Plastic pellets Auger Conveyor is an automated conveying equipment designed for various plastic pellets such as PE, PP, PVC, and ABS. Based on the core principle of rotating screw blades for propulsion, it has become an indispensable key link in the plastic processing industry chain due to its outstanding advantages such as anti-clogging, wear resistance, and strong adaptability. It can achieve continuous transfer of plastic pellets from raw material silos and crushing workshops to extruders, injection molding machines, granulators, and other equipment. Considering the characteristics of plastic pellets, such as uneven hardness, easy dust generation, and the need to avoid secondary pollution, the equipment has been comprehensively optimized in its structural design. The single unit length can reach 30 meters, and the conveying speed can be adjusted according to the feeding requirements of downstream equipment, achieving controllable conveying from tens of kilograms to tens of tons per hour.

Based on structural form and application scenarios, Plastic Pellets Auger Conveyors are divided into three core types: tubular, U-shaped, and flexible hose type. All are adapted to the conveying characteristics of plastic pellets, with different emphasis on airtightness, flexibility, and ease of maintenance.

Tubular Screw Conveyor: Features a fully enclosed tubular structure with a shafted screw design, offering excellent sealing to effectively prevent dust leakage and contamination of plastic pellets. It is suitable for long-distance, high-volume horizontal or slightly inclined conveying of clean new materials such as PE and PP.

U-shaped Screw Conveyor: Uses an open U-shaped trough with a removable sealing cover, balancing enclosed conveying and ease of maintenance. The trough can be fitted with wear-resistant liners, suitable for conveying recycled plastic pellets and crushed materials.

Flexible Hose Screw Conveyor: Uses a flexible hose as the conveying channel, coupled with bendable screw blades, offering strong spatial adaptability. It can achieve multi-angle and curved conveying, suitable for injection molding workshops with narrow spaces and complex layouts.

The Plastic Pellets Auger Conveyor uses fully enclosed pipe conveying, completely eliminating dust pollution and material loss. It supports variable frequency speed control and automated linkage control, achieving accurate feeding and seamless integration with upstream and downstream equipment.

Continuous and Uniform Feeding: The screw mechanical propulsion method ensures stable and continuous conveying of plastic pellets without pulsation or flow interruption, meeting the stringent requirements for consistent feeding in automated production lines. Adaptable to various materials: Whether it's free-flowing virgin materials, irregularly shaped recycled materials, or color masterbatches prone to static electricity, reliable conveying can be achieved by adjusting the screw design.

Fully enclosed design: The pipes or troughs are completely sealed, completely eliminating dust leakage and external impurity intrusion, maintaining a clean production environment, and preventing material contamination.

Flexible multi-directional layout: Supports horizontal, inclined, vertical, or curved layouts, easily adapting to complex workshop layouts.

Modular customization: The inlet/outlet positions can be customized according to process requirements, and roller designs and explosion-proof motors can be added. Multi-point feeding and discharging can be implemented based on your site conditions.

