Flow-Through Ultrasonic Sieving is a continuous screening technology upgraded from traditional ultrasonic vibrating screens. Its core consists of an ultrasonic vibrating screen and a dust collector, seamlessly connected via a sealed pipeline. Unlike intermittent screening equipment, it employs a continuous closed-loop design of feeding-screening-discharging, rapidly completing fine powder classification. The screen body material can be selected from carbon steel, 304/316L stainless steel, or PP, depending on requirements. The maximum screen diameter is 2 meters, and the screening mesh covers 40-600 meshes. It supports multi-layer screen configurations for multi-level classification. The dust collector typically uses a pulse bag filter or a cyclone dust collector; the former is suitable for fine dust collection, while the latter is suitable for medium and coarse dust. The two can be flexibly combined according to the material's dust characteristics to ensure a dust collection rate of over 99%.

Flow-Through Ultrasonic Sieving combines the advantages of ultrasonic screening and dust removal. High-frequency ultrasonic waves break up material agglomerates and prevent screen clogging, while the accompanying dust collector achieves a dust collection rate of over 99%, eliminating dust pollution.

Fully Enclosed Negative Pressure Conveying: The equipment adopts a fully enclosed structure, coupled with a negative pressure dust collection system, to prevent dust spillage.

Energy Saving: Collected dust can be recycled, reducing material loss and lowering production costs. The material loss rate can be controlled to within 0.5%.

Stable Screening: Ultrasonic screen cleaning ensures long-term stable screening accuracy within ±1%, increasing throughput by 30%-80% compared to traditional screening equipment. The negative pressure environment of the dust collector further assists material flow, improving screening efficiency.

Multi-Mode Operation Support: Supports 24-hour continuous or pulse operation modes, and can switch between single-layer/multi-layer screening according to production needs.

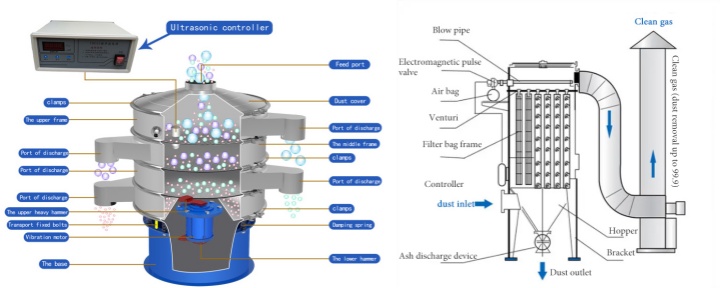

Flow-Through Ultrasonic Sieving integrates the screening function of an ultrasonic vibrating screen with the purification function of a dust collector, forming a complete material handling system. Its core structure can be divided into two main parts the main structure of the ultrasonic vibrating screen and the main structure of the dust collector.

Screen: Made of high-carbon steel, stainless steel, PP, etc., it is kept flat by tension to ensure material movement along the vibration direction. The screen mesh size can be customized according to screening requirements.

Vibration Motor: Generates high-frequency mechanical vibration, driving the screen box to vibrate in multiple planes, increasing the speed at which material passes through the screen.

Ultrasonic Generator and Transducer: The ultrasonic generator produces high-frequency electrical signals, which the transducer converts into mechanical vibration and transmits to the screen. Through 20-40kHz high-frequency vibration, cavitation and suspension effects are generated, decomposing adhering substances and preventing mesh clogging.

Dust Collector Housing: Serves as the top-enclosed structure of the dust collector, housing the filter bag assembly and pulse-jet cleaning device. The upper housing provides space for the clean air chamber, ensuring that filtered clean gas is collected and discharged.

Dust hopper: Located at the bottom of the dust collector, it collects dust that falls from the surface of the filter bags. The dust hopper is designed with dust flow in mind, typically featuring an inclined angle and a dust discharge device to ensure smooth dust removal.

Filter bags: Made of high-performance filter materials such as polyester fiber and polyphenylene sulfide fiber, offering excellent filtration accuracy and corrosion resistance.

When material enters the ultrasonic vibrating screen through the inlet, the vibrating motor generates three-dimensional vibration, causing the material to be evenly dispersed and layered on the screen surface. Simultaneously, the ultrasonic system transmits high-frequency vibrations to the screen mesh, breaking up agglomerates formed by electrostatics and molecular attraction, and promptly clearing blockage particles from the screen openings, ensuring screen permeability and achieving precise and rapid grading. During this process, the dust collector starts simultaneously, creating a negative pressure environment in the screening chamber through pipes, rapidly drawing in the dust generated during screening. After filtration by the filter bags or cyclone separation, the dust is collected in the ash hopper, while clean air is discharged in compliance with standards.

| Model | Effective screening diameter | Screen mesh size range | No of layers | Power | Online quotation |

| DHC-400 | 340 | 80-600MESH | 1-3 LAYERS | 0.18KW |

|

| DHC-600 | 540 | 80-600MESH | 1-3 LAYERS | 0.25KW |

|

| DHC-800 | 730 | 80-600MESH | 1-3 LAYERS | 0.55KW |

|

| DHC-1000 | 900 | 80-600MESH | 1-3 LAYERS | 0.75KW |

|

| DHC-1200 | 1100 | 80-600MESH | 1-3 LAYERS | 1.1KW |

|

| DHC-1500 | 1400 | 80-600MESH | 1-3 LAYERS | 1.5KW |

|

| DHC-1800 | 1700 | 80-600MESH | 1-3 LAYERS | 2.2KW |

|

Flow-Through Ultrasonic Sieving, with its integrated advantages of high-speed sieving and dust purification, is precisely suited for industries such as food, pharmaceuticals, chemicals, and new energy that demand both high cleanliness and sieving precision.

