Carob Seed Sieving Linear Vibrating Sieve Machine is used for sieving and grading carob seeds. To remove unwanted impurities or substandard carob seeds, a linear vibrating sieve can be used. Sieving carob seeds can be made of stainless steel, carbon steel, or plastic. Common sieving tasks include removing larger impurities (such as leaves and stones) and separating fine powders. The sieve has a mesh size of 10-70 mesh.

The Carob Seeds Sieving Linear Vibrating Sieve Machine uses dual motors for efficient screening. Available in 304 stainless steel (food grade), carbon steel (economical and durable), or PP plastic (anti-static) to meet diverse production needs. The machine is equipped with interchangeable sieves ranging from 10-70 mesh. The coarse screen (10-12 mesh) removes large impurities such as leaves and stones, the medium screen (20-40 mesh) separates whole seeds from broken grains, and the fine screen (60-70 mesh) separates fine powder for use in high-value-added products. A specially designed anti-blocking screen, combined with a bouncing ball cleaning device, effectively eliminates sticking issues caused by the oil content (7%) of carob seeds. Standard features include variable frequency speed control (15-25Hz) and an adjustable amplitude of 4-6mm. With a processing capacity of 1-5 tons/hour, it accommodates feedstock with a moisture content of less than 8%. Integrated dust removal and metal detection are also available to ensure screening accuracy and product quality.

Based on the material, Carob Seeds Sieving Linear Vibrating Sieve Machines can be divided into three categories: stainless steel, carbon steel, and plastic. Each type of sieve machine has its own unique structural and technical parameters. Stainless steel linear vibrating sieves are the preferred choice in the food processing industry due to their excellent hygiene and durability. Carbon steel sieves and plastic sieves are suitable for cost-sensitive non-food applications and specific applications with specific requirements for metal contamination, respectively. Stainless Steel Linear Vibrating Screens

Stainless steel linear vibrating screens are typically made of 304 or 316L stainless steel, offering excellent corrosion resistance. They effectively resist the oil and moisture in carob seeds and prevent rust. Their smooth surface and design eliminate dead corners, making them easy to clean and disinfect, meeting food hygiene standards. These screens feature a sturdy structure and high mechanical strength, enabling stable, long-term, continuous operation.

Carbon Steel Linear Vibrating Screens

Carbon steel linear vibrating screens are often used in non-food-grade screening applications where material requirements are less stringent, or as a lower-cost alternative. Due to the low price of carbon steel raw materials, the overall cost of these screens is relatively low. They offer excellent mechanical strength and rigidity, allowing them to withstand high excitation forces. However, carbon steel has poor rust resistance and requires painting or anti-corrosion treatment. Despite this, rust may develop over time, making them unsuitable for food hygiene.

Plastic Linear Vibrating Screens

Plastic linear vibrating screens are relatively uncommon in carob seed screening and are typically used only for small-batch screening in laboratories or specialized processes with strict metal contamination control requirements. This sieving machine is primarily made of polymer materials, making it lightweight and easy to move and install. It offers excellent corrosion resistance, effectively resisting corrosion from a variety of chemicals, and eliminates the risk of metal ion precipitation. However, the mechanical strength and rigidity of plastic are far lower than those of stainless steel and carbon steel, making it unsuitable for large-scale, high-intensity screening.

The Carob Seeds Sieving Linear Vibrating Sieve Machine not only significantly improves production efficiency but also ensures product quality. Its advantages primarily lie in its screening capabilities, large throughput, ease of maintenance, excellent sealing performance, strong adaptability, and wide application range.

Sieving and Grading: The linear vibrating screen ensures that material passes through the screen quickly and evenly. It can be configured with multiple layers of screens to meet specific needs, completing multi-stage sorting and grading of carob seeds simultaneously, effectively separating large particles, qualified products, and fine powder, significantly improving production efficiency and product quality. Large Processing Capacity and Continuous Operation: Due to its operating principle and structural design, linear vibrating screens can handle large batches of material, enabling continuous screening. This makes them ideal for large-scale, continuous carob seed processing lines, meeting the high-volume needs of enterprises. Simple Structure and Easy Maintenance: The linear vibrating screen has a relatively simple structure, primarily consisting of a screen box, a vibrating motor, a vibration damping device, and a screen mesh. This design makes daily maintenance and upkeep of the equipment very convenient.

