Screw conveyor for metal scrap is primarily used to transport hard, sharp-edged, and easily abraded metal scrap. Its core features high-chromium alloy spiral blades, thickened wear-resistant conveying pipes, and a high-strength drive system, fundamentally solving the problems of wear, jamming, and poor impact resistance inherent in conventional equipment. It boasts core advantages such as wear resistance, impact resistance, and anti-clogging capabilities. It can flexibly achieve multi-angle conveying and supports full-dimensional non-standard customization. Roller equipment can be flexibly added to improve mobility according to the user's site layout and scrap characteristics. The position, shape, and quantity of inlet and outlet can be customized to match individual operational needs, significantly improving scrap transfer efficiency and reducing labor and equipment maintenance costs.

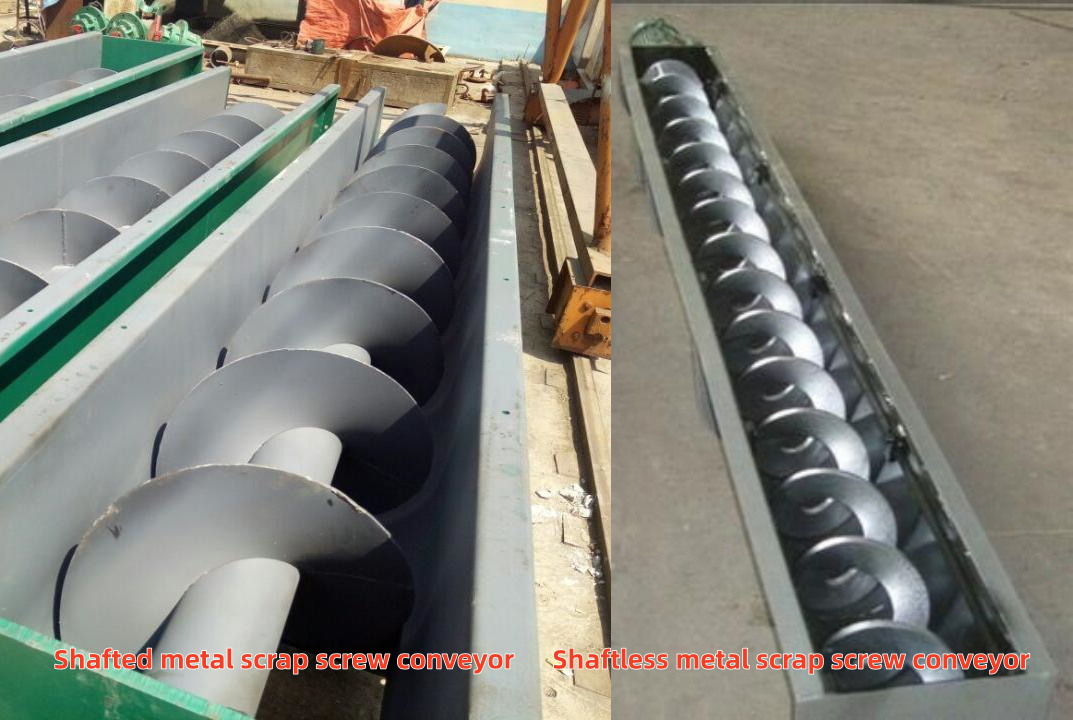

Based on customer conveying needs, we mainly produce two types of screw conveyors for metal scrap, both of which support full-dimensional non-standard customization. We can customize production according to the user's site layout and scrap characteristics to precisely match individual operational needs.

Shafted Screw Conveyor for Metal Scrap: Equipped with a solid drive shaft and high-chromium alloy spiral blades, it boasts strong structural rigidity and excellent impact resistance, specifically designed for high-hardness, heavy blocky metal scraps such as rebar ends, iron blocks, and hardware scraps.

Shaftless Screw Conveyor for Metal Scrap: Eliminates the central drive shaft, employing an integrated wear-resistant spiral blade design, fundamentally solving the problem of jamming easily entangled scraps such as metal wire, aluminum shavings, and copper shavings. The U-shaped open casing facilitates quick cleaning of residual scrap, reducing maintenance frequency and costs, and is particularly suitable for handling finely shaped, easily clump-forming metal scraps.

Designed for highly abrasive materials such as steel and aluminum shavings, the screw conveyor for metal scrap utilizes a shaftless spiral and wear-resistant liner structure, completely solving the problem of entanglement and jamming. The fully enclosed conveying system eliminates oil and debris splashing, enabling continuous automated recycling.

Wear-resistant design: Utilizing high-chromium alloy spiral blades and thickened conveying pipes, it easily handles the high hardness and sharp edges of metal scrap, reducing equipment wear at its source and extending service life.

Impact-resistant and anti-clogging: Equipped with a high-strength drive system, combined with an optimized blade and pipe structure, it can smoothly convey various forms of metal scrap, including granular, fragmented, and small lump materials, avoiding jamming and clogging.

