Amaranth Seeds Screening Machine with its simultaneous grading and impurity removal capabilities, effectively removes impurities, broken seeds, discolored seeds, and immature seeds, retaining plump, healthy, high-quality seeds. It has become a key piece of equipment in seed breeding and processing. Our factory's amaranth seed screening machines cover various types, including test sieves, rotary vibrating sieves, and linear vibrating sieves, which can be customized to meet different needs, from small-batch laboratory testing and small-to-medium-batch processing to large-scale production lines.

The Amaranth Seeds Screening Machine offers non-standard customization capabilities, with up to 8 sieve layers for precise particle size differentiation. The machine height can be flexibly increased to easily connect with peripheral equipment such as feeding machines and packaging machines, creating an integrated production process. The discharge port supports 360° rotation adjustment and can change its shape and position according to collection needs, adapting to different workstation layouts. This highly customizable design allows the equipment to precisely meet the personalized needs of various amaranth seed processing methods, providing seed companies and planting bases with high-speed, flexible sorting solutions.

To cater to different customer screening scenarios and needs, our Amaranth Seeds Screening Machines are mainly divided into three categories: test sieves, vibrating sieves, and linear sieves. Each type has its own advantages, covering the entire spectrum of needs from laboratory testing to large-scale processing.

Test Sieves: These are specialized small devices for amaranth seed quality testing. They can hold 1-8 layers, with precisely controllable mesh size, accurately separating impurities and seeds of different sizes, providing data support for seed quality assessment and variety selection.

Vibrating Sieves: These are commonly used for amaranth seed screening due to their three-dimensional vibration trajectory. The equipment is equipped with a vertical vibrating motor, and the vibration frequency and amplitude are adjusted via an eccentric weight. Supporting 1-6 layers of mesh, they can simultaneously perform multiple tasks such as impurity removal, size grading, and saturation screening, achieving a screening accuracy of over 99%.

Linear Sieves: These use dual vibrating motors to generate a high-frequency linear vibration trajectory, driving the material forward uniformly. The adjustable tilt angle of the sieve surface, combined with multi-layered screens, enables continuous, high-volume impurity removal and grading, with a throughput far exceeding that of vibrating screens and test sieves.

The Amaranth Seeds Screening Machine can simultaneously remove impurities and grade seeds, with multiple types available to adapt to various scenarios; it supports non-standard customization such as 8-layer screens, and can be integrated with other equipment. It offers high screening accuracy and stable efficiency, reducing costs and improving efficiency in seed processing.

Improved seed quality: It removes empty, shriveled, and damaged seeds, retaining plump seeds and significantly improving germination rates.

Reduced pesticide use: Moldy and insect-infested seeds may carry pathogens or insect eggs; screening improves seed health, reducing the occurrence of pests and diseases later.

Saving labor costs: Traditional manual screening requires 10 people/day to process 1 ton of seeds, while the color sorter can process 500kg per hour, increasing efficiency by 200 times.

Promoting Variety Standardization: Seeds can be graded according to size and diameter, achieving variety standardization and increasing selling price by 10%-15%, thus enhancing growers' income.

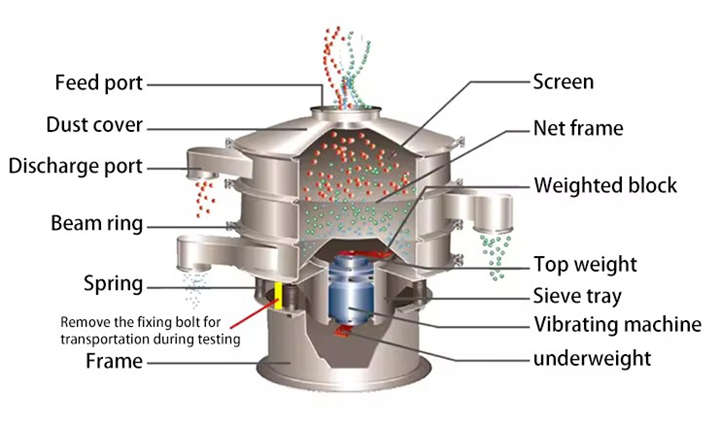

The core structure of the Amaranth Seeds Screening Machine is designed around stable support, accurate vibration, high-speed sorting, and convenient operation. All components work together to ensure screening accuracy and efficiency.

