Pneumatic screening machine is made of 304 stainless steel and features a sealed structure specifically designed for certain materials, ensuring efficient screening within a completely enclosed system.

Price: $450.00-$3200.00/Set

Mesh: 500 mesh or 0.028mm

Output: 100-3300 kg/hour

Diameter: 600-2000mm

Number of Layers: 1-5 layers

Material: 304 stainless steel, 316 stainless steel

Motor power: 0.25kW to 2.2kW or customized

Power supply: 220/240/380/415/450V can be used. 50 or 60Hz.

Applicable materials: 3D printing materials, metal powder, graphite powder, titanium alloy powder, pharmaceutical raw materials, battery-grade lithium salts.

Commitment: Free Shipping/5-Day Delivery/30-Day Returns/Support Customization

Pneumatic Screening Machine is a specialized screening device designed for easily oxidized, moisture-sensitive, toxic, or high-value-added materials such as metal powders and graphite powders. Through the synergistic effect of a sealed chamber and inert gas, air is isolated during the screening process, fundamentally solving industry pain points such as material oxidation and deterioration, and dust pollution. It features low noise, high efficiency, and quick screen changes (only 3-5 minutes). Its fully enclosed structure is suitable for screening and filtering materials such as liquids, powders, and liquefaction products. The finest screening is up to 500 mesh or 0.028mm, and the smallest filtration is down to 5 microns. It can simultaneously perform impurity removal and grading, and can screen one to five layers of screens, performing two to six levels of sorting or filtration simultaneously. We also support non-standard customization, allowing us to modify the shape and position of the discharge port, motor power, and add hoppers for easier material feeding, tailored to your site conditions.

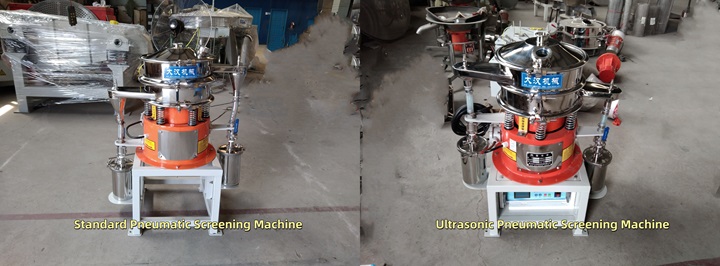

Pneumatic screening machines are mainly divided into two categories: ordinary pneumatic screening machines and ultrasonic pneumatic screening machines. Both are based on a core principle of airtight protection and inert gas isolation, suitable for screening easily oxidized, toxic, and harmful materials. The differences lie only in the screening auxiliary technology and applicable scenarios.

Ordinary Pneumatic Screening Machine: As a basic protective screening device, its core focus is on preventing material oxidation and meeting environmental protection requirements. It adopts a fully enclosed structure, with the screen body and inlet/outlet protected by welded seals and silicone sealing rings, effectively preventing air ingress and dust leakage. It is suitable for medium to coarse screening of materials such as lithium battery positive and negative electrode materials, common metal powders, and easily oxidized chemical additives.

Ultrasonic Pneumatic Screening Machine: This is an upgraded device that adds ultrasonic technology to the ordinary model, specifically designed for ultrafine and easily agglomerated materials. It retains the fully enclosed protection and inert gas protection functions, while adding an ultrasonic transducer to transmit 38kHz high-frequency vibration to the screen. This high-frequency vibration breaks down surface tension and electrostatic adsorption in materials, effectively solving the problem of screen clogging in ultrafine powders. It increases screen throughput by 5-20 times, making it suitable for high-value-added fine screening of materials such as 3D printing alloy powders, titanium alloy powders, high-end pharmaceutical raw materials, and battery-grade lithium salts.

A pneumatic screening machine supports precise gas control, allowing oxygen content to be flexibly adapted to different material requirements. Combined with a stable vibration system or ultrasonic technology, it achieves high grading accuracy and low clogging rate, adapting to a diverse range of materials from conventional particles to ultrafine powders.

Fully enclosed structure: The gas-protected screen uses a double-sealed design of silicone and metal, completely preventing dust leakage and air ingress, meeting the high safety standards of the chemical and pharmaceutical industries.

