Cinnamon powder ultrasonic vibration sieve is a high-efficiency and precision screening equipment specially used for sieving cinnamon powder. This equipment combines traditional vibration sieve and ultrasonic technology, which can effectively solve the problems of mesh blockage, low screening efficiency and low precision in the ordinary vibration screening process due to the high fineness, easy agglomeration, light weight and possible static electricity of cinnamon powder. It is suitable for fine powder, ultrafine powder or materials that are easy to block the net.

Cinnamon powder ultrasonic vibration sieve is a device specially used for screening cinnamon powder. It uses ultrasonic technology combined with vibration sieve to achieve efficient and accurate grading and screening of cinnamon powder.

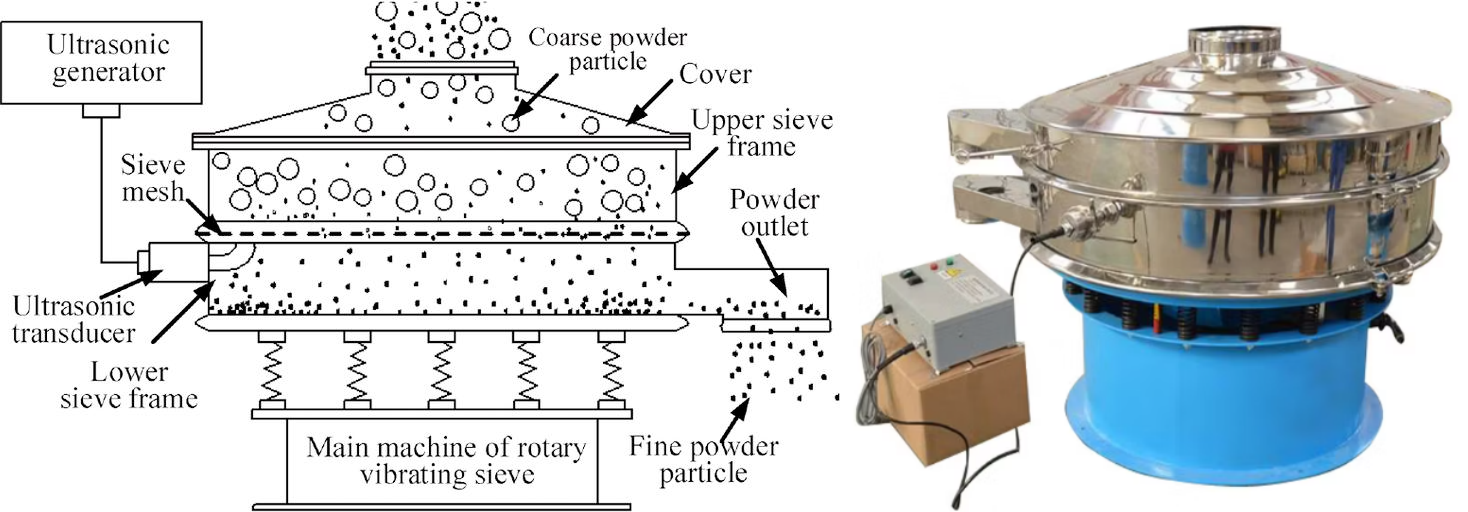

Ultrasonic transducers can convert electrical energy into high-frequency mechanical vibrations.

When screening cinnamon powder, high-frequency vibration can effectively overcome the agglomeration, adsorption and clogging problems caused by factors such as fine particles and surface characteristics of cinnamon powder, allowing cinnamon powder to be quickly and evenly dispersed and flowed on the sieve.

The equipment can accurately classify according to different particle sizes.

