The function of a Carbon Separator Vibration Siever is to screen and separate carbon materials. This equipment is configured according to different production needs. Common types include circular vibrating screens, ultrasonic vibrating screens, stainless steel vibrating screens, and carbon steel vibrating screens. In practice, their processing capacity ranges widely, from several kilograms to several tons per hour. Conventional screening mesh sizes typically range from 20 to 400 mesh, while ultrasonic vibrating screens can handle materials with mesh sizes of 200 to 600, or even higher, for separating ultrafine powders.

Carbon Separator Vibration Sievers are commonly used to screen and grade carbon powder or other powdered materials. Based on their operating principle and structural material, they can be categorized as circular vibrating screens, ultrasonic vibrating screens, stainless steel vibrating screens, and carbon steel vibrating screens. The following is a detailed introduction to these types: Circular Vibrating Screens

Circular vibrating screens, also known as rotary vibrating screens, are suitable for a variety of carbon materials, including activated carbon, graphite, carbon black, and carbon powder. Due to its high screening precision and efficiency, it is widely used in the screening of fine carbon powders. It can screen materials ranging from coarse particles to fine powders, with a common mesh range of 20 to 400 mesh, or even higher. Features: Multi-layer separation allows for the installation of multiple screens, simultaneously screening or filtering up to five different particle sizes for fine material grading. High screening efficiency is achieved, and the unique vertical vibration pattern creates a spiral motion across the screen surface, enabling rapid screening and increasing production output. Its compact structure and small footprint make it easy to move and install, making it ideal for production workshops with limited space. Screen changes are quick and easy to operate, allowing for quick replacement of different mesh sizes to meet varying production needs.

Ultrasonic Vibrating Screen

Ultrasonic vibrating screens are suitable for fine, lightweight, highly adhesive, or easily agglomerated carbon materials, such as nano-carbon powder, fine graphite powder, and carbon black. When the particle size is very small (less than 200 mesh), conventional vibrating screens are prone to mesh clogging. Ultrasonic vibrating screens, on the other hand, are primarily used for screening fine powders, with mesh sizes typically ranging from 200 to 600, and even exceeding 800 mesh.

Features: This system addresses mesh clogging by superimposing high-frequency, low-amplitude ultrasonic vibrations on the mesh of a conventional vibrating screen. This ultrasonic wave effectively breaks down the adhesion of the material surface, preventing it from clogging the screen mesh, significantly improving screening efficiency and accuracy. The high screening accuracy allows for the effective screening of fine powders that conventional equipment cannot handle, ensuring high screening quality. This reduces screening times and avoids the hassle of repeated machine downtime and cleaning due to mesh clogging, reducing labor intensity and improving production efficiency.

Stainless Steel Vibrating Screens

Stainless steel vibrating screens are suitable for processing carbon materials with stringent material requirements, particularly those used in food or high-purity chemicals, such as certain high-purity activated carbons. The stainless steel construction prevents material contamination. Features: Corrosion resistance. Stainless steel (such as 304 and 316L) offers excellent corrosion resistance and is resistant to rust, making it suitable for handling some mildly corrosive carbon materials. Its smooth surface makes it easy to clean, meeting hygiene standards for industries like food and preventing cross-contamination. The material is durable and resistant to oxidation, extending the life of the equipment.

Carbon Steel Vibrating Screen

Carbon steel vibrating screens are suitable for screening carbon materials such as common industrial-grade carbon powder and coarse graphite powder, where equipment material requirements are low, non-corrosive, and budgets are limited. Features: Compared to stainless steel equipment, carbon steel equipment has lower manufacturing costs and offers a competitive price. Carbon steel is strong and can withstand heavy material loads. It is often painted or treated with an anti-corrosion agent to extend its life, but its corrosion resistance is not as good as stainless steel.

The core advantage of the Carbon Separator Vibration Siever lies in its ability to precisely classify and remove impurities from the material, significantly improving production efficiency and automation. It also provides solutions to the screening challenges of specialized materials. Its high adaptability and wide range of applications make it an indispensable production tool.

