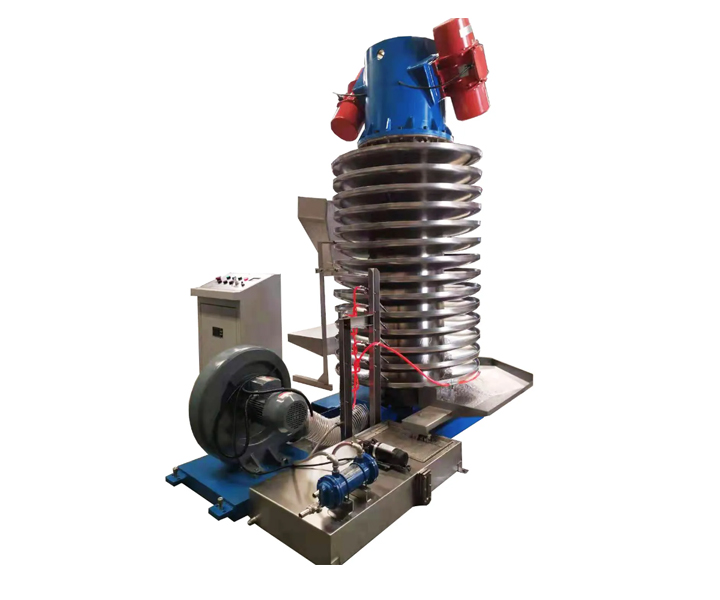

spiral vibrating dryer combines spiral movement and vibration to efficiently dry materials, offering uniform drying, fast drying times, gentle handling, and energy efficiency in various industrial applications.

![]()

![]()

![]()

Price:$500.00 - $20,000.00/Set

Consult now and enjoy a 10% discount

nput: Granular,short rod and spherical solids with <20% moisture

Output: Granules,short rods and spheres with 3%-5% moisture

Temperature: Inlet air temperature <100°C

Additional Feature: Cooling

Application: Used in industries such as food processing, pharmaceuticals, chemicals and agriculture, it can efficiently and evenly dry a variety of materials such as powders, granules and particles.

Commitment: promise of the spiral vibrating dryer is to provide industries with reliable, efficient and uniform drying solutions.

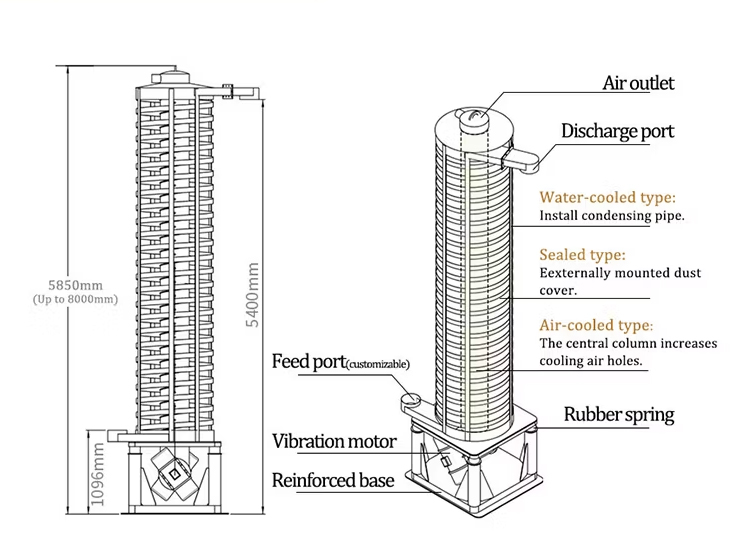

The Spiral Vibrating Dryer uses a fan to dry and cool the material through the holes on the center column. It is suitable for cooling and drying high-temperature materials in modified plastic production lines. Vibrating conveyors with a conveying capacity of 500-4000kg/h are available.

The Spiral Vibrating Dryer is a standard equipment for lifting bulk materials in many industries. It can convey, dry and cool plastic granules, rubber granules, chemical and pharmaceutical intermediates, metal salts, solder powder, glass ingredients, catalysts, abrasives and ash as well as milk powder, coffee powder, tea, nuts, nutritional products and grains.

