Daylily linear vibrating screen is a kind of equipment specially used for screening dried or fresh daylily. It uses the linear vibration generated by the synchronous reverse rotation of the dual vibrating motors to push the daylily to make a linear jumping motion on the screen surface. It can achieve grading, impurity removal or dehydration through multi-layer screens. It is particularly suitable for processing strip-shaped, wet and easily entangled materials such as daylily, and realizes functions such as grading, impurity removal, soil removal, and length sorting.

The working principle of daylily linear vibrating screen is based on the synergy of dual vibrating motors

Material movement: Daylily is thrown up and moves forward in a linear jumping motion on the screen surface under the action of the exciting force and its own gravity, and moves along the screen surface.

Screening process: The material is graded (separating daylilies of different sizes) or impurities (removing sand, stone, fiber, etc.) through screens with different apertures. Multi-layer screens can produce products of multiple specifications at the same time, which are discharged from different outlets.

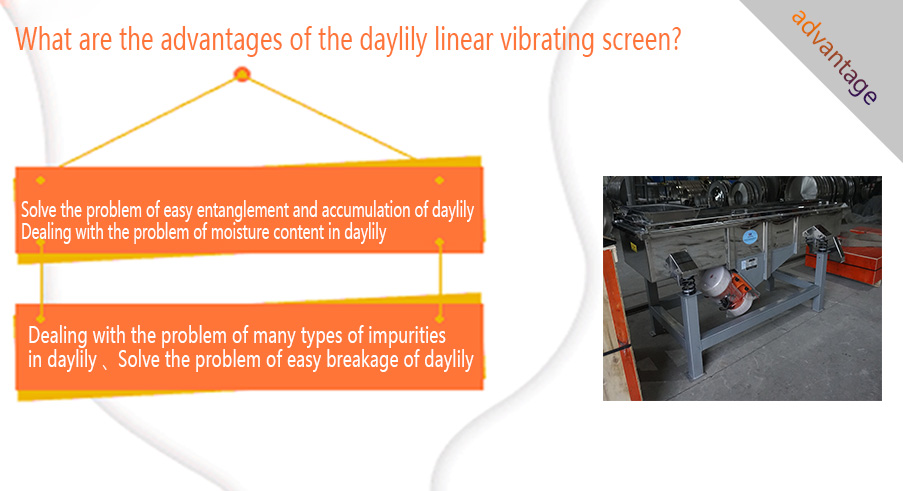

Solve the problem of easy entanglement and accumulation of daylily

The forced linear motion of the linear vibrating screen helps the daylily to form a more uniform material layer on the screen surface, reducing the possibility of mutual entanglement and accumulation. Linear motion is more conducive to the forward conveying and dispersion of long strips or irregularly shaped materials, reducing the chance of agglomeration.

Dealing with the problem of moisture content in daylily

Linear vibrating screens can usually be designed with a larger screen surface inclination angle, using gravity to assist the rapid movement of materials, reducing the residence time on the screen surface, thereby reducing the risk of adhesion and blockage. Many daylily linear vibrating screens are equipped with net cleaning devices such as bouncing balls or rotating brushes.

Dealing with the problem of many types of impurities in daylily

Daylily may be mixed with various impurities such as soil, stones, and broken leaves. These impurities vary in shape, size and density, making screening difficult. Daylily linear vibrating screen can achieve multi-stage screening through the design of multi-layer screens, and screen out impurities of different sizes separately.

Solve the problem of easy breakage of daylily

Daylily is relatively brittle and easy to break during screening. The linear vibrating screen reduces the crushing rate by reasonably designing the vibration parameters and the screen surface structure, so that the screen can not only effectively screen the daylily, but also play a certain buffering role on the material and protect the integrity of the daylily.

The screening mesh number of daylily should be determined according to its processing purpose and form (fresh vegetables, dried vegetables or dehydrated vegetables).

Coarse screen: 4-10 mesh

It is suitable for removing large impurities (such as branches and leaves, mud blocks) or preliminary classification (such as distinguishing length) in daylily. 4-6 mesh is suitable for fresh vegetables or wet vegetables, and 8-10 mesh is suitable for the initial screening of dried vegetables.

Medium screen: 10-20 mesh

It is suitable for grading dried daylily, separating vegetable strips of different lengths or thicknesses to meet the needs of packaging or deep processing. 12-16 mesh is a common choice, balancing efficiency and precision.

Fine screen: 20-40 mesh

It is used for dehydrated daylily or high-quality products (such as export grade) to remove fine impurities or screen uniform thin strips. 30-40 mesh is suitable for ultra-fine screening, but be aware of the risk of clogging.

|

Grading layers |

Screen mesh(mm opening) |

Functional description |

|

First layer |

12~15mm |

Remove long stems, miscellaneous branches and other long objects |

|

Second layer |

6~10mm |

Separate high-quality strip daylily |

|

Third layer |

2~5mm |

Separate broken vegetables, short stems and powder |

Large daylily planting base or primary processing plant: Use multiple large daylily linear vibrating screens to quickly remove impurities and preliminarily grade fresh daylily, providing processing capacity for subsequent large-scale cleaning and drying.

Dried daylily processing plant: Use multi-layer linear vibrating screens to perform multi-level sorting of dried daylily, and carry out refined grading and packaging according to market demand.

Food processing enterprises: Apply daylily linear vibrating screens to the production line of daylily powder to remove impurities in raw materials, ensure the fineness and purity of powder, and use it for the production of pastries, fillings, etc.

Daylily is an agricultural product with high economic value, widely used in food, export and medicine and food fields. Daylily linear vibrating screen is one of the most common and practical screening equipment, especially suitable for strip-shaped, fragile and impurity-rich materials such as daylily.

Address:China,Yanjin county forest park gate to the west 1000 meters north road.