The Industrial Ultrasonic Sieving System offers high precision, anti-clogging mesh, self-cleaning, and continuous operation. The system supports stacking 1–5 layers of screens for multi-stage screening. Screen sizes range from 20 to 635 mesh, approximately 850 microns to 20 microns, with some options reaching micron levels. Output generally ranges from 1 to 10 tons per hour, depending on the material properties and screen mesh size. Ultrasonic devices are available in door-type configurations for easy maintenance and inspection, as well as air-protected configurations to prevent oxidation and moisture. The Industrial Ultrasonic Sieving System is particularly suitable for screening fine, easily agglomerated, or statically charged materials such as titanium dioxide, carbon powder, metal powder, graphite, and silica powder. These materials have small particle sizes and are prone to adsorption, agglomeration, or statically charged adhesion to the screen. Conventional screening methods are prone to clogging and inefficiency, while ultrasonic screening technology improves screening efficiency and accuracy.

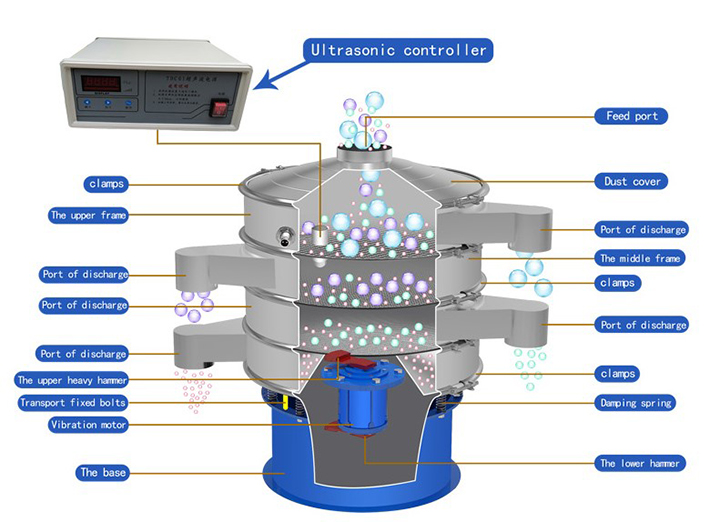

The components of the Industrial Ultrasonic Sieving System include an ultrasonic controller, which controls the vibration frequency; a feed inlet, which allows material to enter the equipment; a dust cover, which prevents dust from rising; a discharge outlet, which discharges the screened material; an upper and middle frame, which supports the screen and forms the screening structure; clamps, which secure the structure; upper and lower weights, which adjust the vibration direction and amplitude; a vibration motor, which provides the vibration force; a shock-absorbing spring, which cushions vibration; transport bolts, which secure the equipment during transport; and a base, which provides support for the entire system. After entering the equipment through the feed inlet, the material is screened through multiple layers of screens, and finally discharged through different discharge outlets.

The Industrial Ultrasonic Sieving System prevents fine particles from clogging the mesh, increasing screening efficiency by over 50%. The self-cleaning properties of ultrasonic waves increase screen utilization by 80%, while also reducing mechanical wear and extending screen life. This system is particularly suitable for grading highly viscous and easily agglomerated materials, significantly improving screening accuracy compared to traditional methods. It can meet the stringent ultrafine powder requirements of industries such as pharmaceuticals, chemicals, and battery materials. Furthermore, its non-mechanical vibration characteristics enable it to safely handle oxidizable and explosive materials, such as metal powders and pharmaceutical raw materials, making it widely applicable.

| Model | Effective screening diameter | Screen mesh size range | No of layers | Power | Online quotation |

| DHC-400 | 340 | 80-600MESH | 1-3 LAYERS | 0.18KW | |

| DHC-600 | 540 | 80-600MESH | 1-3 LAYERS | 0.25KW | |

| DHC-800 | 730 | 80-600MESH | 1-3 LAYERS | 0.55KW | |

| DHC-1000 | 900 | 80-600MESH | 1-3 LAYERS | 0.75KW | |

| DHC-1200 | 1100 | 80-600MESH | 1-3 LAYERS | 1.1KW | |

| DHC-1500 | 1400 | 80-600MESH | 1-3 LAYERS | 1.5KW | |

| DHC-1800 | 1700 | 80-600MESH | 1-3 LAYERS | 2.2KW |

Based on different application scenarios and design features, industrial ultrasonic sieving systems are categorized as external or internal types based on transducer installation method, and as rotary vibrating screens, linear screens, and airflow screens based on screen type.

In external ultrasonic sieving systems, the transducer is mounted on the outside of the screen frame, transmitting vibrations to the screen mesh via a conductive rod. This offers the advantage of ease of maintenance and suitability for large-scale screen modification, but energy transmission may result in loss.

In internal (integrated) ultrasonic sieving systems, in which the transducer is embedded directly within the screen frame, offer more efficient vibration transmission and high energy utilization, making them suitable for high-precision screening. However, their structure is more complex, requiring disassembly of the equipment for maintenance.

Rotary Vibrating Screen Ultrasonic System: Suitable for circular rotary vibrating screens, it effectively eliminates static adsorption of fine powders and solves screen clogging issues for materials larger than 400 mesh. It increases screen life by more than three times. It is suitable for fine powder screening and high-precision screening applications.

Linear Screen Ultrasonic System: Used with linear vibrating screens, ultrasonic vibrations assist the screen mesh, enhancing material flowability. It is suitable for screening granular or fluid materials. Its throughput reaches up to 5 tons/hour (depending on the material).

Airflow Screen Ultrasonic System: Incorporating airflow screening technology, it is used for ultrafine powders such as graphite and pharmaceutical powders. It effectively prevents fine powder from adhering to the screen mesh, achieving a screening accuracy of ±2μm, ensuring material purity and uniform grading.

Compared to traditional screening equipment, the Industrial Ultrasonic Sieving System offers advantages such as stable amplitude, low noise, and reduced energy consumption, significantly reducing maintenance costs and downtime. When selecting a system, the appropriate ultrasonic frequency and power should be determined based on material properties (such as particle size, moisture content, and viscosity), required output, and screening accuracy, while also considering the equipment's durability and ease of maintenance. External systems are suitable for small to medium production volumes and low-viscosity materials. Built-in ultrasonic systems are suitable for high-precision and highly viscous materials. Vibrating screen systems are suitable for materials with large particles and low moisture content and are commonly used in the mining and chemical industries. Linear screens are suitable for fine powders and viscous materials and are widely used in the pharmaceutical and food industries. Airflow screens are suitable for ultrafine powders and lightweight particles and are often used for high-purity materials.

Address:China,Yanjin county forest park gate to the west 1000 meters north road.