Adaptable to diverse scenarios: Supports multi-angle conveying, requiring no complex site modifications, and widely adaptable to the waste transfer needs of various industries such as hardware processing, machinery manufacturing, and waste recycling.

Customizable: Rollers can be added to improve mobility according to site layout, and the position, shape, and number of inlet and outlet ports can be customized to perfectly suit the personalized operating scenarios of different users.

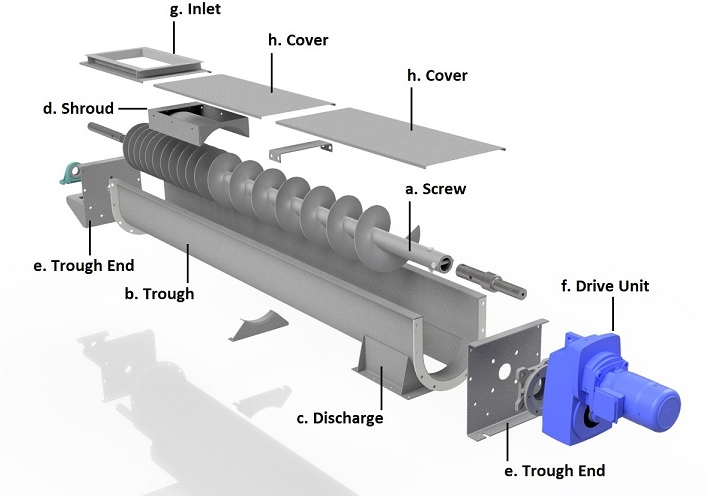

The core structure of the screw conveyor for metal scrap uses a spiral shaft structure combined with a reinforced tank with replaceable wear-resistant liners at the bottom, fundamentally preventing material entanglement and resisting extreme wear. The entire machine is driven by a heavy-duty geared motor, and all structural components are thickened and reinforced. Bearings are equipped with multiple seals to isolate metal dust. This design enables continuous, stable, and automated conveying of scrap materials such as steel and aluminum shavings, making it an indispensable and robust solution for the metal processing industry.

The Screw Conveyor for Metal Scrap operates on the core principle of rotating helical blades, adapting to the high density and hardness characteristics of metal scrap. After starting the equipment, the drive system drives the helical blades to rotate at a low and stable speed. The metal scrap fed into the inlet moves forward along the inner wall of the conveying pipe under the thrust of the blades and its own gravity, avoiding scrap splashing and equipment wear caused by high-speed operation. Finally, the scrap is accurately discharged through the outlet. The entire process is automated and adaptable to various metal scrap transfer needs.

The Screw Conveyor for Metal Scrap can handle three core forms of metal scrap: granular, powdery, and blocky, covering multiple recycling and processing scenarios across various industries.

Granular metal scrap: This type of scrap can transport various metal particles with a diameter of 0.1-10mm, including steel shot, copper granules, aluminum granules, stainless steel granules, and metal-rich particles generated during smelting. This type of scrap has good flowability and is suitable for stable conveying with shaft-driven conveyors.

Powdered metal scrap: This type includes dry, non-sticky powders such as iron powder, aluminum powder, copper powder, selenium powder, and telluride powder. A fully sealed conveying pipe and wear-resistant blade design prevent dust leakage and equipment wear, while also preventing powder agglomeration and blockage.

Blocking metal scrap: This type includes heavy, high-hardness steel rebar ends, iron blocks, hardware scraps, and scrap metal castings. The solid drive shaft and high-chromium alloy blades of shaft-driven conveyors provide strong load-bearing capacity and impact resistance, enabling stable conveying of larger pieces of scrap.

