The concrete batching screening machine uses the principle of vibrating screening to separate concrete aggregates according to particle size, remove aggregates that are too large or too small, and ensure the uniformity and quality of concrete.

![]()

![]()

Price:$800.00-$3,000.00/Set

Consult now and enjoy a 10% discount

Mesh number: 400 mesh

Feeding particle size: 0.074-10mm

Capacity: 0.12-20 tons/hour

Motor Power: 2*(0.4-3.7)kw

Application: Concrete mixing stations, precast component plants and other fields are an essential process in the concrete production process. Through screening, aggregates that are too large or too small in concrete can be effectively removed.

Commitment:

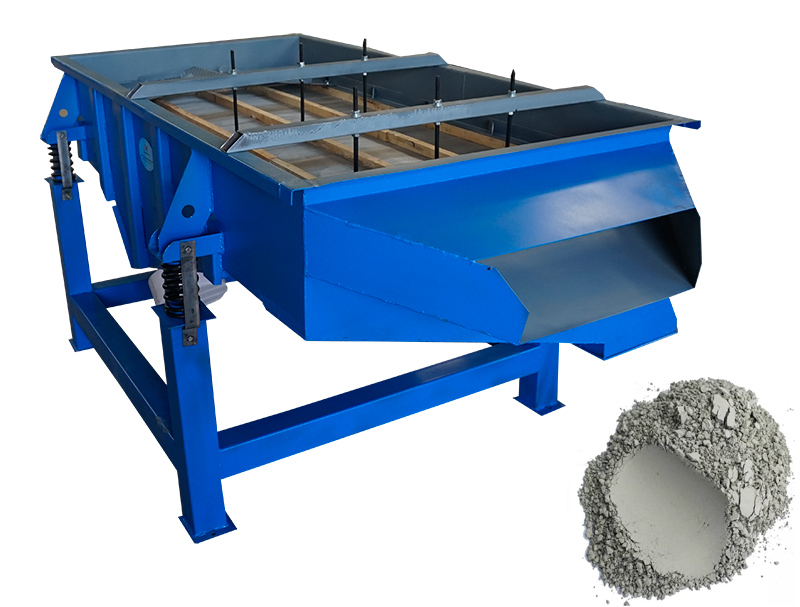

The concrete batching for sieving machine is a special equipment used to screen and classify raw materials such as aggregate and sand in concrete batching. It plays an important role in concrete production. It ensures that the particle composition of concrete ingredients meets the requirements through precise sieving and classification. The concrete batching for sieving machine has the advantages of efficient production capacity, flexible adjustment and control, and reliable working performance. It is widely used in material sieving and classification in concrete production and other industries.