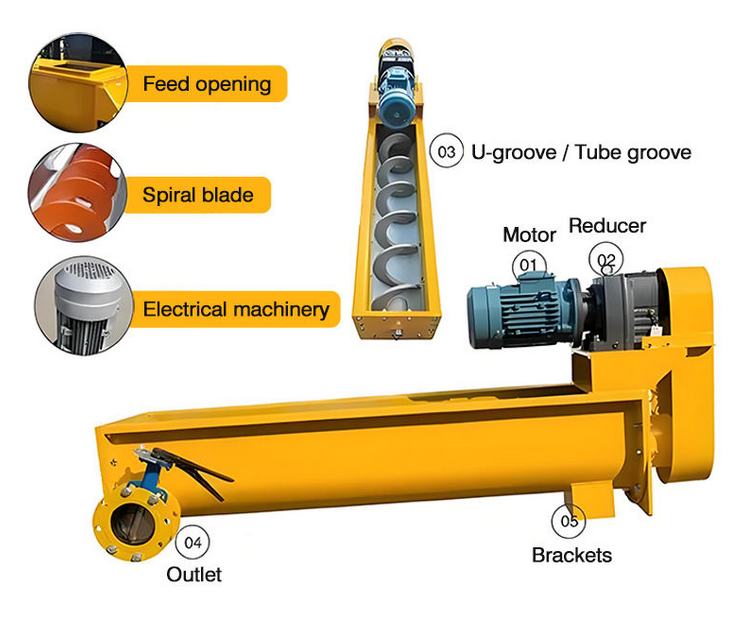

The Plastic Pellets Auger Conveyor is mainly composed of five core components, which work together to ensure stable conveying of plastic pellets.

Conveying body: This is the core working unit of the equipment, and the structure varies depending on the model. The tubular model uses a sealed circular tube, the U-shaped model uses an open U-shaped trough + removable sealing cover, and the flexible hose model uses a flexible wear-resistant hose.

Drive system: Composed of a motor, reducer, and coupling, it provides power for conveying. The motor mostly uses a variable frequency speed control motor, which can accurately adjust the speed to control the conveying volume; the reducer reduces the speed and increases the torque to meet the pushing requirements of plastic pellets.

Inlet and outlet devices: Including the inlet and outlet ports, the inlet port is mostly square or circular and can be connected to silos and hoppers; the outlet port position can be adjusted as needed to connect to downstream equipment such as injection molding machines and extruders.

Support and fixing components: Tubular and U-shaped models are equipped with fixed brackets or bases to ensure the stability of the equipment during operation; the flexible hose model is equipped with movable brackets and universal wheels for flexible position adjustment.

Auxiliary components: Depending on the working conditions, wear-resistant liners, dust-proof seals, cleaning ports, etc. can be selected to further optimize equipment performance.

The Plastic Pellets Auger Conveyor operates based on the principle of screw propulsion. The core mechanism involves a drive system that rotates a spiral blade. The friction between the blade and the plastic pellets, the thrust from the spiral surface of the blade, and the counter-friction between the pellets and the inner wall of the conveyor body propel the plastic pellets continuously forward along the conveying direction. When the motor outputs a stable torque through the reducer and drives the spiral blade to rotate via a coupling, the plastic pellets enter the conveyor body from the inlet, move smoothly along the spiral pitch direction under the propulsion of the rotating blade, and are finally discharged precisely from the outlet.

| Model |

Diameter (mm) |

Pitch (mm) |

Rotating speed (r/min) |

Capacity (m³/h) |

Rotating speed (r/min) |

Capacity (m³/h) |

Rotating speed (r/min) |

Capacity (m³/h) |

Rotating speed (r/min) |

Capacity (m³/h) |

|

| Small | 100 | 100 | 100 | 140 | 2.2 | 112 | 1.7 | 90 | 1.4 | 71 | 1.1 |

| 125 | 125 | 125 | 125 | 3.8 | 100 | 3 | 80 | 2.4 | 63 | 1.9 | |

| 160 | 160 | 160 | 112 | 7.1 | 90 | 5.7 | 71 | 4.5 | 56 | 3.6 | |

| 200 | 200 | 200 | 100 | 12.4 | 80 | 9.9 | 63 | 7.8 | 50 | 6.2 | |

| Small | 250 | 250 | 250 | 90 | 21.8 | 71 | 17.2 | 56 | 13.6 | 45 | 10.9 |

| 315 | 315 | 315 | 80 | 38.8 | 63 | 30.5 | 50 | 24.2 | 40 | 13.4 | |

| 400 | 400 | 355 | 71 | 62.5 | 56 | 49.3 | 45 | 38.6 | 36 | 31.7 | |

| Large | 500 | 500 | 400 | 63 | 97.7 | 50 | 77.6 | 40 | 62 | 32 | 49.6 |

| 630 | 630 | 450 | 50 | 138.5 | 40 | 110.8 | 32 | 88.6 | 25 | 69.3 | |

| 800 | 800 | 500 | 40 | 198.5 | 32 | 158.8 | 25 | 124.1 | 20 | 99.3 | |

We provide tailored solutions for customers in various fields, including injection molding automation, modified granulation, and recycling. Whether solving the wear-resistant conveying challenges of glass fiber reinforced materials or achieving pollution-free, rapid material changeover in multi-color masterbatch production lines, our customized equipment features superior sealing, wear-resistant design, and intelligent control.