Screening Machine Base and Frame: The frame is mostly made of welded carbon steel or stainless steel, with a robust and shock-resistant structure that can offset the impact of vibration. The base is equipped with shock-absorbing springs to reduce noise and ground resonance during operation, while supporting the weight of the entire machine to ensure stability and prevent shifting during screening.

Vibration Drive System: The mainstream configuration is a vertical or horizontal vibrating motor, with some test sieves paired with a small vibrating screener. By adjusting the motor speed and the angle of the eccentric weight, the vibration frequency and amplitude can be flexibly controlled, providing a suitable trajectory for the seeds and driving them to flow evenly on the sieve surface, ensuring effective sorting.

Screening Box and Screen Assembly: The screening box has a closed or semi-closed structure to prevent seeds from flying and impurities from entering. The screens are primarily made of stainless steel woven mesh or perforated mesh, with apertures customized according to the amaranth seed size. Multiple layers (1-6 layers) are supported for graded screening. The screen frame features a quick-release design and is equipped with a screen cleaning device to prevent clogging and facilitate screen replacement and cleaning.

Feeding and Discharge Devices: The feed inlet is designed as an inclined or funnel shape to ensure even and continuous seed entry onto the screen surface, preventing localized accumulation that could affect screening. The discharge outlets are zoned according to screening grade, and their positions can be flexibly adjusted to adapt to different collection needs.

The Amaranth Seeds Screening Machine is based on the principle of vibration sorting and grading. A vibration drive system causes the screen surface to vibrate along a specific trajectory. During operation, amaranth seeds enter the screen surface evenly through the feed inlet and move regularly along the screen surface under the influence of vibration. Multi-layer precision screens are arranged in ascending order of aperture size. Fine impurities and shriveled seeds pass through the lower layers, while plump seeds are retained by different layers of screens according to their size, and finally separated and collected from their corresponding outlets.

Test Sieves Technical Specifications

| Mesh shape | Diameter | Effective screen surface diameter | H | |

| Min | Max | |||

| round | 75mm | 75mm | 65mm | 25mm |

| 200mm | 200mm | 185mm | 25mm, 50mm | |

| 300mm | 300mm | 275mm | 75mm | |

| square | 300mm | 300mm | 75mm | |

Vibrating Sieves Technical Specifications

| Model |

Diameter (mm) |

Feeding Size (mm) |

Frequency (RPM) |

Layers |

Power (kw) |

Capacity (kg/h) |

| DH-400 | 400 | <10 | <1500 | 1-5 | 0.18 | 100 |

| DH-600 | 600 | 0.25 | 200 | |||

| DH-800 | 800 | 0.55 | 500 | |||

| DH-1000 | 1000 | 0.75 | 800 | |||

| DH-1200 | 1200 | 1.1 | 1200 | |||

| DH-1500 | 1500 | 1.5 | 1800 | |||

| DH-1800 | 1800 | 2.2 | 2000 |

Linear Sieves Technical Specifications

| Model | Layer |

Screening Area (mm) |

Mesh Size (mesh) |

Particle Size (mm) |

Capacity (t/h) |

Power (kw) |

Vibration Direction Angle (°) |

Screen Inclination (°) |

Dual Amplitude |

| DZSF-520 | 1-6 layers | 500*2000 | 2-400 | 0.074-10 | ≤3 | 0.37×2 | 45-60 | 0-7 | 3-4.5 |

| DZSF-525 | 500*2500 | ≤5 | 0.37×2 | ||||||

| DZSF-612 | 600*1200 | ≤8 | 0.37×2 | ||||||

| DZSF-1020 | 1000*2000 | ≤12 | 0.75×2 | ||||||

| DZSF-1025 | 1000*2500 | ≤16 | 0.75×2 | ||||||

| DZSF-1030 | 1000*3000 | ≤20 | 1.1×2 | ||||||

| DZSF-1224 | 1200*2400 | ≤23 | 1.5×2 | ||||||

| DZSF-1525 | 1500*2500 | ≤28 | 1.5×2 | ||||||

| DZSF-1530 | 1500*3000 | ≤32 | 2.2×2 |

To ensure screening quality and accuracy, each of our screening machines can handle different particle sizes. The experimental sieve has the strongest grading capability, simultaneously separating into 8 particle size grades. Utilizing a multi-layer high-precision screen design with a finely graded aperture gradient, it is suitable for refined particle size analysis of small batches of seeds in the laboratory. The rotary vibrating screen combines 1-6 layers of adjustable screens with a three-dimensional vibration trajectory to achieve 7-level sorting while ensuring grading efficiency, suitable for small to medium batch processing. The linear vibrating screen focuses on large-scale operations, using multiple layers of linear screen surfaces to complete grading of 5 particle sizes, meeting the high-speed screening needs of large batches of seeds.

