Silicon Micro Powder Screw Conveyor is a feeding device for transferring silicon micropowder from one location to another. A single unit can transfer the powder over a distance of up to 30 meters. For ultra-long-distance conveying, multiple units can be connected in series. Customization is available, allowing adjustment of machine specifications, conveying angle, and speed according to site conditions. It also supports the addition of rollers for flexible movement and easy relocation, adapting to diverse needs such as multi-station workshops and temporary transfers.

The Silicon Micro Powder Screw Conveyor is optimized for the characteristics of silicon micro powder, offering advantages such as a sealed, dust-free environment, stable conveying, and minimal clogging and bridging. Its compact structure and small footprint allow for adaptability to various conveying scenarios and multi-device联动 (interconnection/coordination), ensuring reliable operation, low energy consumption, and easy maintenance.

Strong Sealing: The cylinder employs a seamless welding process, with soft-seal flanges at the inlet and outlet. The machine supports the addition of dust covers, effectively preventing dust generation from ultrafine silicon micro powder particles and reducing silicon micro powder loss.

Anti-Clogging Design: Equipped with a variable frequency motor, the conveying speed can be adjusted according to the silicon micro powder feed rate, preventing material accumulation inside the cylinder. The bearings feature a dustproof seal structure to prevent silicon micro powder particles from entering and causing wear and jamming.

Long-Distance Conveying:A single unit can achieve conveying distances up to 30 meters, eliminating the need for multiple units and reducing installation costs and floor space. It is suitable for large-scale material handling needs in workshops, warehouses, and other similar settings.

Long-Distance Conveying:A single unit can convey materials up to 30 meters long without the need for multiple units, reducing installation costs and floor space requirements. Non-standard customization: Models can be customized according to site conditions, conveying volume, and installation angle. Roller designs are also supported for flexible equipment movement and quick relocation, adapting to diverse needs such as multi-station operations and temporary transfers.

Considering the ultra-fine and dust-prone characteristics of silicon micro powder, our factory offers three types of screw conveyors: tubular screw conveyors, inclined screw feeders, and flexible hose screw conveyors. Each model has its own structural advantages and can adapt to different silicon micro powder transfer scenarios.

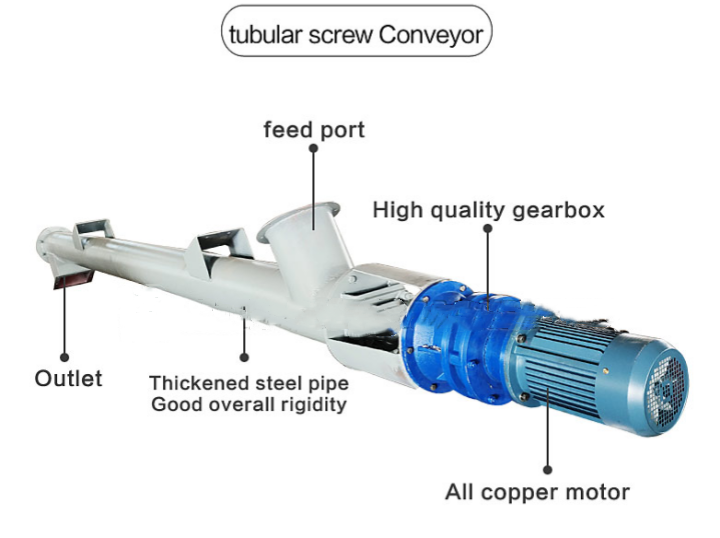

Tubular Screw Conveyor: This is the mainstream model for conveying silicon micro powder. It adopts a fully enclosed, seamless welded tubular body, eliminating silicon micro powder dust and leakage at the source. Available in carbon steel, stainless steel, and PP materials, it is suitable for long-term, large-scale, fixed-path silicon micro powder transfer from fixed workstations in workshops, warehouses, to production lines.

Inclined Screw Feeder: This can lift silicon micro powder from a low position to a high position and feed it quickly. Supporting 30°-60° conveying, this machine can lift and convey silicon micropowder within limited space. It is particularly suitable for high-level feeding of equipment such as mixers, packaging machines, and reactors.

Hose Screw Conveyor: Made of flexible hose, this conveyor can bend and bypass obstacles, enabling curved conveying in three-dimensional space and solving conveying challenges in complex layouts. For silicon micropowder conveying, the fully enclosed nature of the hose ensures dust-free operation. More importantly, this model is typically designed to be lightweight and easy to move, making it ideal for laboratories, multi-feeding-point systems, or production line adjustments.

The Silicon Micro Powder Screw Conveyor mainly consists of a drive unit, screw shaft, conveyor housing, inlet/outlet ports, and sealing components. These components work together to complete material conveying. The overall structure is compact, featuring specialized blades and dustproof seals, adapted to the characteristics of silicon micropowder, balancing conveying stability and airtightness.

