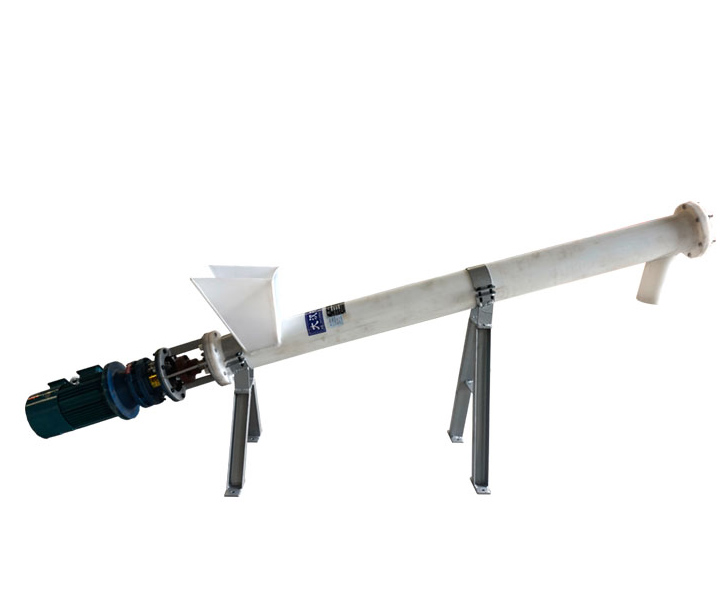

Corrosion-resistant, specially used in the transportation of strong acid and highly corrosive materials such as aquaculture industry

![]()

![]()

![]()

Price:$500.00-$20,000.00/Set

Consult now and enjoy a 10% discount

Conveying capacity: 142m³/h

Conveying length: 60 meters

Suitable temperature: -30~140℃

Applicable materials: chemical raw materials, fluorescent powder, poultry manure and other strong acid and strong alkaline materials

Application: chicken house, duck tongue, cattle farm, pig farm and other places that need to remove animal manure

Commitment:

Plastic screw conveyor is composed of polypropylene plastic helical blade and corrosion-resistant and non-deformable polypropylene tube. It is corrosion-resistant and can solve the problems of oxidation and corrosion after special materials contact with Q235 ordinary carbon steel and SUS304 stainless steel. It can be used in chicken farms , duck farms, pig farms, cattle farms, etc. are used to transport animal manure to replace manual cleaning, which can reduce labor intensity and improve the cleanliness of the farm space. Easy maintenance, long service life, can be customized according to customer site.

The plastic screw conveyor is specially used in the breeding industry, mainly used in chicken farms, duck farms, pig farms, cattle farms, etc. to process animal manure. The manure can be directly conveyed to the plastic screw conveyor through the manure cleaning conveyor belt. On the machine, it is transported to the manure pile by the conveyor. The whole process is fully automatic without manual participation and is faster and easier. Compared with the traditional metal conveyor, the cost is low and the efficiency is high, and the profit is more considerable. Common applications: chicken coops, duck tongues, cattle farms, pig farms and other places that need to remove animal manure

Plastic Screw Conveyor

For Conveying Poultry Manure

Plastic Screw Conveyor

For Chicken Manure

Resistant to strong acid and alkali corrosion

The plastic screw conveyors are all made of polypropylene materials (except the motor), which can prevent the materials from oxidative deterioration and prevent the machine from being corroded.

Sealing system

The sealing performance is good, which can prevent the odor from overflowing during the conveying process, and the feces are not easy to splash out, which improves the cleanliness of the farm space.

Large delivery volume

The conveying speed is fast, the manure is cleaned quickly, and the manure is cleaned. The conveying volume can reach 142 cubic meters per hour, and the conveying length of a single machine can reach 60 meters, which can reduce the labor intensity.

Flexible layout

It can be loaded and unloaded in the middle, the speed is high, the manure removal is fast, and the manure removal is clean.

1. Application: The plastic screw conveyor is resistant to strong acid and strong alkali corrosion. It is mainly used in the breeding industry, such as chicken coops, duck coops, etc., to transport poultry manure. It is also suitable for some chemical raw material industries that have corrosion requirements. It can transport Materials containing a certain amount of moisture; ordinary spiral carbon steel or stainless steel screw conveyors have a wider range of applications, and can be used in food, medicine, chemical, metallurgy and other industries that require hygiene.