The mesh size of the Amaranth Seeds Screening Machine is flexibly matched to the screening stage and equipment type, with the mainstream range being 8-12 mesh. Finer mesh sizes are used for special fine screening scenarios.

Routine Impurity Removal: Amaranth seeds are approximately 1-2 mm in diameter. For initial removal of large impurities such as straw and leaves, an 8-mesh screen is commonly used. This mesh size corresponds to an aperture of approximately 2.36 mm, allowing all amaranth seeds to pass through smoothly while intercepting large particles of impurities.

Routine Fine Screening: To improve seed purity and remove some shriveled seeds and small impurities, a 10-mesh screen is a common choice. Its aperture is approximately 1.7 mm, retaining plump, qualified seeds while separating some smaller shriveled seeds and fine dust, meeting the purity requirements of most large-scale processing scenarios.

Special Fine Sorting: For fine requirements such as purification in seed industry laboratories or variety breeding, 12-mesh or even finer screens are used. A 12-mesh sieve with an aperture of approximately 1.4 mm can further screen out high-quality seeds with uniform particle size; for extremely high-precision sorting scenarios, even finer mesh sizes may be used.

When selecting an Amaranth Seeds Screening Machine, first consider the processing scale to determine the type of sieve—test sieve, vibrating sieve, or linear sieve; then select the number of sieve layers according to the required precision; and finally, consider the site and equipment integration requirements, utilizing non-standard customization services to select the appropriate screening equipment.

Equipment type should be selected based on processing scale: For small-batch testing scenarios such as laboratories and scientific breeding, test sieves are suitable. They have a small single-batch processing capacity but high grading accuracy, capable of subdividing into 8 particle size grades to meet seed quality analysis needs. For small-to-medium batch processing scenarios such as planting cooperatives and small seed companies, vibrating sieves are recommended, supporting 6-level grading, balancing efficiency and flexibility, and can simultaneously complete impurity removal and grading operations. For large-scale production scenarios such as large breeding bases and seed processing plants, linear vibrating sieves are required. They have a large processing capacity, can operate continuously, and their 5-level grading capability is fully suitable for mass production needs.

Grading capacity and sieve mesh should be selected based on accuracy requirements: Grading accuracy directly affects seed quality. For fine sorting scenarios, test sieves or vibrating sieves should be prioritized, paired with 10-12 mesh fine sieves, to accurately distinguish seeds of different particle sizes and plumpness, ensuring purity. For routine sorting scenarios, linear vibrating sieves or vibrating sieves with 8-10 mesh sieve combinations can be used, meeting basic purity requirements while also considering efficiency. By flexibly adjusting the sieve mesh size and grading levels, an optimal balance between cost and effectiveness can be achieved.

Choose based on scenario requirements: In actual use, additional requirements such as space, hygiene, and ease of operation must be comprehensively considered. If space is limited, compact test sieves or small vibrating sieves should be selected; for assembly line operations, linear vibrating sieves suitable for the production line are required. For high-end planting or food processing scenarios, equipment with stainless steel parts in contact with materials should be prioritized to ensure easy cleaning and no contamination.

DaHan Vibration Machinery Co., Ltd. has been deeply involved in the screening equipment field for 17 years and is a core manufacturer of Amaranth Seeds Screening Machines. We provide a full range of equipment including test sieves, vibrating sieves, and linear vibrating sieves, adapting to the needs of all scenarios from laboratory testing to large-scale production, with screening accuracy reaching over 99%. Personalized customization is supported; the sieve mesh size, number of equipment layers, and materials can be adjusted as needed to meet different grading and processing scale requirements. Constructed from high-quality steel and stainless steel, the equipment boasts a robust and easy-to-clean structure. Equipped with a stable vibration system and automatic screen cleaning device, it balances efficiency and durability. Furthermore, it can be customized for height, materials, and inlet/outlet configurations to integrate with your existing production equipment.

The Amaranth Seeds Screening Machine offers high efficiency in simultaneous impurity removal and grading, along with flexibility in providing multiple types and non-standard customization, making it suitable for various processing scenarios. Its precise sorting and convenient linkage ensure seed quality while improving production efficiency, making it an essential and practical piece of equipment for the amaranth seed industry, from breeding to mass production.

Address:China,Yanjin county forest park gate to the west 1000 meters north road.