Drive Unit: Consists of a motor, reducer, and coupling. Its core task is to provide stable and reliable power and control the rotational speed of the screw shaft. Considering the characteristics of silicon micropowder, it is often equipped with a variable frequency motor to achieve stepless and linear adjustment of the conveying capacity, meeting the requirements of refined process control.

Screw: This consists of a screw shaft and screw blades. The screw shaft is usually a high-strength hollow steel tube to ensure torsional rigidity during long-distance conveying. The screw blades are the propulsion components that directly contact the silicon micropowder; their material, pitch, and thickness are specially designed to minimize compaction and shearing of the ultrafine powder while ensuring pushing efficiency.

Trough: This is the outer shell that holds the screw and silicon micropowder. Depending on the model, it can be a U-shaped trough, a circular tube, or a flexible hose. Its core requirements are extremely high sealing and smooth inner walls. Good sealing prevents dust leakage and external contamination.

Inlet/Outlet: These two components are the interfaces between the material flow and external equipment. They need to be custom-made according to the connection methods of upstream and downstream equipment to ensure interface matching and no leakage. The feed inlet is typically equipped with a regulating device or valve to control the feed rate; the discharge port design must consider the smooth discharge of materials.

When the drive unit rotates the screw shaft, the helical blades mounted on the shaft rotate accordingly. After the silicon micropowder falls into the tank from the feed inlet, it is placed between the rotating blades. Utilizing the combined action of the silicon micropowder's own gravity, friction with the tank wall, and the cohesive force between the particles, the silicon micropowder is axially propelled forward along the tank wall by the blades until the material is stably and dust-free discharged from the discharge port at the other end.

| Model |

Diameter (mm) |

Pitch (mm) |

Rotating speed (r/min) |

Capacity (m³/h) |

Rotating speed (r/min) |

Capacity (m³/h) |

Rotating speed (r/min) |

Capacity (m³/h) |

Rotating speed (r/min) |

Capacity (m³/h) |

|

| Small | 100 | 100 | 100 | 140 | 2.2 | 112 | 1.7 | 90 | 1.4 | 71 | 1.1 |

| 125 | 125 | 125 | 125 | 3.8 | 100 | 3 | 80 | 2.4 | 63 | 1.9 | |

| 160 | 160 | 160 | 112 | 7.1 | 90 | 5.7 | 71 | 4.5 | 56 | 3.6 | |

| 200 | 200 | 200 | 100 | 12.4 | 80 | 9.9 | 63 | 7.8 | 50 | 6.2 | |

| Small | 250 | 250 | 250 | 90 | 21.8 | 71 | 17.2 | 56 | 13.6 | 45 | 10.9 |

| 315 | 315 | 315 | 80 | 38.8 | 63 | 30.5 | 50 | 24.2 | 40 | 13.4 | |

| 400 | 400 | 355 | 71 | 62.5 | 56 | 49.3 | 45 | 38.6 | 36 | 31.7 | |

| Large | 500 | 500 | 400 | 63 | 97.7 | 50 | 77.6 | 40 | 62 | 32 | 49.6 |

| 630 | 630 | 450 | 50 | 138.5 | 40 | 110.8 | 32 | 88.6 | 25 | 69.3 | |

| 800 | 800 | 500 | 40 | 198.5 | 32 | 158.8 | 25 | 124.1 | 20 | 99.3 | |

Our factory customizes conveying solutions for different production capacities and processes, stably matching mixing, screening, and packaging equipment, effectively solving problems such as material blockage and dust leakage, facilitating the automation upgrade of production lines, and gaining recognition from numerous industry customers.

Customized Silicon Micropowder Production and Conveying: The client primarily produces photovoltaic-grade ultrafine silicon micropowder. Previously, their conveying process suffered from severe dust pollution and inconvenient movement, making it unsuitable for temporary transfers at multiple workstations. Our factory customized multiple tubular silicon micropowder screw conveyors for them, each 15 meters long, with a roller base design, allowing for flexible switching between production workshops and storage areas. The fully enclosed seamless welded cylinder and double-sealed structure eliminate silicon micropowder dust.

Large-Scale Conveying for Chemical Enterprises: This company focuses on deep processing of silicon micropowder and requires continuous conveying from the outlet of an ultrafine vertical mill to the finished product tank. They needed a single machine for long-distance conveying and adaptability to corrosive conditions to avoid material contamination. We customized a 30-meter ultra-long single-unit tubular screw conveyor for them, made of 316L stainless steel to extend the equipment's service life. The equipment integrates the entire process of grinding, conveying, and storage, adapting to high-flow-rate conveying needs of 30 tons per hour. The fully enclosed conveying system eliminates leakage, solving the problem of purity degradation caused by contact with external elements.