| Model |

Diameter (mm) |

Pitch (mm) |

Rotating speed (r/min) |

Capacity (m³/h) |

Rotating speed (r/min) |

Capacity (m³/h) |

Rotating speed (r/min) |

Capacity (m³/h) |

Rotating speed (r/min) |

Capacity (m³/h) |

|

| Small | 100 | 100 | 100 | 140 | 2.2 | 112 | 1.7 | 90 | 1.4 | 71 | 1.1 |

| 125 | 125 | 125 | 125 | 3.8 | 100 | 3 | 80 | 2.4 | 63 | 1.9 | |

| 160 | 160 | 160 | 112 | 7.1 | 90 | 5.7 | 71 | 4.5 | 56 | 3.6 | |

| 200 | 200 | 200 | 100 | 12.4 | 80 | 9.9 | 63 | 7.8 | 50 | 6.2 | |

| Small | 250 | 250 | 250 | 90 | 21.8 | 71 | 17.2 | 56 | 13.6 | 45 | 10.9 |

| 315 | 315 | 315 | 80 | 38.8 | 63 | 30.5 | 50 | 24.2 | 40 | 13.4 | |

| 400 | 400 | 355 | 71 | 62.5 | 56 | 49.3 | 45 | 38.6 | 36 | 31.7 | |

| Large | 500 | 500 | 400 | 63 | 97.7 | 50 | 77.6 | 40 | 62 | 32 | 49.6 |

| 630 | 630 | 450 | 50 | 138.5 | 40 | 110.8 | 32 | 88.6 | 25 | 69.3 | |

| 800 | 800 | 500 | 40 | 198.5 | 32 | 158.8 | 25 | 124.1 | 20 | 99.3 | |

The Screw Conveyor for Metal Scrap can achieve a full range of conveying angles from 0° to 90°. Horizontal conveying at 0° is the most efficient, suitable for long-distance transport of blocky and granular metal scrap. Inclined conveying from 30° to 60° requires large-pitch wear-resistant blades to prevent high-density scrap from sliding back, suitable for inter-floor transport in small to medium-sized processing plants. Vertical conveying at 90° requires a customized pressurized feeding device and anti-backflow structure. Relying on a high-power drive system, it can smoothly transport metal scraps and granules, perfectly solving the problem of vertical scrap lifting in space-constrained scenarios.

The Screw Conveyor for Metal Scrap can be flexibly integrated with various upstream and downstream equipment to build an automated, integrated metal scrap processing production line. At the front-end feeding stage, it can connect to the scrap outlet of metal processing machine tools, vibrating feeders, or belt conveyors to achieve automatic scrap receiving and conveying without manual loading. In the mid-stage transfer stage, it can work in conjunction with equipment such as magnetic separators and screening machines to complete the sorting and purification of metal scrap, accurately separating scrap of different materials such as iron filings and aluminum filings. At the back-end processing stage, it can be directly connected to metal crushers, briquetting machines, or scrap storage silos, sending the transferred scrap directly to the next processing step, forming a closed-loop operation of scrap generation – transfer – sorting – processing.

From large foundries to precision machining plants, our screw conveyor for metal scrap, with its heavy-duty shaftless design and customized wear-resistant solutions, has been successfully applied to the production lines of dozens of leading clients across various industries, effectively solving core pain points such as long chip entanglement, equipment wear, and workshop cleanliness.

Metal Screw Conveying in a Hardware Factory: Approximately 1.2 tons of easily entangled waste materials such as copper chips and wires are generated daily. Previously, manual cleaning and transfer were inefficient. Our customized shaftless metal scrap screw conveyor, featuring an integrated wear-resistant screw blade design, prevents copper wire entanglement and jamming at the source. Combined with a fully enclosed conveying pipe and dustproof inlet/outlet ports, it prevents dust leakage.

Material Recycling Plant: Focusing on the recycling and refining of titanium alloy scrap, loose titanium chips need to be transferred to a briquetting machine for compression molding. Previously, belt conveyors were used, resulting in high titanium scrap loss due to scattering. A new 20-ton/hour shafted screw conveyor for metal scrap is introduced, featuring high-chromium alloy screw blades and a solid drive shaft for enhanced impact resistance and wear resistance. A custom-designed 45° inclined conveying angle, coupled with large-pitch blades, prevents titanium scrap backflow. Precise docking of the inlet and outlet with the crusher and briquetting machine enables a closed-loop operation of crushing, conveying, and briquetting.

Aluminum ash slag treatment: Aluminum ash slag needs to be transferred from the unloading area to the harmless treatment workshop. A custom-designed fully enclosed heavy-duty screw conveyor for metal scrap is used. The conveying pipe is made of thickened anti-corrosion material to prevent corrosion from the aluminum ash slag. It is equipped with a pressurized feeding device and a sealed discharge valve to prevent the leakage of harmful gases and dust. A 90° vertical conveying design saves workshop space, and an intelligent monitoring system is installed to monitor the equipment's operating status in real time.

DaHan Machinery's screw conveyors for metal scrap are priced according to material, specifications, and customization needs, with basic models starting at $500, covering various operational scenarios. Basic models with or without shafts, suitable for small processing plants, are made of carbon steel and feature standard configurations, capable of handling small batches of metal scrap. Reinforced models for medium-sized enterprises, using high-chromium alloy wear-resistant materials and heavy-duty drive systems, are priced accordingly higher. Heavy-duty models customized for large recycling facilities combine large-diameter pipes, long-distance conveying, and automated linkage designs, and support customization options such as roller additions and inlet/outlet customization. While more expensive, these models are suitable for large-scale, heavy-duty operations, offering a balance of cost-effectiveness and practicality, allowing for flexible selection based on specific needs.

The core of the screw conveyor for metal scrap adopts high-chromium alloy spiral blades, thickened wear-resistant conveying pipes, and a high-strength drive system. It has the advantages of wear resistance, impact resistance, and anti-clogging. It can be adapted to the horizontal, inclined, or vertical conveying of various forms of metal scrap, such as granular, fragmented, and small blocks. It is widely used in industries such as hardware processing, machinery manufacturing, and waste recycling.

Address:China,Yanjin county forest park gate to the west 1000 meters north road.