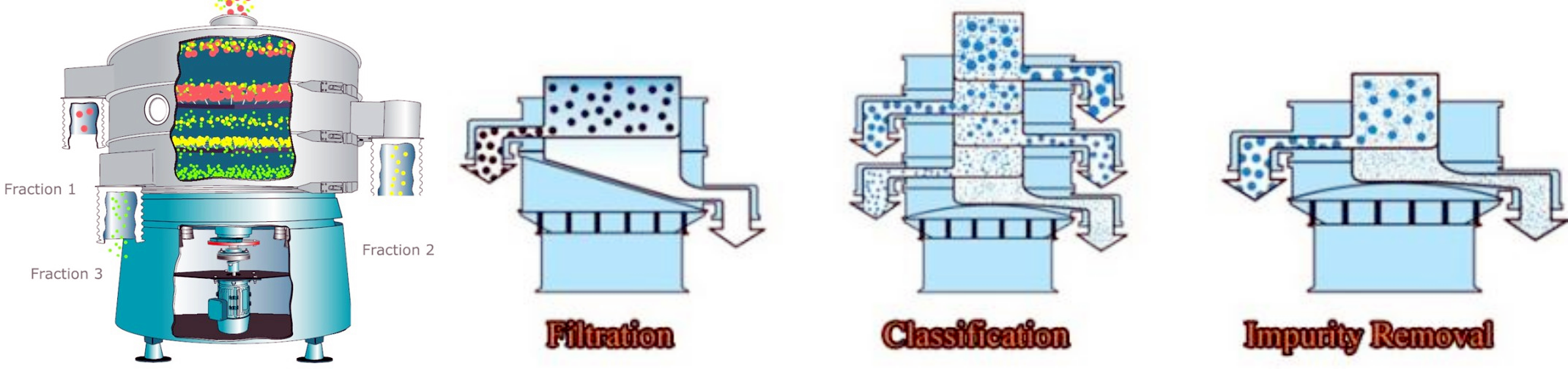

Quinoa vibrating screen is a screening device specially used for quinoa processing. It mainly uses the vibration principle to achieve the removal and classification of quinoa (particle size is usually 0.5-2mm, density is about 0.7g/cm3). Vibration is used to classify quinoa by size, greatly improving (such as broken shells, dust, stones) or separating different specifications of screening. It is widely used in quinoa processing, such as partitioning, grading, and selection.

Quinoa vibrating screen is a vibrating screening equipment used to clean and grade quinoa grains. It is widely used in grain processing, agricultural seed processing, healthy food production and other fields.

Particle size separation: quinoa is graded according to particle size (such as whole grains, broken grains, and powder).

Impurity removal: Quinoa vibrating screen can remove foreign matter such as sand, straw, and empty shells.

Surface cleaning: Vibration friction removes epidermal saponins (reduces bitterness)

Quinoa vibrating screen uses the cyclic vibration generated by the vibrating motor or eccentric block to grade the quinoa particles in the sieve holes according to particle size and weight and separate them through the sieve holes.

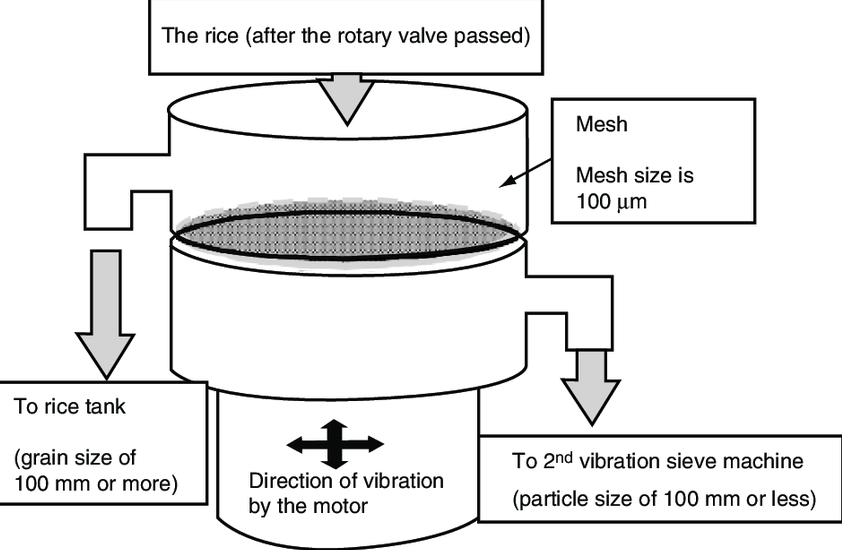

Quinoa enters the sieve body from the feed port

Under the action of vibration, quinoa particles smaller than the sieve hole size pass through the sieve and fall to the lower layer, while particles larger than the sieve hole size remain on the upper layer of the sieve, thereby achieving graded screening.

During the vibration process, impurities in quinoa such as stones and soil blocks will also be separated from quinoa due to vibration and discharged from the sieve body.