Precise Classification and Impurity Removal: By precisely controlling the mesh size, it can classify carbon materials of varying particle sizes, ensuring a uniform, standard-compliant product. Furthermore, the screening process effectively removes coarse particles, agglomerates, and impurities from the material, improving product purity. This precise classification capability is particularly critical for high-value-added carbon materials, such as lithium battery anode materials and high-end activated carbon. Improving Production Efficiency and Automation: The vibrating screener enables continuous, automated operation. Its adjustable vibration frequency and amplitude adapt to the screening needs of different materials, allowing it to process large volumes of material in a short period of time, significantly improving overall production line efficiency and output. Solve the screening challenges of special materials: Certain carbon materials, such as fine carbon powder or nano-carbon black, have very strong adsorption properties, are prone to agglomeration, or carry static electricity. Conventional screening methods can easily cause screen clogging, resulting in low screening efficiency or even inability to perform screening. Ultrasonic vibrating screens superimpose high-frequency ultrasonic waves on the screen, effectively breaking down static electricity and agglomeration on the powder surface, preventing material from adhering to the screen mesh, thereby enabling the screening of fine powders without clogging.

Adaptable and Widely Applicable: The structure and material of the vibrating screen can be customized to meet different needs. Circular vibrating screens are compact and require little space, making them suitable for multi-layer grading. Stainless steel equipment is suitable for carbon materials with strict hygiene and cleanliness requirements, such as food-grade activated carbon, effectively preventing material contamination. Carbon steel equipment, on the other hand, is less expensive and suitable for industrial carbon powders with less demanding material requirements.

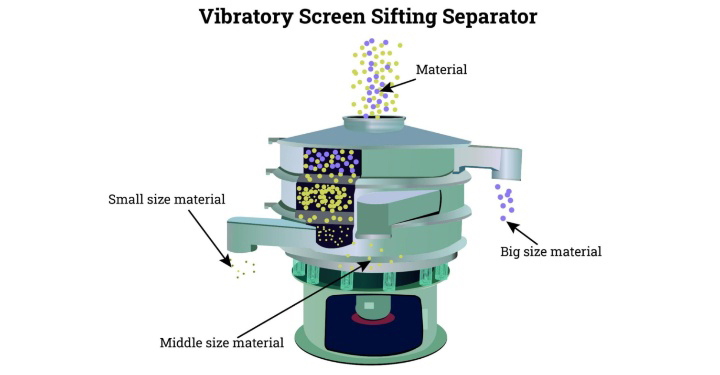

The core operating principle of the Carbon Separator Vibration Siever is to utilize the excitation force generated by a vibrating motor to cause the screen to move in three dimensions, thereby driving the material on the screen surface for grading and separation. The vibrating motor, located at the bottom or side of the device, is equipped with an eccentric weight. When the motor is activated, the eccentric weight generates a complex vibration pattern in vertical, horizontal, and diagonal directions. This unique three-dimensional motion pattern is the key to its screening performance. Unlike traditional linear vibrating screens that only move in a single direction, the three-dimensional vibration causes the material to form a spiraling, bouncing path across the screen. Driven by the three-dimensional vibration force, the carbon material particles move forward in a spiral, parabolic pattern along the screen surface. During this process, particles smaller than the screen openings pass through the screen and fall to the next layer, while particles larger than the openings continue forward and are eventually discharged through the discharge port. Vertical vibration forces the material to repeatedly leave and contact the screen surface, preventing blockage and helping small particles to sink quickly. Horizontal and diagonal vibrations drive the material in a spiraling motion across the screen surface, ensuring that the material fully and evenly covers the entire screen, maximizing screening area and efficiency. Vibrating screens are typically designed with multiple layers, each equipped with screens of varying mesh sizes. When material enters the feed port, the coarsest particles are first separated by the upper screen, followed by the remaining material passing through successively finer screens, ultimately achieving multi-level sorting and grading of carbon materials. Furthermore, the vibrations generated during movement effectively break up aggregates in the material and separate impurities and coarse particles from qualified products, significantly improving product purity and quality. Conventional vibrations can easily cause clogging of fine, easily adherent carbon materials (such as nano-sized carbon powder). Ultrasonic vibrating screens, however, superimpose high-frequency, low-amplitude ultrasonic vibrations on the screen surface. This additional vibration effectively breaks down static electricity and adhesion on the material surface, eliminating clogging issues and ensuring smooth screening of fine powders. In summary, the Carbon Separator Vibration Siever, through its unique three-dimensional vibration pattern, combined with a multi-layered screen structure and optional ultrasonic technology, enables precise grading and separation of carbon materials, making it an indispensable core device in carbon industry production lines.

