Vibro Sifter for Rapeseed Sorting separates and grades rapeseed by particle size, removing impurities such as dirt, stems, and seeds. It can screen rapeseed with mesh sizes ranging from 6 to 30 to remove unwanted impurities or classify them into different grades. It has a processing capacity of 500-800 kg per hour. Qualified kernels are discharged from the middle collection port, while dirt and broken particles are thoroughly separated by the bottom screen. The entire process maintains a screening accuracy exceeding 99% while operating continuously.

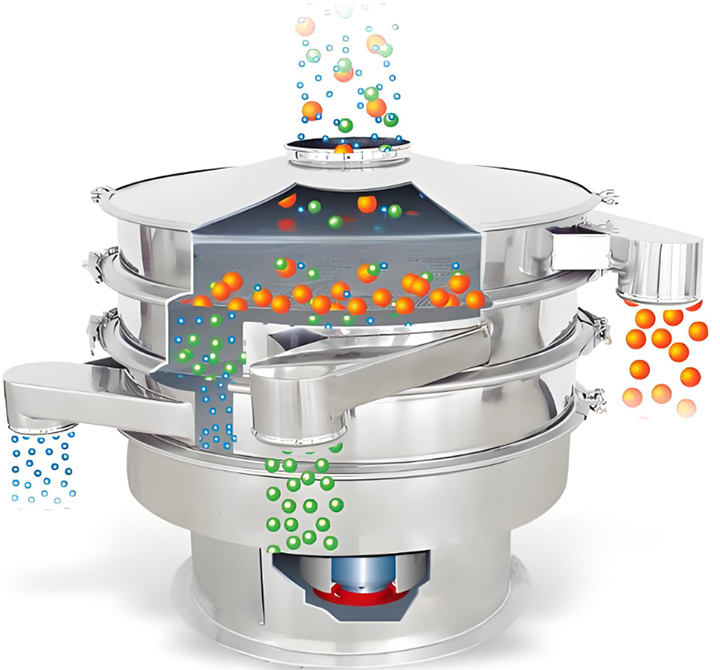

The key to the vibrating screen's precise rapeseed grading and efficient impurity removal lies in its three-dimensional gyratory vibration effect generated by a vertical vibrating motor. This equipment utilizes multiple layers of precision screens to create a rigorous particle size separation channel. The upper, large-aperture screen acts as a primary screening barrier, separating the main rapeseed from fine impurities in a bouncing motion. This process also traps stems and large impurities on the screen surface and directs them to the discharge port. The middle, core screen features a mesh size matching the standard rapeseed particle size. Through a continuous, three-dimensional spreading motion, qualified seeds are screened and diverted in a controlled manner, while oversized, unsuitable seeds are effectively retained. The bottom, fine-grained screen performs the ultimate filtration function, ensuring the complete separation of fine dust and broken seeds. This hierarchical screening mechanism, based on strict physical standards and coupled with a bouncing ball system to continuously clean the screen apertures, enables simultaneous multi-stage purification and precise grading of rapeseed within a fully enclosed system, ultimately improving both impurity removal and product purity.

The sieving effect of Vibro sifter For rapeseed sorting has a great influence on the performance of later seeds. Let us explain in detail the two types of sieving.

1. Coarse screening process

The seeds before the coarse sieving contain many impurities, and there are some impurities with larger particles, such as stones, hemp flakes, straw, plastic flakes, etc. In the process of coarse screening, the Vibro sifter screen is mainly used to remove impurities for the first time on the seed material.

2. After the coarse sieving process

Screen some fine impurities in the seeds. This process is relatively fine and requires a larger mesh screen to make the sieved seeds cleaner. The seeds after fine sieving generally have a higher emergence rate and later yield, and the fine sieved seeds can also be weighed and packaged.

During the rapeseed sorting process, the Vibro Sifter for Rapeseed Sorting tosses the rapeseed and simultaneously disperses it in a complex horizontal, vertical, and inclined trajectory, effectively loosening the material and increasing its contact with the screens. Large impurities such as stems, larger than the top screen aperture, are transported radially along the screen surface to the discharge outlet due to the bouncing action. The main rapeseed and fine impurities quickly penetrate the upper screen and fall onto the lower screen. In the lower screen area, rapeseed that meets the specifications due to its larger particle size is retained and guided by the vibration force to the middle discharge outlet for collection. Meanwhile, smaller dust, broken particles, and light impurities penetrate the bottom screen and fall into the collection hopper, achieving complete separation.

The Vibro Sifter for Rapeseed Sorting is equipped with a bouncing ball cleaning system and brushes during the rapeseed sorting process, effectively preventing rapeseed from clogging the screen apertures. At the same time, the rotating nylon brush, designed for working conditions prone to adhesion, effectively removes fine powder and light impurities that adhere to the screen surface due to moisture or static electricity through continuous contact cleaning. This allows the screen to maintain a smooth opening rate throughout the entire operation cycle, ensuring stable material flow and consistent grading accuracy during the screening process, thereby significantly improving the continuous production capacity of rapeseed impurity removal and grading operations and the purity of the final product.

| Model |

Diameter (mm) |

Feeding Size (mm) |

Frequency (RPM) |

Layers |

Power (kw) |

Capacity (kg/h) |

| DH-400 | 400 | <10 | <1500 | 1-5 | 0.18 | 100 |

| DH-600 | 600 | 0.25 | 200 | |||

| DH-800 | 800 | 0.55 | 500 | |||

| DH-1000 | 1000 | 0.75 | 800 | |||

| DH-1200 | 1200 | 1.1 | 1200 | |||

| DH-1500 | 1500 | 1.5 | 1800 | |||

| DH-1800 | 1800 | 2.2 | 2000 |

Vibro Sifter for Rapeseed Sorting is a specialized screening machine designed to efficiently separate and grade rapeseed based on size and quality. Rapeseed, a key crop for oil production and animal feed, requires precise sorting to remove impurities, broken seeds, and foreign materials. The Vibro Sifter uses high-frequency vibrations to move rapeseed across a screen mesh, ensuring accurate separation. Its durable stainless steel construction and customizable mesh sizes make it suitable for various rapeseed processing needs. The dust-proof design minimizes particle emissions, while the adjustable vibration settings optimize sorting efficiency.

Address:China,Yanjin county forest park gate to the west 1000 meters north road.