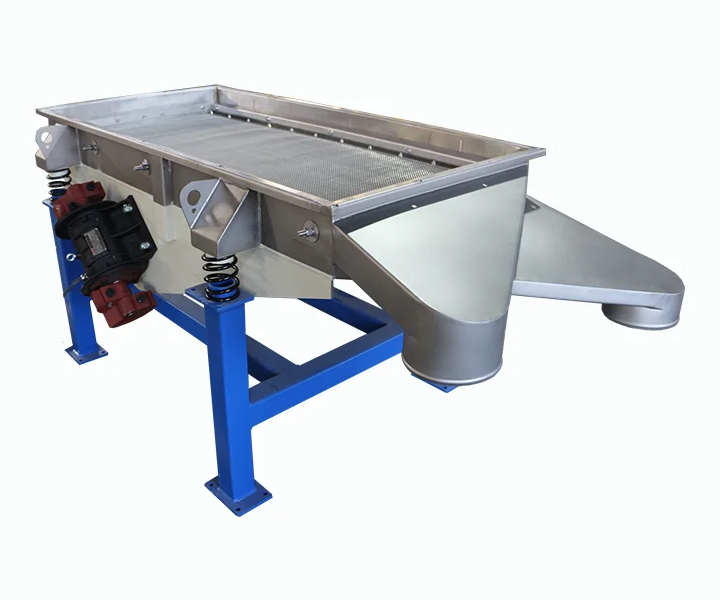

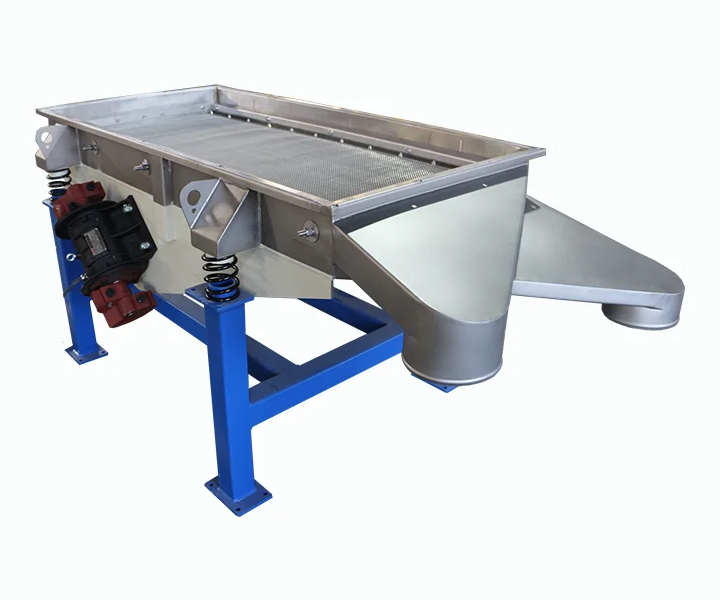

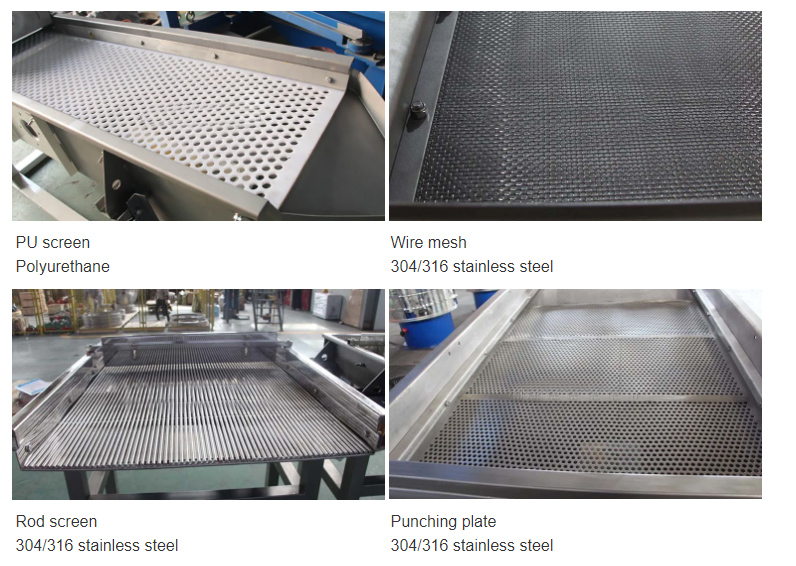

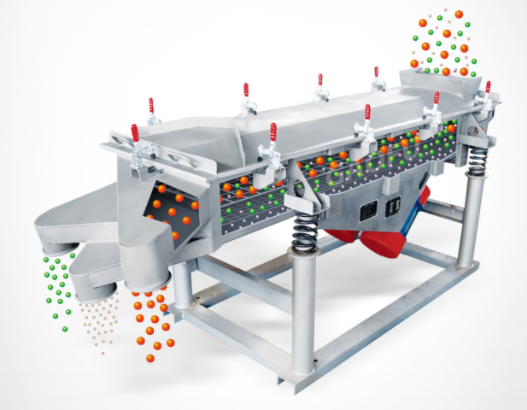

Concrete batching for sieving machines usually consist of vibration motors, screens, hoppers and support structures. It uses the excitation effect of the vibration motor to screen and classify the raw materials on the screen. sieving machines usually have multi-layer screens that can screen raw materials of different particle sizes at the same time.

Concrete batching for sieving machines are widely used in the batching process in concrete production. It can accurately screen and classify raw materials such as aggregate and sand to obtain particle composition that meets the requirements of concrete formulas. concrete batching for sieving machines can also be used in other industries, such as mining, building materials, metallurgy and other fields for material sieving and classification.

1. Precise sieving effect: The concrete batching for sieving machine can achieve precise sieving and classification of raw materials through the combination of different screens and the adjustment of vibration frequency, ensuring that the particle composition of concrete batching meets the requirements.

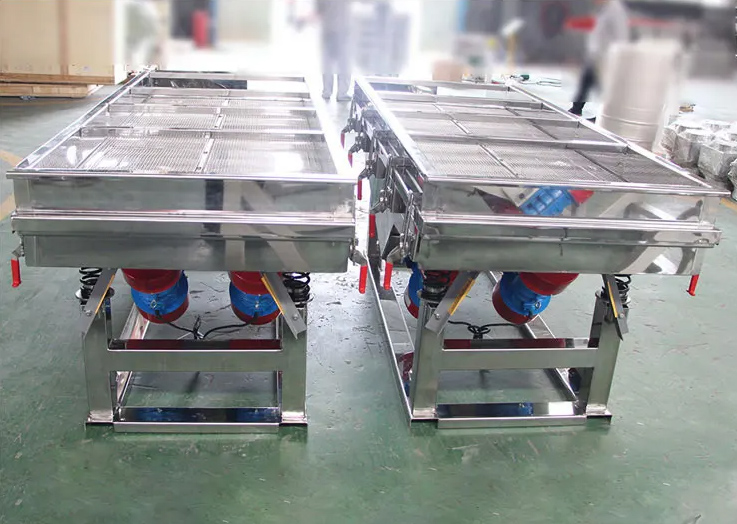

2. Efficient production capacity: The concrete batching for sieving machine has efficient sieving speed and processing capacity, and can quickly process a large amount of raw materials and improve production efficiency.

3. Flexible adjustment and control: concrete batching for sieving machines usually have adjustable vibration frequency and screen angle, which can be flexibly adjusted and controlled according to different batching requirements.

4. Reliable working performance: The concrete batching for sieving machine adopts high-quality materials and structural design, has stable and reliable working performance, and can run continuously for a long time, reducing faults and downtime.

The working principle of the concrete batching for sieving machine is to screen the raw materials on the screen through the vibration force generated by the vibration motor. The raw materials enter the sieving machine from the hopper. The excitation of the vibration motor causes the particles on the screen to move relative to each other. The larger particles are blocked on the upper screen and the smaller particles fall through the screen into the lower screen or collecting trough. This enables grading and sieving of raw materials.

After a concrete production company introduced a concrete batching for sieving machine in the batching process, it effectively improved the accuracy of batching and production efficiency. The sieving machine can screen raw materials according to the required particle size to ensure the quality and stability of concrete. At the same time, the efficient working capability of the sieving machine makes the batching process faster and more continuous, improving production efficiency. By using the concrete batching for sieving machine, the company achieved higher batching accuracy and production efficiency, and achieved obvious economic benefits.

Address:China,Yanjin county forest park gate to the west 1000 meters north road.