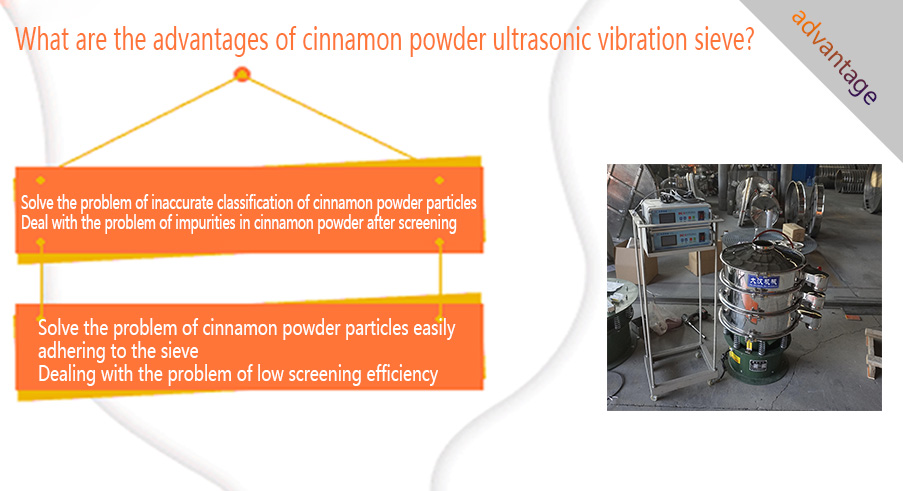

Solve the problem of inaccurate classification of cinnamon powder particles

The agglomeration of cinnamon powder particles causes a mixture of sizes, and ordinary screening is difficult to completely separate ultrafine particles from medium particles. The cinnamon powder ultrasonic vibration sieve adopts a multi-layer sieve configuration to achieve fine classification.

Deal with the problem of impurities in cinnamon powder after screening

After the cinnamon powder particles agglomerate, they are attached to the corners or frame of the sieve, and the powder is electrostatically adsorbed on the sieve and cannot be removed. The ultrasonic system can clean the residual powder on the sieve and reduce the time for manual cleaning.

Solve the problem of cinnamon powder particles easily adhering to the sieve

Cinnamon powder has a certain amount of natural oil, high powder fineness, small particles, and is easy to agglomerate under conditions of slightly high humidity or unventilated environment. High-frequency ultrasonic vibration on the surface of the sieve can break the adhesion between the powder and the sieve.

Dealing with the problem of low screening efficiency

Traditional vibrating sieves have slow screening speeds when processing ultrafine powders, poor powder fluidity, and are easy to accumulate on the sieve. Ultrasonic vibration can increase the dispersion of materials on the sieve, make the particle distribution more uniform, and reduce accumulation.

The mesh number selection of cinnamon powder ultrasonic vibrating sieve should be determined according to the purpose, particle size requirements and processing technology of cinnamon powder. Cinnamon powder, as a food seasoning, Chinese medicinal material or additive, usually requires a fine and uniform particle size. Generally speaking, the mesh number range of common cinnamon powder on the market is approximately between 80 mesh and 400 mesh.

80-120 mesh: suitable for coarse-grained cinnamon powder, often used in baking, seasoning or food processing that requires a certain granularity. This mesh number has high screening efficiency and is suitable for large-scale production.

120-200 mesh: suitable for medium-fine cinnamon powder, widely used in food additives, beverage ingredients or traditional Chinese medicine powder, taking into account both fineness and fluidity.

200-400 mesh: suitable for ultra-fine cinnamon powder, used in high-end foods (such as chocolate, coffee flavoring), cosmetics or fine traditional Chinese medicine preparations, high-precision screening is required to ensure uniformity.

Cinnamon powder ultrasonic vibrating sieve is mainly used in industries with high requirements for the purity, fineness and uniformity of cinnamon powder. Its core value lies in improving production efficiency and ensuring product quality.

Fine sieveing of spice powder

After grinding the dry cinnamon, in order to ensure the taste of the spice, the cinnamon powder can be sieveed through the cinnamon powder ultrasonic vibrating sieve to remove large particles and impurities and ensure uniform particle size. Cinnamon powder is slightly oily and easy to clump after grinding; ultrasonic vibration effectively breaks up lumps and improves fluidity.

Pretreatment of raw materials for Chinese herbal medicine slices and pills

In the production of Chinese herbal pills, granules or extract powders, cinnamon powder is often used as a raw material or auxiliary material, and needs to be processed through fine sieveing to meet the requirements of the pharmacopoeia for powder fineness. Medicinal powders have high requirements for purity and particle size distribution. Ultrasonic sieveing can prevent impurities from mixing in and improve drug safety.

Pretreatment of natural spice powder sieveing and essential oil extraction

As a natural spice ingredient, cinnamon powder is used to make scented candles, essential oil diffusers, handmade soaps, etc. Before use, it must be ensured that the powder particle size is fine and uniform. Ultrafine powder is required, and traditional sieves are prone to sticky powder and blockage; ultrasonic vibrating sieves can ensure continuous and efficient sieveing.

Standardized processing of cinnamon powder for export

Cinnamon powder ultrasonic vibrating sieves are used for export. Cinnamon powder has high quality standards, and the sieveing process must ensure that it does not contain coarse particles, fibers and foreign matter. Multi-stage sieveing improves purity, and cinnamon powder ultrasonic vibrating sieves can reduce manual intervention.

Cinnamon powder ultrasonic vibration sieve has important application value in food, medicine, chemical and other industries. It can improve product quality and reduce production costs. It is especially suitable for production scenarios with high requirements on powder fineness and purity.

Address:China,Yanjin county forest park gate to the west 1000 meters north road.