The Carbon Separator Vibration Siever boasts a compact and ingenious design. It primarily consists of a vibrating motor, a screen frame, multiple layers of screen mesh, and shock-absorbing springs. These components work together to precisely grade and separate carbon materials through three-dimensional vibration. The following are its core components:

Main body (screen frame): This is the framework of the vibrating screen, typically constructed of carbon steel or stainless steel. The interior of the body is hollow, housing the material and supporting the screen mesh. The body features inlet, outlet (usually multiple layers, corresponding to different particle sizes), and debris removal ports.

Vibrating motor: This is the power source for the entire device. A vibration motor is a special type of motor with adjustable eccentric weights mounted at each end. When the motor rotates at high speed, the eccentric weights generate powerful excitation force, causing the entire screen to produce complex motion in three dimensions: vertical, horizontal, and tilt.

Shock-absorbing springs: Located between the screen base and the ground, they serve as a critical buffering component for the vibrating screen. The primary function of the shock-absorbing spring is to isolate vibrations, effectively isolating the vibrations generated by the vibrating screen from the ground, preventing them from being transmitted to the factory floor or surrounding equipment, and thus protecting the equipment and building structure. The support spring provides a stable support for the entire screen and helps control the screen's motion trajectory, ensuring that it vibrates according to the preset motion pattern.

Screen and Frame: The screen is made of woven stainless steel. Its mesh size (aperture) is the key parameter determining screening accuracy. Screens of varying mesh sizes can be installed depending on the particle size to be classified. The frame, to which the screen is fastened, is typically constructed of a wooden or metal frame. Bouncing balls (or cleaning rings) are typically installed beneath the frame to continuously strike the bottom of the screen during vibration, preventing material from clogging the mesh and improving screening efficiency.

Dust Cover and Sealing Ring: The dust cover, located on the top layer of the screen, prevents dust generated during screening and maintains a clean operating environment. The sealing ring, installed between each layer of the screen frame, provides a good seal, preventing material leakage during screening and ensuring classification accuracy.

As a screening device, the Carbon Separator Vibration Siever is widely used in many industries requiring precise classification and impurity removal of carbon materials. In the carbon black industry, carbon black products are graded according to different particle sizes to meet the particle size distribution requirements of various applications (such as tires, inks, and plastics). They also screen out coarse particles, coke, and impurities during the production process to ensure product purity and improve product quality. In the activated carbon industry, activated carbon products of varying particle sizes are produced to suit various applications, such as water treatment, air purification, and solvent recovery. Fine powdered activated carbon can be screened for use in applications such as food, where fineness is a high requirement. In lithium battery material processing, strict particle size control is required during the production of negative electrode materials (such as artificial graphite, natural graphite, and hard carbon). Vibrating screens are used to precisely grade these materials to ensure battery consistency and performance. They remove coarse particles and impurities from the negative electrode material, preventing damage to the battery's internal structure and improving its cycle life and safety. In the graphite industry, graphite powder of varying particle sizes is graded for use in various applications, such as lubricants, conductive materials, and refractory materials. During the purification and processing of high-purity graphite, vibrating screens are used to remove impurities and improve product purity. They are also used in other fields, such as the abrasives industry (for grading carbon-based abrasives such as silicon carbide), the metallurgical industry (for grading and removing impurities in graphite electrodes and carbon products), the chemical industry, and building materials. Carbon Separator Vibration Sievers can be applied wherever the screening and grading of materials such as carbon powder and carbon granules is involved. In short, Carbon Separator Vibration Sievers play an indispensable role in the production, processing, and application of carbon materials. Their precise screening capabilities are key to ensuring product quality and improving production efficiency.

In the production and processing of carbon materials, Carbon Separator Vibration Sievers are one of the key steps in ensuring that materials meet process requirements. In actual applications, the selection of equipment is based on the specific material's particle size distribution, production scale, and required output purity. Different vibrating screen models have their own specific applications. For example, screening some carbon materials may require more frequent screen changes, while others may require specific vibration frequencies. The actual performance of the equipment is affected by multiple factors, including but not limited to the material's moisture content, static charge, and particle shape. Therefore, matching the equipment configuration with the material's characteristics is crucial to ensuring a successful screening process.

Address:China,Yanjin county forest park gate to the west 1000 meters north road.