Inert gas protection: By injecting inert gases such as nitrogen and argon, an oxygen-free or low-oxygen environment is created within the screening chamber, preventing oxidation, combustion, or explosion of materials upon contact with oxygen.

Explosion-proof motor and pressure reducing valve: Optional explosion-proof motor and pressure reducing valve, suitable for flammable and explosive material scenarios, ensuring safe and stable equipment operation.

Multi-layer screen design: Supports 1-5 layers of screen grading, achieving up to 6 levels of grading, meeting diverse grading needs.

Airflow-assisted grading: By adjusting the gas flow rate, the problem of ultrafine powder agglomeration can be solved.

Multi-industry applicability: Widely used in chemical, pharmaceutical, food, metallurgical, and electronic materials industries, especially suitable for grading high-value-added, high-purity materials.

Special material handling: For materials with strong adsorption, high static electricity, and easy agglomeration, the gas-protected screen effectively prevents material deterioration and dust explosion through an inert gas environment and anti-static device.

Compatible with viscous and powder materials: The fully enclosed structure and gas protection system allow the equipment to process both powdery and viscous materials simultaneously.

The core components of the pneumatic screening machine are designed around three core functions: enclosed protection, gas control, and grading operation. These components work together to achieve anti-oxidation, dust prevention, and high-speed grading.

Sealed Screen Body:The screen body is the core load-bearing structure, integrally formed from 304/316L stainless steel, including the screen frame, screen fixing device, and upper and lower covers.

Vibration Motor:The gas-protected screen uses a vertical vibration motor as the excitation source, with eccentric weights installed at both ends of the motor.

Screen Structure:The screen is one of the core components of the gas-protected screen; its material and specifications are selected according to the material characteristics.

Gas Conveying Device:The gas protection system injects inert gas into the screening chamber through a gas protection hose to replace the air inside, creating a low-oxygen or oxygen-free environment.

Anti-static Device:For materials prone to static electricity, the gas-protected screen is also equipped with an anti-static device. This device effectively eliminates static electricity generated during screening, preventing material from clogging the screen due to static electricity or causing safety hazards such as dust explosions.

Observation Port and Discharge Valve:To facilitate operator observation of the screening process and control of material discharge, the gas-protected screen is also equipped with an observation port and discharge valve.

During operation, inert gas is first introduced into the sealed screening chamber to replace the internal air, reducing the oxygen concentration below the material's oxidation threshold. Then, a vibrating motor drives the screen surface to complete material grading or impurity removal. During screening, the inert gas is continuously replenished through circulation, and a pressure monitoring system continuously regulates the chamber pressure, ensuring both anti-oxidation effects and preventing dust leakage, achieving the dual goals of environmental zero pollution and material protection.

The Pneumatic screening machine is suitable for special materials requiring air isolation, covering chemical, new energy, pharmaceutical, and 3D printing alloy powder industries. It prevents material oxidation and deterioration, and the leakage of toxic gases, meeting the screening needs of various industries for material purity and production safety.

Metal powders: Metal powders such as aluminum powder, titanium powder, and molybdenum powder readily react with oxygen, leading to oxidation or combustion, and require screening in an oxygen-free environment. The gas protection screen creates a low-oxygen environment by injecting inert gases such as nitrogen and argon, preventing oxidation and dust explosions.

Non-metallic powders: Ultrafine powders such as silicon carbide and white corundum are prone to agglomeration and require high-precision sieving. Gas-protected screens utilize ultrasonic technology to break the surface tension of materials, solving the problem of screen clogging, and achieving a sieving accuracy of up to 5μm.

Chemicals and New Materials: Materials sensitive to moisture and oxygen, such as battery-grade lithium salts and electromagnetic powders, require strict environmental control. Gas-protected screens, through a fully enclosed structure and humidity regulation, ensure that materials are sieved in a dry environment, preventing performance degradation.

Food and Pharmaceuticals: Food raw materials such as milk powder and starch require moisture and contamination prevention, meeting hygiene standards. Gas-protected screens, through a fully enclosed structure and inert gas protection, prevent moisture absorption, agglomeration, and cross-contamination.