An injection molding plant with 12 injection molding machines previously used manual feeding to convey ABS plastic pellets, resulting in uneven feeding, raw material waste, and high labor costs. They customized multiple mobile flexible hose screw conveyors with 120mm pipe diameters, each corresponding to one injection molding machine. The inlet connects to the raw material ton bag hopper, and the outlet connects to the injection molding machine hopper. The equipment is equipped with casters for flexible positioning, completely replacing manual feeding and reducing the number of feeding workers by 8.

PET plastic recycling: Crushed and washed PET sheets need to be conveyed to a granulator, and then the finished recycled granules are transferred to a storage silo. Previously, belt conveyors were used, which suffered from problems such as sheet adhesion and blockage, significant granule loss, and easy contamination of impurities. A customized U-shaped + tubular combined screw conveyor system was developed. The U-shaped model is used to convey moist PET sheets, with a wear-resistant liner and a removable cover for easy cleaning of residues. The tubular model is used for transferring finished granules, employing a fully enclosed stainless steel structure to prevent impurities from entering. The entire system operates automatically, requiring only one operator to monitor, significantly reducing operating and maintenance costs.

Dust-free EVA granule conveying: EVA plastic granules need to be conveyed to the mixer and shoe sole pressing machine. EVA granules are lightweight and easily pulverized. Previously, pneumatic conveying resulted in severe dust generation and pipe blockage. A custom-designed 160mm diameter tubular screw conveyor was developed, featuring a fully enclosed pipe structure and anti-static coating, coupled with a forced feeding device and frequency conversion drive system. The conveying length is 20 meters, enabling continuous transfer from the raw material silo to the mixer and pressing machine. Sealed dustproof components are installed at the inlet and outlet of the equipment to prevent dust leakage and granule residue.

The Plastic Pellets Auger Conveyor integrates multiple systems, including PLC, to monitor conveying volume and equipment status in real time, enabling remote start/stop, fault warning, and automatic adjustment. Its core value lies in seamless linkage with upstream material silos and downstream mixing and molding equipment.

Precise Metering and Linkage: Variable frequency speed control precisely controls the feeding volume and can be linked with loss-in-weight scales and mixers to achieve automatic batching.

Centralized Control: Connected to the factory's central control system for remote start/stop, status monitoring, and fault alarms.

Multi-point, Multi-directional Conveying: One main unit can supply materials to multiple downstream devices or retrieve materials from multiple silos through switching valves, enabling flexible production.

Dahan Machinery has its own production workshop and R&D team, eliminating intermediaries and offering excellent cost-effectiveness. We specialize in customized Plastic Pellets Auger Conveyor production, offering tubular, U-shaped, and flexible hose models to meet the needs of various industries such as injection molding, plastic recycling, and shoemaking. Our equipment perfectly matches material characteristics and site layout. We can customize equipment to achieve precise multi-machine feeding, stable conveying of recycled granules, and dust-free transfer of EVA pellets, significantly reducing costs and increasing efficiency. We provide solution design and manufacturing drawings, and can customize suitable conveying equipment based on your specific conveying needs.

With its comprehensive advantages of stability, airtightness, flexibility, economy, and intelligence, the Plastic Pellets Auger Conveyor not only solves common pain points in plastic pellet conveying but also, through high customization and intelligence, becomes a key infrastructure for improving plastic production efficiency, quality, and competitiveness.

Address:China,Yanjin county forest park gate to the west 1000 meters north road.