Food Industry: In the processing of fine powders such as flour, starch, baking soda, protein powder, and cocoa powder, the equipment can achieve continuous grading and impurity removal. The ultrasonic system breaks up material agglomerates, ensuring uniform sieving, while the dust collector simultaneously collects airborne dust, preventing food contamination and workshop dust.

Pharmaceutical Industry: Suitable for sieving ultrafine powders of traditional Chinese medicine, raw material powders of Western medicine, and health product powders. The parts of the equipment that come into contact with materials are made of 316L stainless steel, eliminating dead corners and meeting the particle size control requirements of pharmaceuticals; the dust collector efficiently collects dust, preventing cross-contamination and meeting pharmaceutical industry certifications and requirements.

Chemical Industry: Used for sieving easily dusty and agglomerated materials such as paint powder, dye powder, plastic powder, and rubber powder. The ultrasonic system solves the problem of fine powder clogging, improving screening efficiency by 30%-80%; the dust collector controls dust collection rate above 99%, avoiding dust explosion risks and environmental pollution, and ensuring safe operation in the workshop.

New Energy Industry: Suitable for high-precision screening of lithium battery cathode material powder, anode material powder, ceramic powder, etc. The equipment supports 600-mesh fine powder screening, ensuring uniform particle size distribution and improving battery performance; the dust collector simultaneously treats ultrafine dust generated during screening, preventing dust from entering the equipment circuitry or affecting operator health, meeting the clean production standards of the new energy industry.

Flow-Through Ultrasonic Sieving can be integrated with cleanroom feeding stations, mixers, feeders, packaging machines, etc., to form a complete automated production line, achieving high-speed, clean, and continuous material handling through the synergistic effect of the equipment.

Flow-Through Ultrasonic Sieving+ Cleanroom Feeding Station: The cleanroom feeding station uses a negative pressure suction system to draw materials into the feeding hopper, and a dust collector filters out dust. The processed material then enters the ultrasonic vibrating screen's feed inlet directly through a sealed channel. Its airtight design reduces dust emissions during material dumping, meeting cleanroom requirements. Automated feeding eliminates the need for manual bag opening and emptying, reducing labor intensity and preventing material from coming into contact with external contaminants. The system is compatible with various packaging formats, including ton bags and small bags, and supports material handling from 25kg/bag to 1 ton/bag.

Flow-Through Ultrasonic Sieving+ Mixer: The qualified product outlet of the ultrasonic vibrating screen is directly connected to the mixer's feed inlet via a screw conveyor or pneumatic conveying device, forming a continuous process from screening to mixing. A dust collector simultaneously handles dust during screening and mixing, ensuring a clean workshop environment. The screened material directly enters the mixer, avoiding secondary contamination or material loss during intermediate transfer. The ultrasonic vibrating screen pre-removes large particles and impurities, improving mixing uniformity and product consistency. Reducing material handling frequency lowers equipment energy consumption and maintenance costs.

Flow-Through Ultrasonic Sieving + Feeder: The feeder is installed above the ultrasonic vibrating screen inlet, controlling material flow through frequency conversion. A dust collector simultaneously handles feeding dust. Uniform feeding prevents material accumulation or interruption during screening, improving screening efficiency and accuracy. Uniform feeding also reduces the impact of material on the screen, extending screen life.

Flow-Through Ultrasonic Sieving + Packaging Machine: The qualified product outlet of the ultrasonic vibrating screen is connected to the packaging machine inlet via a conveyor. A dust collector simultaneously handles packaging dust. Some systems integrate an automatic weighing module, achieving full automation of the screening → metering → packaging process. Direct packaging of screened materials reduces transfer time, achieving a packaging speed of 200-500 bags/hour. Ultrasonic vibrating screens ensure uniform particle size, and high-precision weighing modules improve product qualification rates. Dust collectors handle dust and recover valuable materials, reducing production costs.

Dahan Vibration Machinery is a source manufacturer of integrated screening and dust removal equipment, specializing in the R&D and manufacturing of Flow-Through Ultrasonic Sieving for over 20 years. We independently master all core technologies of ultrasonic systems. Our equipment is compatible with carbon steel, stainless steel, and PP materials, with a maximum screening mesh of 600 mesh and a dust collection rate of over 99%. We support non-standard customization, allowing flexible adjustments to screen size, feed/discharge structure, and dust removal solutions to meet the needs of various industries such as food, pharmaceuticals, and new energy. ISO quality system certified, we can customize suitable screening solutions based on your production site requirements.

Flow-Through Ultrasonic Sieving integrates functions, retaining the high speed and precision of ultrasonic sieving while solving the problem of dust pollution. It provides an ideal solution for enterprises to achieve high-speed and clean fine powder sieving, and is an important direction for upgrading sieving equipment in modern industrial production.

Address:China,Yanjin county forest park gate to the west 1000 meters north road.