2. Durability: The durability level of plastic screw conveyors is lower than that of ordinary screw conveyors. Although plastics are better than carbon steel and stainless steel in terms of corrosion resistance, alloy steel materials are less likely to deform and wear, and can be used for a long time , so the service life of the plastic screw conveyor is not as good as that of the ordinary screw conveyor.

| Model (FLS) |

100 | 120 | 140 | 160 | 200 | 250 | 300 | 400 |

| Spiral diameter (mm) |

88 | 108 | 140 | 163 | 187 | 240 | 290 | 360 |

| Housing tube diameter (Φmm) |

114 | 133 | 168 | 194 | 219 | 273 | 325 | 402 |

| Allowable working angle (α) |

0~60 | 0~60 | 0~60 | 0~60 | 0~60 | 0~60 | 0~60 | 0~60 |

| Conveying length (m) |

8 | 8 | 10 | 12 | 13 | 16 | 18 | 20 |

The motor reducer drives the rotation of the active drum, and then the active drum drives the conveyor belt to move the chicken manure on the conveyor belt to the plastic screw conveyor. The conveyor relies on the rotation of the screw shaft to drive the chicken manure forward, and then transports the manure outside the shed. pool or transport vehicle.

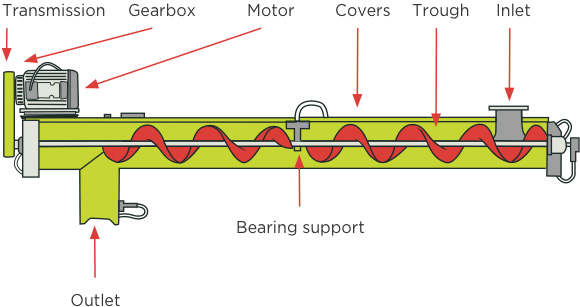

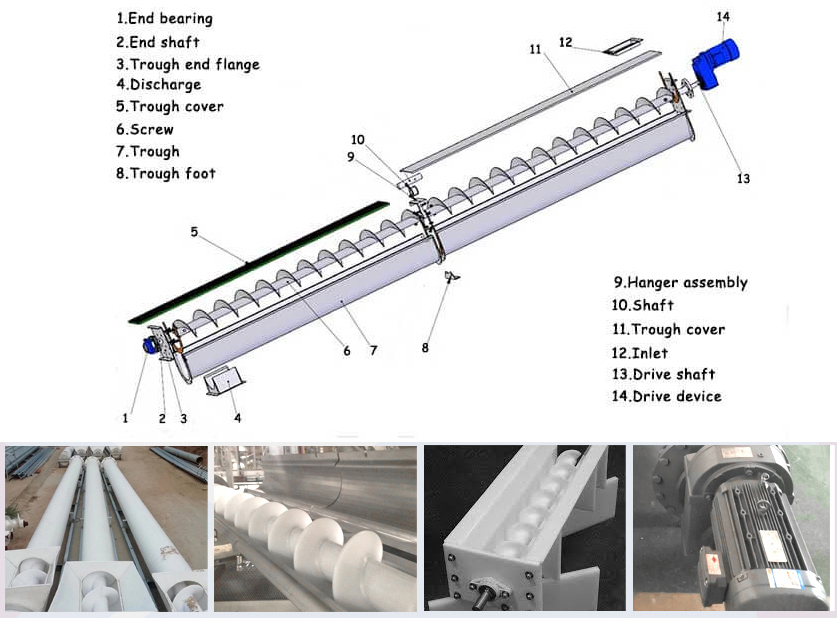

The plastic screw conveyor is mainly composed of a screw body, an inlet and outlet and a driving device.

The spiral body is composed of head bearing, tail bearing, suspension bearing, screw shaft and blade, casing, cover plate, base and so on.

Note: The drive device should be placed as far as possible on the discharge port end so that the screw shaft is in tension.

Conveying pig manure

Conveying capacity: 1 ton/hour

Conveying length: 3 meters

Feedback: Pig manure is very corrosive, and the acidic substances in pig manure will cause strong corrosion to structural steel. Here, it is recommended that the plastic screw conveyor be made of polypropylene PP material, which has good corrosion resistance, acid and alkali resistance, Oxidation resistance, so that the material will not deteriorate during the screening process.

Conveying chicken manure

Conveying capacity: 3 tons/h

Conveying length: 4 meters

Feedback: Corrosion-resistant and thickened blades can prevent damage caused by corrosion when transporting chicken manure, and solve the problem of easy oxidation and deterioration of materials in contact with metal. The manure can be automatically transported outside the shed or on a manure truck without going out of the shed.

The plastic screw conveyor produced by Xinxiang Dahan can be used in farms and chemical industries, avoiding the low efficiency of manual conveying. The manufacturer has obtained ISO and CE certification, the quality is guaranteed, and it can also be customized according to your requirements.

Address:China,Yanjin county forest park gate to the west 1000 meters north road.