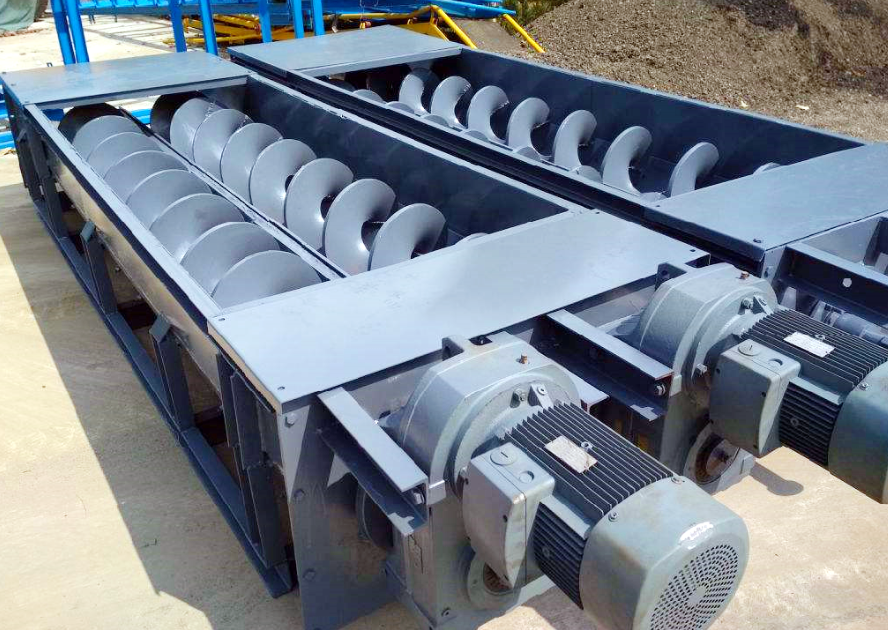

Kitchen waste double shaft screw conveyor is a mechanical equipment specially used for conveying high water content and high viscosity materials such as restaurant kitchen waste and organic wet garbage. In view of the characteristics of kitchen waste that are easy to rot, easy to entangle, high water content and many impurities, the equipment adopts a double screw shaft structure to realize the synchronous transportation, mixing and crushing of materials.

The closed design effectively controls the diffusion of odor and the overflow of leachate, ensuring environmental hygiene. In addition, some designs can also perform preliminary squeezing and dehydration of kitchen waste during the transportation process, laying the foundation for subsequent resource processing (such as anaerobic fermentation and composting), which is an indispensable key equipment in the pretreatment of kitchen waste.

The kitchen waste double-axis screw conveyors are mainly divided into two categories according to the structural form of the screw shaft: double-axis screw conveyors with shafts and double-axis screw conveyors without shafts. They have significant differences in structure, applicable materials, and transportation performance.

|

Comparison items |

Double-axis screw conveyor with shaft |

Double-axis shaftless screw conveyor |

|

Spiral structure |

Blades are welded on each screw shaft, with a central shaft support in the middle |

No central shaft, thick spiral belt structure |

|

Material adaptability |

Suitable for organic waste with moderate moisture content and no strong entanglement |

Suitable for materials with high moisture content, high viscosity and easy entanglement |

|

Anti-entanglement ability |

Generally, it is easy to block when encountering fibrous materials |

Strong, suitable for conveying mixtures of sundries such as peels, vegetable roots, and plastic bags |

|

Conveying efficiency |

High conveying efficiency and low energy consumption |

Slightly lower conveying efficiency, but strong processing capacity |

|

Common uses |

Conveying of more regular wet garbage, or connecting and transmitting process sections |

More widely used in the treatment system of food waste containing fiber, grease, and soup |

Two seamless steel pipes are installed in the U-shaped trough structure, and a solid screw is installed in each pipe, one of which is left-handed and the other is right-handed. When working, the two screws rotate through a pair of gears at the shaft extension position. Due to the rotation of the screw body, the material moves axially, thereby achieving the purpose of conveying kitchen waste. The spiral blades during the rotation process squeeze, stir and push the material, which has a certain homogenization and pretreatment effect. Some models can also be linked with the crushing device to achieve crushing while conveying.

Blade design: The blade shape and spacing will be optimized according to the material characteristics to prevent blockage and entanglement and ensure smooth transportation. Some designs will also combine the extrusion dehydration function to perform preliminary solid-liquid separation of kitchen waste while conveying.

Discharging hopper and crushing: In order to better handle kitchen waste, the front end of the conveyor is often equipped with a discharging hopper, and the bottom of the discharging hopper can be conveyed with a double screw to reduce blockage, increase conveying capacity, and evenly convey the garbage to the subsequent crushing equipment. Before entering the double-axis screw conveyor, the kitchen waste is usually pre-treated and coarsely crushed or crushed in two stages to reduce the particle size for subsequent transportation and processing.

Compared with a single-axis screw conveyor or other conveying methods, the double-axis structure of a double-axis screw conveyor for kitchen waste can provide a larger conveying area and thrust, and more effectively convey kitchen waste with high viscosity and high moisture content. The interaction of the two screw shafts helps to break up and turn over the materials, reducing the blockage caused by entanglement and adhesion of the materials during transportation, especially for kitchen waste containing long fibers or plastic bags.

The coordinated work of the two shafts can convey materials more evenly, which is conducive to the stable operation of subsequent processing equipment. Through special blade design and extrusion, some double-axis screw conveyors can perform preliminary extrusion and dehydration of kitchen waste while conveying, reducing the moisture content. It helps to control the spread of odor and reduce environmental pollution.

Double-axis screw conveyors for kitchen waste are widely used in various types of kitchen waste treatment systems, such as the kitchen waste treatment line of the garbage treatment center, to transport a large amount of collected kitchen waste for subsequent centralized treatment and resource recycling. In residential areas or community waste treatment facilities, it can be used to transport kitchen waste from residents from collection points to waste treatment equipment or trash cans, so as to achieve orderly collection and transportation of kitchen waste in the community. The equipment can transport kitchen waste to composting equipment for composting, provide a stable material supply for the composting process, and promote the resource utilization of kitchen waste.

In short, the kitchen waste double-axis screw conveyor is an important link equipment in the kitchen waste treatment line. Through the synergistic effect of the double axes, it solves the problem of easy blockage and low treatment efficiency of traditional single-axis equipment. It is one of the key equipment for the resource treatment of kitchen waste. When selecting, it is necessary to combine the material characteristics, processing scale and process requirements, and pay attention to the anti-corrosion and wear resistance of the equipment to ensure long-term stable operation.

Address:China,Yanjin county forest park gate to the west 1000 meters north road.