Good Sealing Performance: Linear vibrating screens typically utilize a fully enclosed structure, effectively preventing dust and material from flying around. This prevents contamination of carob seeds by external impurities, which is particularly important in the food processing industry.

Adaptable and Widely Used: In addition to carob seeds, linear vibrating screens are widely used in a variety of industries, including food, chemicals, and building materials, for screening, impurity removal, and grading of various granular and powdered materials. For carob seeds, linear vibrating screens can flexibly adjust parameters and configurations to suit different processing purposes, such as whole seed screening and crushed powder grading, demonstrating strong process adaptability.

The Carob Seeds Sieving Linear Vibrating Sieve Machine plays a multifunctional role in the processing process, with applications far beyond simple sieving. It operates throughout multiple key steps from raw materials to finished product, primarily for initial impurity removal, precise grading, powder screening, and product safety assurance, providing a solid foundation for high-quality carob seed processing.

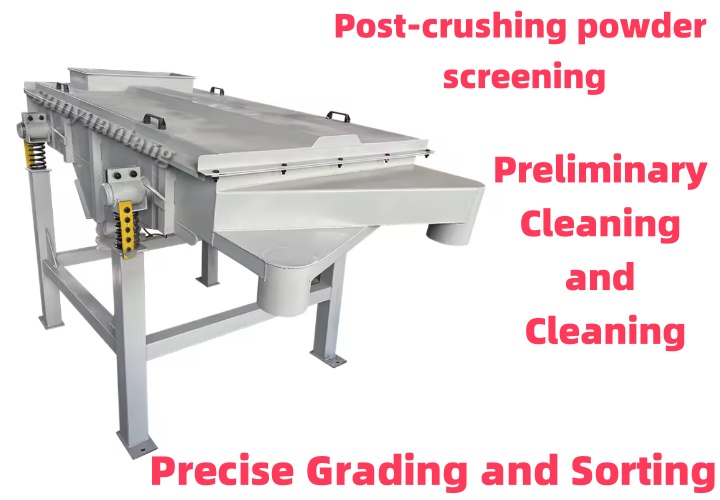

Preliminary Cleaning and Cleaning: Before carob seeds enter further processing, linear vibrating screens are used to remove impurities. This includes dust, sand, straw, leaves, and other impurities that may have entered during harvesting, transportation, and storage. By configuring screens with varying apertures, these impurities can be effectively separated, ensuring the purity of the material for subsequent processing and improving the quality and safety of the final product.

Precise Grading and Sorting: Carob seeds vary in size and shape. Linear vibrating screens can accurately grade carob seeds according to varying particle size requirements. For example, large, plump seeds can be separated for specific uses, while smaller or irregular seeds may be used in other products. This grading process standardizes product specifications and improves market competitiveness.

Post-crushing powder screening: After carob seeds are crushed or ground, a linear vibrating screen is used to sieve the powder. It separates fine powder from coarse particles, ensuring a uniform powder size. This is crucial for the production of carob gum, flour, or other powdered products, as a uniform particle size ensures stable product properties such as solubility and viscosity.

The Carob Seeds Sieving Linear Vibrating Sieve Machine's precise screening and large processing capacity ensure stable production line operation. Its easy-to-maintain design reduces equipment downtime and ensures continuous production. When selecting a specific machine, first, determine whether to use stainless steel, carbon steel, or other materials based on material properties and hygiene requirements. Second, select the appropriate sieve size and number of screen layers based on the required processing capacity and grading accuracy. Finally, consider factors such as equipment sealing, vibrating motor power, and noise control, taking into account the production environment.

Address:China,Yanjin county forest park gate to the west 1000 meters north road.