steel springs with rich experience and technical strength. We use high-strength steel to create durable springs that can withstand heavy loads and frequent vibrations. We focus on product quality control to ensure that each spring has stable elasticity and reliable performance. In addition, we provide customized solutions, designing and manufacturing springs according to customer needs and application scenarios to meet the requirements of different industries. We have won the trust and cooperation of our customers with competitive prices, on-time delivery and excellent customer service.

Address:China,Yanjin county forest park gate to the west 1000 meters north road.