The gypsum powder screening machine can screen slightly abrasive gypsum powder. It can be equipped with a single screen to remove impurities, or 2-5 screens to grade the powder, depending on the intended use. The equipment can screen approximately 20 kg to 10 tons of gypsum powder per hour. Larger screens result in a larger screening area; screens of 400mm, 600mm, 1000mm, and 1200mm are available. Two common types of screens are available: rotary vibrating screens and linear vibrating screens. The following is a detailed introduction to the gypsum powder screening machine.

Gypsum powder is fed into the top screen of the gypsum powder screening machine through the inlet. The vibration motor drives the screen to vibrate, causing smaller particles to pass through the screen openings and fall to the bottom, exiting from the lower outlet. Larger impurities and particles, being larger than the screen openings, are blocked on the screen and exit from the upper outlet, thus completing the gypsum powder screening process.

The gypsum powder screening machine offers advantages such as particle size control, grading of gypsum powder, removal of unwanted impurities, and product uniformity.

Fineer gypsum powder particles react faster with water, resulting in faster setting. Screening removes excessively coarse or fine particles, stabilizing the setting time within the required process range.

Using the gypsum powder screening machine, workers can separate gypsum powder into different specifications such as 80 mesh, 120 mesh, and 200 mesh. Coarse powder can be used for gypsum board core material, fine powder for plastering gypsum, and ultrafine powder for medical gypsum, etc. This allows different particle sizes of gypsum powder to be used effectively, reducing waste.

Sieving gypsum powder ensures both strength and fineness, resulting in uniform and smooth particles. This prevents construction defects or blockages in conveying pipes caused by uneven particle size, leading to better quality gypsum powder products.

gypsum powder screening machines come in two types: rotary vibrating screens and linear vibrating screens. For high-volume gypsum powder production, choose a linear vibrating screen; for finer particle sizes, choose a rotary vibrating screen.

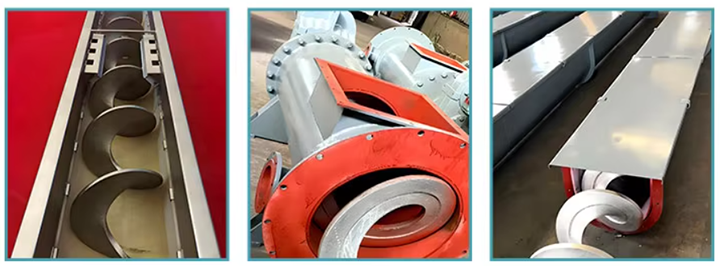

The rotary vibrating screen resembles an upright cylinder. It can screen light, fine, and easily agglomerated gypsum powder, with mesh sizes ranging from 20 to 500 mesh. To obtain gypsum powder of different particle sizes in a single pass, 1-5 layers of screens can be installed. Installing one screen can yield gypsum powder of two particle sizes, while installing two screens can yield gypsum powder of three particle sizes. The number of screen layers depends on the actual needs. The output of a rotary vibrating screen ranges from 100 kg to 3300 kg per hour.

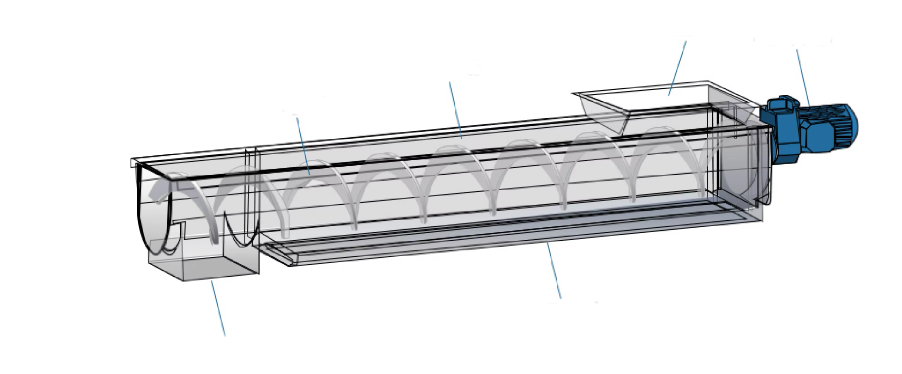

Gypsum is prone to absorbing moisture and clumping. When screening clumped gypsum powder, a linear vibrating screen can be used. A linear vibrating screen resembles a flat rectangular prism. Its output is higher than that of a rotary vibrating screen, typically ranging from 10 kg to 10 tons per hour. The screening precision is lower than that of a rotary vibrating screen; the mesh size of a linear vibrating screen is between 10 mesh and 400 mesh. A linear vibrating screen is suitable for rapid impurity removal from gypsum powder or for continuous batch screening of gypsum powder.

The price of a gypsum powder screening machine is approximately $900-$4500. For example, a double-layer rotary vibrating screen with a screen diameter of Φ600mm costs around $1200-$4000, while a stainless steel linear vibrating screen with three screen layers costs around $5000-$7000. The price of a screening machine depends on factors such as screen size, the number of screen layers, and the material of the equipment. Stainless steel screening machines are more expensive than carbon steel ones, and the more screen layers installed, the higher the price.

gypsum powder screening machines can be used after grinding raw materials into gypsum powder. At this stage, the gypsum powder may contain some coarse particles that haven't been ground finely, as well as iron filings and other impurities from mill wear. The gypsum powder screening machine screens these coarse particles or impurities, allowing them to be returned to the grinding mill for further grinding. It can also be used after raw material crushing to separate the crushed gypsum stone according to particle size, or to remove light impurities such as soil and weeds, resulting in more uniform calcination.

gypsum powder screening machines can screen different types of gypsum powder, including medical gypsum, high-end mold gypsum, artistic gypsum, and ultrafine powder. As a mechanical device, it only requires a switch to operate, reducing the time and labor required for manual screening. Furthermore, it offers a choice between fine-screen rotary vibrating screens and high-capacity linear vibrating screens, providing diverse solutions for gypsum powder screening.

Address:China,Yanjin county forest park gate to the west 1000 meters north road.