Flexible material handling for building materials companies: A client needed a silicon micropowder preparation production line that could handle both long-distance transport at fixed workstations and temporary material replenishment. Previous equipment had poor compatibility, and powder splashing was common during inclined transport. A customized modular silicon micropowder screw conveyor was developed, consisting of two 20-meter fixed tubular models and one movable flexible hose model. The fixed models handle long-distance horizontal transport from the raw material silo to the processing workshop, while the flexible hose model, equipped with a foldable hose and roller base, adapts to temporary material replenishment scenarios between multiple equipment units and allows for easy adjustment of the transport angle.

Yes, it can. However, considering the lightweight, easily arched, and highly fluid characteristics of silicon micropowder, the maximum effective transport height of the Silicon Micro Powder Screw Conveyor is 5 meters. If the actual installation and usage height exceeds 5 meters, problems such as insufficient material filling rate, weak screw blade pushing, and powder suspension and backflow will occur, ultimately leading to failures such as non-feeding, material blockage, and a sudden drop in transport volume, making stable transport operations impossible. Within a vertical conveying range of up to 5 meters, the equipment is adaptable to the dry, fine powder properties of silicon micropowder. With a suitable screw speed and feeding structure, it ensures continuous and stable feeding.

The Silicon Micro Powder Screw Conveyor can be integrated with various powder processing equipment, connecting to core equipment such as mixers, screening machines, and packaging machines. It achieves seamless integration of the entire process from feeding, screening, mixing, to packaging, adapting to various silicon micropowder processing requirements.

Mixer: The silicon micropowder screw conveyor receives the raw silicon micropowder material from the front end and continuously and evenly transports the material to the mixer inlet through a closed screw structure, avoiding dust leakage and uneven feeding problems caused by manual feeding. It can adjust the conveying rate according to the mixing rhythm and formula ratio of the mixer to achieve continuous conveying.

Packaging Machine: In the finished silicon micropowder packaging process, the screw conveyor acts as a feeding buffer device for the packaging machine, stably transporting the processed silicon micropowder to the packaging machine's hopper, maintaining a constant material level within the hopper, and preventing packaging weighing deviations, bag clamping, and empty packages caused by intermittent feeding.

Screwing Machine: The silicon micropowder screw conveyor can connect to a screening machine to complete the feeding and post-screening material transfer. On one hand, it can uniformly feed the raw powder to be screened into the screening machine's feed end, ensuring that the material is evenly spread on the screen surface, improving screening accuracy and efficiency. On the other hand, it can classify and transport the qualified fine powder and the coarse material after screening, conveying the qualified silicon micropowder to the next process, while the coarse material is returned for reprocessing, forming a screening circulation system.

When selecting a Silicon Micro Powder Screw Conveyor, we need to consider the lightweight, dust-prone, and bridging characteristics of the material. We must comprehensively consider the conveying method, distance, and output to determine the appropriate model. A sealed, wear-resistant structure is preferred, and the sealing, materials, and operating conditions must be matched to ensure stable conveying.

Selecting based on the conveying method: Determine the horizontal, inclined, or vertical conveying method based on the site layout. For compact spaces, prioritize small trough or tubular screw conveyors. For long distances and winding sections, consider multi-section splicing or combined arrangements.

Determining the pipe diameter based on the conveying capacity: Calculate the hourly conveying capacity and conveying distance to determine the screw diameter, pipe diameter, and drive motor power. This avoids insufficient material supply due to an undersized model or energy waste due to an oversized model.

Selecting the material based on requirements: Carbon steel is sufficient for conventional silicon micro powder conveying to control costs; for cleanliness, pollution prevention, or slightly corrosive conditions, 304/316 stainless steel is recommended; consider the abrasiveness of the silicon micro powder particles.

Selection based on production line requirements: The selection should consider the interface dimensions and feeding rhythm of front-end screening, intermediate mixing, and back-end packaging equipment to ensure smooth material flow. For automated production lines, variable frequency control, material level sensing, and interlocking start/stop functions can be selected.

Dahan Machinery, addressing the lightweight, dust-prone, and bridging characteristics of silicon micro powder, employs a fully enclosed tubular structure with customized spiral blades and sealing components. It is suitable for horizontal, inclined, and short-distance vertical conveying, and can stably connect to mixers, screening machines, packaging machines, and other equipment. We have standardized production lines and a strict quality control system, providing one-stop service including customized solutions, drawings, and after-sales parts.

The Silicon Micro Powder Screw Conveyor is a core component of powder conveying equipment, adaptable to short-distance vertical, horizontal, and inclined conveying, and stably connected to mixing, screening, and packaging processes.

Address:China,Yanjin county forest park gate to the west 1000 meters north road.