Sediment, as a complex mixture of solid particles of various particle sizes (including sand, silt, clay, etc.) mixed with water, usually has the characteristics of high water content, uneven particle composition, and easy compaction. In view of these characteristics, the sediment linear vibrating screen uses the linear vibration generated by the exciter to make the sediment do parabolic motion on the inclined screen surface, thereby achieving the separation of particles of different particle sizes and the preliminary removal of water.

Usually, coarse sand can use a 10-20 mesh screen, while for fine sand, a 40-80 mesh screen is recommended, and even more than 80 mesh can be used in certain cases. This flexible mesh selection enables the sand linear vibrating screen to meet different process requirements and ensure product quality and production efficiency.

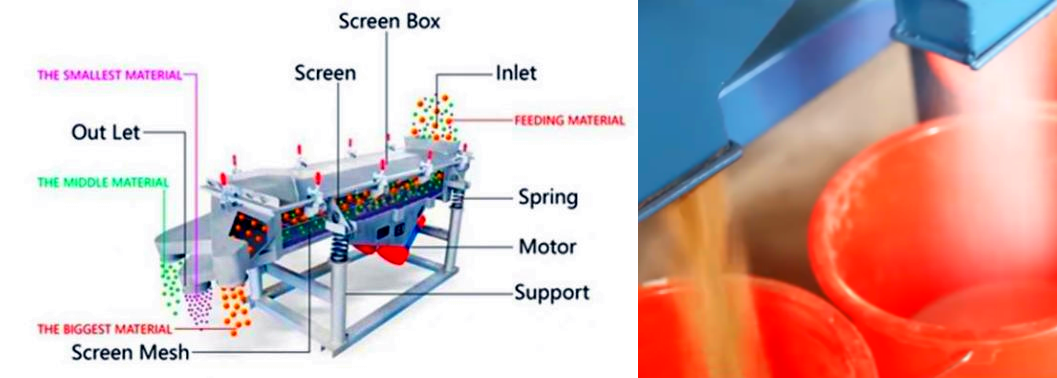

The screen uses the synchronous reverse excitation force generated by two vibrating motors to make the screen box produce strong linear reciprocating vibrations. The material is continuously thrown up and jumped forward on the screen surface to achieve screening and transportation. The core lies in the multi-layer inclined screen:

The upper screen (coarse screen 10-20 mesh): The aperture is large, and the primary task is to quickly separate large particles of impurities (such as stones, shells, garbage) in the sand or to perform preliminary coarse sand classification.

The middle screen (middle screen 20-40 mesh): The aperture is moderate, responsible for screening out medium-sized sand particles (such as construction sand) that meet the requirements.

Lower screen (fine screen/dewatering screen 40-80 mesh): with the smallest aperture, used to separate fine sand, silt or silt, and use vibration to assist dehydration, discharge muddy water or fine particles.

This step-by-step screening structure can effectively overcome the problem of easy blockage of silt and high viscosity when containing water. The high-frequency and low-amplitude vibration method helps to break up slight agglomerates, improve the screening rate and reduce the blockage of the screen holes. It is widely used in river dredging, sand production lines, sand and gravel aggregate cleaning and grading, soil remediation, sludge screening in sewage treatment plants, and precise particle size grading, dehydration and impurity removal of silt materials in the fields of building materials and chemical industry.

|

Features |

Linear vibrating screen for sediment |

Circular vibrating screen |

|

Picture |

|

|

|

Movement trajectory |

The material moves along a straight parabolic trajectory, suitable for the smooth transportation of fine particles |

The material moves in a circular or elliptical shape, and the centrifugal force enhances the dispersion of the material |

|

Screening efficiency and applicable particle size |

The screening particle size range is usually 0.074-5mm, and the classification efficiency of fine powder and micro powder materials is high |

Good at handling large-particle and high-density materials, such as ore and sand, and the throwing movement reduces the risk of clogging |

|

Anti-clogging ability |

The material movement trajectory is smooth and easy to clog, and a net cleaning device needs to be installed |

Throwing The throwing trajectory makes the material bounce strongly and automatically cleans the screen holes, which is suitable for difficult-to-screen or sticky materials. |

|

Screening efficiency |

Suitable for large particles and high-viscosity sediment, with high screening efficiency and large output |

More suitable for fine screening of fine particles, with low efficiency and easy clogging when processing high-viscosity sediment |

|

Application scenarios |

Suitable for coarse and medium screening of bulk materials such as sediment, sand and gravel, widely used in mining and construction industries |

Suitable for fine screening in chemical, food and other industries, with poor adaptability to high humidity and sticky sediment |

The working principle of the linear vibrating screen for sediment is mainly based on vibration separation technology.

Vibration mechanism: The equipment generates vibration through a vibration motor or exciter to form a linear vibration. This vibration causes the screen to move continuously in the horizontal direction, thereby pushing the material to move on the screen surface.

Material stratification: When the material moves on the screen surface, smaller particles will fall through the pores of the screen, while larger particles will continue to move on the screen surface. Due to the uniform force generated by the linear vibration, the material is stratified on the surface of the screen, thereby achieving effective screening.

Material collection: After screening, the separated materials are discharged from different outlets. Qualified fine-grained materials fall into the collection tank below through the screen, while the unscreened coarse particles continue to move forward and are eventually discharged.

The sediment linear vibrating screen is widely used in mining, construction, environmental protection and other fields, mainly used to separate solid particles of different particle sizes. In mining, it is used to screen sand, ore and fine-grained materials to ensure the uniformity and quality of raw materials. For example, in the sand and gravel production line, the linear vibrating screen can effectively remove impurities and screen out finished sand that meets the specifications, thereby improving production efficiency and product quality. In the construction industry, the linear vibrating screen can be used to process concrete aggregates to ensure that the particle size of the aggregates meets the design requirements, thereby improving the strength and durability of the concrete.

In addition, the sediment linear vibrating screen also plays an important role in the field of environmental protection. It can be used for waste treatment and sewage treatment to help separate recyclables and non-recyclables in solid waste. In sewage treatment plants, linear vibrating screens can efficiently remove sediments and improve water quality.

The price of the sediment linear vibrating screen varies depending on the brand, model, specification and configuration. Generally speaking, the price range of the linear vibrating screen for sediment on the market is roughly from several thousand yuan to tens of thousands of yuan.

Different processing capacity and screening area will affect the price. Large equipment is usually more expensive. Equipment using highly wear-resistant materials and advanced manufacturing processes is usually more expensive. Additional features such as automatic control systems and special screen designs will increase the cost of the equipment.

For example, the price of some high-frequency dewatering screens may be between 10,000 yuan and 30,000 yuan, while the price of ordinary linear vibrating screens may be between several thousand yuan and 10,000 yuan. The specific price still needs to be consulted according to actual needs and market conditions.

Sediment linear vibrating screen has efficient and accurate screening capabilities when processing materials of various particle sizes, and is widely used in mining, construction and other fields. Using its unique linear vibration method, it effectively overcomes the screening difficulties caused by the high moisture content and easy compaction of sediment, and realizes efficient treatment and classification of sediment.Address:China,Yanjin county forest park gate to the west 1000 meters north road.