Vulgar and Slurry Materials: Materials with high viscosity and poor flowability, such as ceramic slurries and resins, require special sieving methods. The fully enclosed structure of the gas-protected screen prevents slurry leakage, while separation is achieved through a vibrating motor.

| Model |

Screen Diameter (mm) |

Sieving Area (m2) |

Screen Size (mesh) |

Layers |

Power (KW) |

| DHC-400 | 340 | 0.091 | 80-600 | 1~3 | 0.18 |

| DHC-600 | 540 | 0.229 | 0.25 | ||

| DHC-800 | 730 | 0.418 | 0.55 | ||

| DHC-1000 | 900 | 0.636 | 0.75 | ||

| DHC-1200 | 1100 | 0.95 | 1.1 | ||

| DHC-1500 | 1400 | 1.539 | 1.5 | ||

| DHC-1800 | 1700 | 2.269 | 2.2 | ||

| DHC-2000 | 1886 | 2.792 | 2.2 |

The pneumatic screening machine is significantly superior to ordinary vibrating screens in terms of oxidation prevention, moisture prevention, explosion prevention, and screening accuracy. Ordinary vibrating screens, however, have advantages in structural simplicity, ease of maintenance, and cost.

Functional Characteristics Comparison: The pneumatic screening machine creates an oxygen-free or low-oxygen environment by injecting inert gases such as nitrogen and argon, effectively preventing the oxidation and deterioration of materials such as metal powders and activated carbon, while also reducing humidity to prevent hygroscopic materials from clumping. In terms of screening, the combination of high-frequency vibration and multi-layer screens achieves 6-level grading with a fineness of up to 500 mesh and a penetration rate of 99%. Ordinary vibrating screens rely on basic oscillation motion, using screen stacking to grade medium and coarse materials. When screening fine powders, they are prone to agglomeration and clogging, requiring frequent cleaning. They also have weak moisture and explosion prevention capabilities, making them only suitable for applications with low environmental sensitivity.

Comparison of Applicable Scenarios: Pneumatic screening machines are designed for high-value-added, highly sensitive materials, covering industries such as chemical, pharmaceutical, food, metallurgy, and electronic materials, meeting requirements for oxidation prevention, moisture prevention, explosion prevention, and multi-level grading. Ordinary vibrating screens are widely used in basic industries such as mining, construction, and metallurgy, processing large-scale heavy materials such as coal, ore, and sand, or in scenarios with lower precision requirements such as feed processing and sand and gravel sorting, meeting coarse screening needs at a low cost.

Comparison of Structure and Maintenance: Pneumatic screening machines have a complex structure, integrating components such as a gas circulation device, explosion-proof motor, and ultrasonic power supply. The fully enclosed design requires regular checks of sealing and gas flow. Although the screen replacement uses a quick-release design, the overall maintenance cost is higher. Ordinary vibrating screens have a simple structure, consisting of a screen box, vibrating motor, and screen, making operation and maintenance convenient. Screen replacement is frequent, but parts are highly interchangeable, resulting in low maintenance costs, making them suitable for companies with limited budgets or weaker technical capabilities.

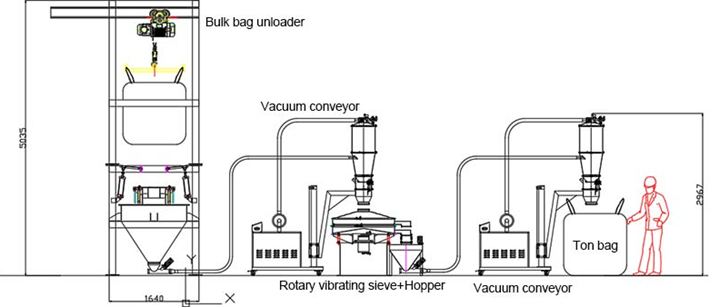

As core equipment for screening special materials, pneumatic screening machines can be deeply integrated with feeding stations, vacuum feeders, and packaging machines to create a closed-loop conveying-screening-packaging integrated production process. This ensures material protection against oxidation and contamination while improving production continuity and efficiency.

Pneumatic screening machine + feeding station: Enables contactless material feeding. The feeding station, with its sealed hopper and dust cover design, prevents dust leakage during material feeding and prevents air from entering subsequent systems. After pre-treatment at the feeding station, the material is directly fed into the gas-protected screen inlet through a sealed pipeline, ensuring no contact with air throughout the process and guaranteeing anti-oxidation effectiveness from the source.

