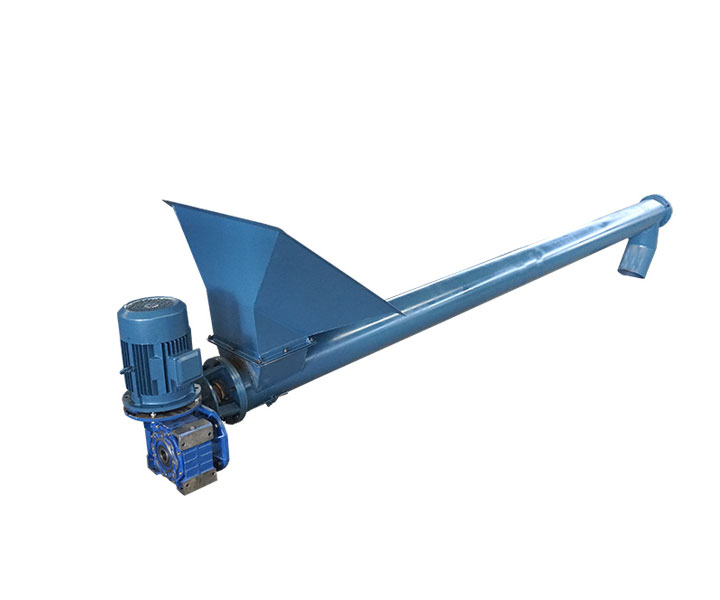

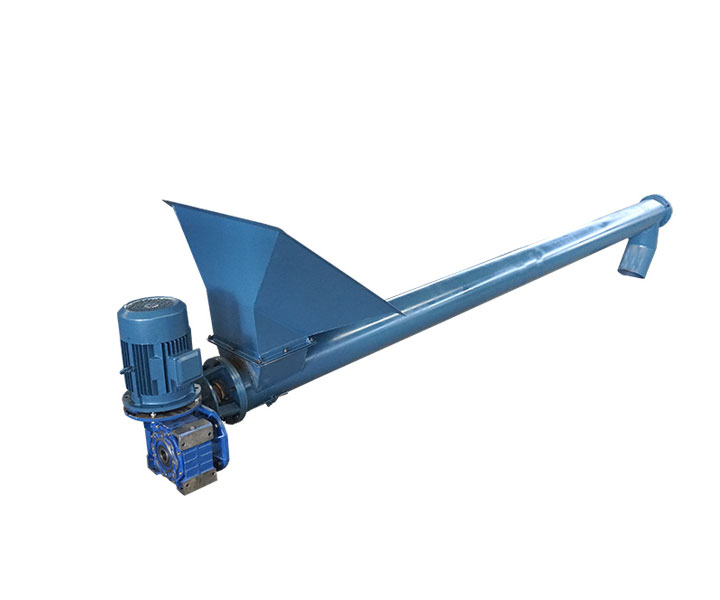

Horizontal, inclined, vertical conveying of powdery or granular materials

![]()

![]()

Price:$500.00 - $20,000.00/Set

Consult now and enjoy a 10% discount

Spiral diameter: 100-1250mm

Length: 2-70 meters

Delivery capacity: 143 cubic meters per hour

Speed: 20-112r/min

Pipe angle: General 45degree, 30degree, 60degree

Customization: installation angle (0-90 degrees), flange diameter size, import and export distance, size, etc. can be customized on demand

Applications: flour processing (bran, flour), feed (pet feed, pig feed), chemical industry (fertilizer granules, rubber powder), concrete production (fly ash, lime powder, sand, cement), etc.

Commitment:

Tubular screw conveyor is a kind of conveying equipment widely used in mining, chemical industry, feed, grain and oil, cement plant, commercial concrete and construction industry. It is suitable for horizontal conveying and tilting of loose materials such as powder, granular and small blocks. promote. Tubular screw conveyor has a screw diameter of 100-1250mm, fast speed, no jamming, no arching, and smooth discharge. Since the conveying process is carried out in a closed pipeline, there is basically no dust pollution, and the conveyed materials will not leak. Improved working environment.