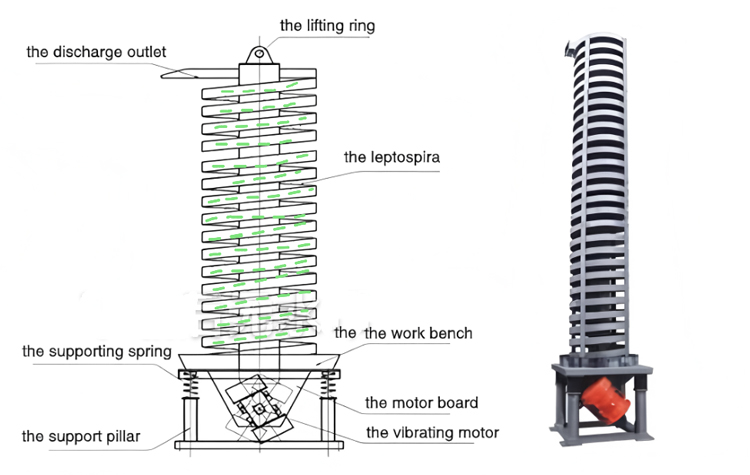

Spiral vertical vibration dryer is a common drying equipment, and its structure mainly includes the following components:

Main frame: Provides a frame structure to support and fix the entire equipment to ensure the stability and safety of the equipment.

Vibration motor: Provides vibration power for the entire equipment, and can control the movement of materials in the drying cylinder by adjusting the vibration frequency and amplitude.

Screw: Used to carry the material to rotate upward and convey, in a spiral shape.

Drying cavity: The main working area of the equipment, used to place the material to be dried.

Discharge port: Used to discharge the dried material, discharged from the upper discharge port.

The working principle of the spiral vibrating dryer is to combine spiral motion and vibration to promote the drying process. The equipment consists of a spiral conveying system in the drying chamber. As the material passes through the spiral conveyor, it is subjected to controlled vibration, which helps to effectively remove moisture. The spiral motion ensures uniform heating, while the vibration helps to enhance heat transfer and drying efficiency.

Spiral Conveyor System: The spiral design allows the material to move continuously, ensuring uniform drying.

Vibration Mechanism: Controlled vibration helps enhance heat transfer and dehumidification.

Adjustable Parameters: Dryers typically offer adjustable vibration intensity, temperature, and drying time to precisely control the drying process.

Heat Distribution: The spiral design facilitates even heat distribution for consistent drying.

Uniform Drying: The spiral motion and vibration combined ensure uniform drying and prevent uneven moisture content in the material.

Fast Drying: The efficient heat transfer mechanism in the spiral vibrating dryer reduces drying time.

Gentle Handling: The controlled vibration and spiral motion prevent material degradation, making it suitable for delicate or heat-sensitive materials.

Continuous Operation: The continuous movement of the material through the screw conveyor allows for an uninterrupted drying process.

Customizable: The spiral vibrating dryer can be customized to specific drying requirements and material properties.

Food Industry: Drying of food powders, grains, and snacks.

Pharmaceutical Industry: Drying of pharmaceutical powders and granules.

Chemical Industry: Drying of chemical powders, pigments, and granular materials.

Agricultural Industry: Drying of fertilizers, seeds and agricultural products.

Other Industries: Drying of plastics, minerals and industrial materials.

Vibratory Spiral Dryers are valuable assets in industrial drying processes, efficiently and evenly drying a wide range of materials. With a unique combination of spiral motion, controlled vibration and customizable features, Vibratory Spiral Dryers are a versatile solution for industries seeking high-quality, efficient drying solutions.

| Model | Φ | Φ1 | Φ2 | H | H1 | H2 | H3 | D | Lx8 | Ld×Bd | Φd |

| DZC300 | 300 | 146 | 500 | ~2000 | ~2750 | 40 | 75 | 270 | 680×680 | \ | 11 |

| DZC500y | 500 | 219 | 850 | ~3000 | ~4020 | 50 | 80 | 475 | 1080×1080 | 880×880 | 13 |

| 550 | 245 | 900 | ~35000 | ~3000 | ~4530 | 55 | 85 | 500 | 1100×1100 | 900×900 | 13 |

| DZC600 | 600 | 273 | 9500 | ~4000 | ~5150 | 60 | 85 | 525 | 1100×1100 | 900×900 | 15 |

| DZC800 | 800 | 351 | 1200 | ~4500 | ~5650 | 60 | 90 | 650 | 1300×1300 | 1050×1050 | 150 |

| DZC850 | 850 | 402 | 1250 | ~5000 | ~6150 | 65 | 100 | 675 | 1400×14000 | 1150×1150 | 17 |

| DZC90 | 900 | 530 | 1300 | ~6000 | ~7180 | 65 | 110 | 700 | 1600×1600 | 1300×1300 | 17 |

The spiral vibration dryer complies with the IOS standard. It can customize the appropriate spiral vibration dryer according to your material characteristics and conveying height. We provide timely after-sales service and technical support to ensure that customers can get timely help and solutions when they encounter problems during use. If you have any needs, please feel free to contact us!

Address:China,Yanjin county forest park gate to the west 1000 meters north road.