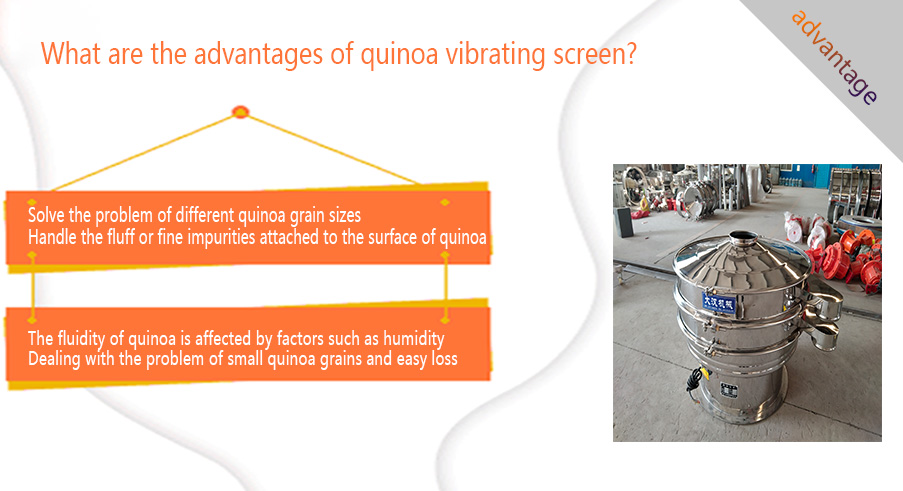

Solve the problem of different quinoa grain sizes

Different varieties and different growing batches of quinoa have different grain sizes, roundness, flatness, etc., which makes it difficult to achieve accurate separation with a single aperture screen. Quinoa vibrating screens usually use a multi-layer screen structure to achieve multi-level sorting and effectively separate quinoa grains of different specifications.

Handle the fluff or fine impurities attached to the surface of quinoa

The surface of quinoa may have fine fluff or be contaminated with fine soil, dust, etc. during harvesting and transportation, which can easily clog the screen. The high-frequency vibration generated by the quinoa vibrating screen can effectively shake off the fluff and fine impurities attached to the surface of quinoa, improving the screening efficiency.

The fluidity of quinoa is affected by factors such as humidity

The fluidity of quinoa is affected by factors such as its moisture content. Excessive humidity may cause grains to stick together, affecting the screening efficiency. A larger vibration intensity helps to disperse the sticking quinoa grains and improve their fluidity on the screen surface, or properly dry the quinoa with too high humidity before screening.

Dealing with the problem of small quinoa grains and easy loss

Quinoa grains are relatively small. If the vibration frequency and amplitude are not set properly, some qualified quinoa grains may be discharged along with impurities, causing losses. Quinoa vibrating screen can optimize the movement trajectory and residence time of the material on the screen surface, reducing the loss of qualified grains.

Large-grain quinoa: The mesh number of the screen can be selected from 10 mesh to 16 mesh, and the mesh size is 2.00mm-1.18mm, which can screen out larger quinoa particles.

Medium-grain quinoa: The mesh number is more suitable between 16 mesh and 25 mesh, and the mesh size is 1.18mm-0.710mm, which can screen out medium-sized quinoa particles.

Small-grain quinoa: For small-grain quinoa, 25 mesh to 40 mesh screens are more suitable, and the mesh size is 0.710mm-0.425mm.

Quinoa vibrating screen is widely used in all aspects of quinoa processing to ensure the quality and purity of the final product.

Quinoa pre-cleaning (grain): After quinoa is harvested from the farm, it contains stones, construction, construction, etc., and needs to be pre-cleaned before storage. Quinoa vibrating screen adopts a double-layer sieve hole (the upper sieve hole is 3mm to remove large impurities, and the lower layer is 1mm to remove fine impurities), equipped with a suction device, and has a production capacity of 10-50t/h.

Primary processing of quinoa: During the initial processing of quinoa after harvest, it needs to be graded into different specifications. Quinoa vibrating screen (sieve hole 2mm, 1mm, 0.5mm) is used to remove impurities in quinoa, such as soil, sand, straw, etc., to improve the purity of quinoa.

Seed selection: Quinoa for breeding or export requires high purity, and seeds with uniform particle size (1-1.5mm) are screened to reduce sunken grains and foreign matter. Quinoa vibrating screen can use three layers of screens (1.5 mm, 1.2 mm, 0.8 mm mesh), with end sorting, and a capacity of 1-5t/h.

Quinoa grading: Quinoa is graded according to the size of the particles to meet different market needs and processing requirements. For example, large particles of quinoa can be used for direct cooking or making high-end products, and small particles of quinoa can be used to process quinoa powder, etc.

Quinoa vibrating screen is one of the indispensable key equipment in the quinoa processing process. Through its efficient screening ability, it can effectively remove impurities and grade, thereby ensuring the quality of quinoa products and meeting different processing requirements.

Address:China,Yanjin county forest park gate to the west 1000 meters north road.