Pneumatic screening machine + vacuum feeder: Utilizing negative pressure adsorption, the vacuum feeder forms a closed conveying link with the pneumatic screening machine. The feeder adsorbs material from the hopper or feeding station and precisely feeds it into the gas-protected screen through a sealed pipeline. The conveying process is dust-free and air-free, perfectly matching the airtight protection requirements of the pneumatic screening machine. The two working together enable automated continuous feeding, reducing manual intervention and preventing oxidation or contamination of materials during transport.

Pneumatic screening machine + packaging machine: The pneumatic screening machine's outlet connects to the packaging machine's inlet via a sealed joint. Qualified screened material directly enters the packaging machine for sealing. The entire process is conducted in a closed environment, allowing inert gas to enter the packaging container simultaneously with the material, further isolating it from air and extending the material's shelf life.

We customize fully enclosed screening systems for customers in various industries, incorporating inert gas protection and ultrasonic anti-clogging functions tailored to material characteristics. These systems are integrated with feeding and packaging equipment, providing comprehensive services from solution design to after-sales support.

Organic Pigment Anti-oxidation Screening: Chemical companies producing red organic pigments often experience oxidation and discoloration during traditional screening processes due to air contact, resulting in a finished product qualification rate of only 82% and dust leakage leading to complaints. We customized three ultrasonic pneumatic screening machines, using 316L stainless steel enclosed screen bodies. Nitrogen gas is introduced to control the oxygen content within the chamber to ≤0.5%, forming a linked production line with an enclosed feeding station and vacuum feeder. Pigment oxidation rate is reduced to below 1%, and the finished product qualification rate is increased to 99%.

Ternary Cathode Material Fine Grading: Lithium battery material manufacturers producing ternary cathode materials often experience agglomeration and screen clogging due to ultrafine powder, and exposure to air easily leads to moisture absorption and oxidation, affecting battery performance. Four custom-designed ultrasonic pneumatic screening machines are equipped with a high-frequency ultrasonic system to break up agglomerates. The screen body is protected by argon gas throughout the process, and an automated packaging machine integrates screening and packaging. Screen throughput is increased by 18 times, grading accuracy reaches ±2μm, and material moisture content is consistently below 0.02%.

Antibiotic raw material anti-contamination screening: Pharmaceutical companies producing cephalosporin antibiotic raw materials often find traditional screening equipment prone to residue buildup and difficult cleaning, and the material is susceptible to moisture and deterioration upon contact with air. Two custom-designed all-stainless steel pneumatic screening machines are provided, featuring a quick-release, dead-angle-free structure, mirror-polished inner walls, sterile nitrogen gas to replace air, and an online cleaning system. The material cross-contamination rate is 0%, moisture and deterioration problems are completely solved, and cleaning time is reduced by 60%.

Dahan Machinery's pneumatic screening machines start at $450, with the specific price depending on equipment specifications, material configuration, and customization requirements. The basic model is suitable for screening conventional and special materials, equipped with a standard sealed structure and basic gas control system. Upgrading to 316L stainless steel, ultrasonic anti-clogging mesh devices, high-precision oxygen concentration monitoring systems, or adjusting the screen size, number of screening layers, and the shape and position of the inlet and outlet, as well as the motor power, will increase production costs. Therefore, a detailed quotation will be provided based on your material characteristics, throughput, protection requirements, and other specific needs.

Dahan Vibration Machinery Co., Ltd. specializes in customized screening equipment for special materials. Our pneumatic screening machines include both ordinary and ultrasonic gas-protected screens, precision-manufactured using 304/316L stainless steel, achieving industry-leading sealing performance and precise oxygen content control. We support full-process customization with fast delivery in 7-15 days. Equipped with a professional screening laboratory, we offer free material screening tests and can recommend suitable customized screening equipment based on your production needs and site conditions. Our equipment is sold globally, providing solutions to screening problems encountered in production.

The pneumatic screening machine, with its integrated screening and protection design, retains the high-speed grading capability of conventional screening machines while solving the storage and processing problems of special materials. It provides a safe, high-speed, and clean solution for the production of high-requirement materials and is an important piece of equipment for modern industrial precision production.

Address:China,Yanjin county forest park gate to the west 1000 meters north road.