Tubular screw conveyor is driven by the motor to rotate the screw shaft. After the material enters the screw feeder, it moves forward with the displacement direction of the screw blade rotation. During this process, the gravity of the material itself and the distance between the screw feeder casing and the material Friction and other forces make the material continuously conveyed with the screw blade for a long time; generally, if the conveying distance is long, a suspension bearing will be added in the middle of the screw shaft to ensure that the equipment has enough power for material conveying.

Tubular screw conveyor offers various standard solutions for the handling of powdery or granular materials, different models of conveyors or feeders are available for grain (wheat bran, flour, corn, rice husk, wheat), chemical (fertilizer, plastic granules, washing powder), coal production (coal powder, dedusting ash), concrete production (fly ash, filler dust, silica fume), premixed building materials (dry plaster, sand, cement, additives), glass processing ( calcium carbonate, soda, sand) etc.), foundries (sand, bentonite) etc.

Long distance transportation

The diameter of the round pipe ranges from 100mm to 1250mm, and there are 12 specifications in total. It can transport 142 cubic meters per hour and the length can reach 70 meters.

Uniform conveying, not easy to block

The speed is fast (60-140 r/min), which ensures that the material is conveyed quickly and evenly, and the material is discharged smoothly without blocking the material.

Sealed structure, no dust

Sealed tube design, so when conveying powdery materials, it can avoid environmental pollution caused by dust overflow.

Flexible layout

It can be transported horizontally, inclined, and vertically (GX type inclination > 20°, LS type less than 15°), and can be connected with other equipment.

Flexibility

It can be fixed or mobile, and flexibly adapt to the needs of various production and transportation forms.

Customization

It is possible to select appropriate bearings, inlet and outlet forms, materials and other special machine accessories according to actual application needs.

Grain Tubular Screw Conveyor

Stainless Steel Tubular Screw Conveyor

| Model | Diameter (mm) |

Pitch (mm) |

Rotating speed (r/min) |

Capacity (m³/h) |

Rotating speed (r/min) |

Capacity (m³/h) |

Rotating speed (r/min) |

Capacity (m³/h) |

Rotating speed (r/min) |

Capacity (m³/h) |

|

| Small | 100 | 100 | 100 | 140 | 2.2 | 112 | 1.7 | 90 | 1.4 | 71 | 1.1 |

| 125 | 125 | 125 | 125 | 3.8 | 100 | 3 | 80 | 2.4 | 63 | 1.9 | |

| 160 | 160 | 160 | 112 | 7.1 | 90 | 5.7 | 71 | 4.5 | 56 | 3.6 | |

| 200 | 200 | 200 | 100 | 12.4 | 80 | 9.9 | 63 | 7.8 | 50 | 6.2 | |

| Small | 250 | 250 | 250 | 90 | 21.8 | 71 | 17.2 | 56 | 13.6 | 45 | 10.9 |

| 315 | 315 | 315 | 80 | 38.8 | 63 | 30.5 | 50 | 24.2 | 40 | 13.4 | |

| 400 | 400 | 355 | 71 | 62.5 | 56 | 49.3 | 45 | 38.6 | 36 | 31.7 | |

| Large | 500 | 500 | 400 | 63 | 97.7 | 50 | 77.6 | 40 | 62 | 32 | 49.6 |

| 630 | 630 | 450 | 50 | 138.5 | 40 | 110.8 | 32 | 88.6 | 25 | 69.3 | |

| 800 | 800 | 500 | 40 | 198.5 | 32 | 158.8 | 25 | 124.1 | 20 | 99.3 | |

Xinxiang Dahan tubular screw conveyor manufacturer specializes in screw conveyors. It has 15 years of production experience, complete models, low prices, and 1-year warranty. The material of the shell blades of this product is carbon steel and stainless steel. According to the particle size, conveying volume and conveying distance of conveying materials, reasonable selection and design can be made to ensure no material jamming, no arching, and smooth discharge. Free parameters and drawings are provided.

[Quality Assurance]: 30-day quality problem refund, 180-day quality problem replacement, 1-year warranty, lifetime maintenance.

[Service Guarantee]: 30 minutes to respond to demand, 24 hours on-site inspection, 72 hours free maintenance.

[Delivery Guarantee]: Regular models will be shipped within 24 hours, and customized models will be shipped within 7 days, which reduces the delivery cycle and saves user costs.

Address:China,Yanjin county forest park gate to the west 1000 meters north road.