Ultrasonic Sieves are screening devices that combine high-frequency ultrasonic cleaning technology with the principle of traditional vibrating sieving. They primarily address the pain points of agglomeration, screen clogging, and low efficiency in the screening of fine and micro powders. Through the synergistic action of a 38kHz high-frequency ultrasonic system and a vibrating motor, they utilize mechanical vibration to achieve three-dimensional material movement and grading, while the high-frequency micro-amplitude vibration of the ultrasonic waves breaks up electrostatic agglomerations, cleaning the screen apertures in real time. This fundamentally improves screening accuracy and efficiency. Single-layer ultrasonic system additions are supported, solving the screen clogging problem and reducing procurement costs.

Ultrasonic Sieves are available in three materials: carbon steel, stainless steel, and PP. The carbon steel version is suitable for general industrial applications, the stainless steel version meets hygiene standards for the food and pharmaceutical industries, and the PP version is suitable for screening corrosive materials. The maximum screening mesh size is 1800 mesh, meeting the grading requirements of ultra-fine powders. The maximum screen diameter is 2 meters, suitable for different production capacity scenarios from small-batch experiments to large-scale mass production. Meanwhile, the equipment supports comprehensive non-standard customization. Hoppers can be added according to the user's actual needs, and the position, shape, and size of the inlet and outlet can be flexibly modified to precisely match various complex working conditions, providing personalized screening solutions for customers in different industries.

Based on different structural designs and application scenarios, our factory mainly produces three categories of Ultrasonic Sieves: ultrasonic rotary vibrating screens, ultrasonic test sieves, and ultrasonic swing screens. Each model combines unique structures with screening principles to adapt to different production and experimental needs.

Ultrasonic Rotary Vibrating Screen: This design combines a vertical vibrating motor with an ultrasonic system. The equipment generates three-dimensional vibration through the vibrating motor, causing the material to move in a spiral motion on the screen surface. Combined with high-frequency ultrasonic cleaning, grading is achieved. The screen diameter is mostly 800-2000mm, supporting 1-6 layers of screen configurations. It can complete the separation of 2-5 particle size grades in a single pass, with a processing capacity of 0.5-10t/h.

Ultrasonic Test Sieve: Designed specifically for laboratory use, this compact sieve typically has a diameter of 200-300mm, requiring minimal floor space and easily placed on a lab bench. Equipped with a precision ultrasonic system and adjustable vibration parameters, it supports ultra-fine sieving from 300-1800 mesh. The sieve uses a quick-release design for easy replacement of different mesh sizes, making it suitable for sample analysis and testing in university laboratories and corporate R&D centers.

Ultrasonic Gyratory Sieve: Combining gyratory and ultrasonic technologies, this sieve uses an eccentric shaft to generate a simulated artificial gyratory trajectory, combined with high-frequency ultrasonic cleaning. It is particularly suitable for processing highly viscous and easily agglomerated fine powder materials. The inclined sieve surface allows materials to flow along the sieve surface under the gyratory force, resulting in a longer sieving path and more thorough classification. Suitable for sieving viscous materials such as pigments, carbon black, and starch, it effectively solves the problems of screen sticking and clogging found in traditional equipment.

Ultrasonic Sieves break through the limitations of traditional screening methods with high-frequency vibration. With advantages such as anti-clogging mesh, high precision, high efficiency, and low wear, they easily handle challenges such as ultrafine powders and highly static materials.

Anti-clogging mesh: The micro-shock wave energy density generated by ultrasonic vibration reaches 0.5-2W/cm², instantly clearing 0.1-10μm particles embedded in the mesh, eliminating the need for manual mesh tapping or rubber ball cleaning, and completely eliminating the risk of secondary contamination.

High screening precision: By adjusting the ultrasonic frequency and power, the screening particle size range can be precisely controlled. All screens meet standards and are CE certified, ensuring a high pass rate.

Stable and durable operation: The ultrasonic system avoids fine powder clogging, reduces screen wear, extends service life by 2-3 times, and lowers consumable replacement costs.

Wide screening range: Due to the high screening precision of ultrasonic vibrating screens, they can handle ultrafine powders in powders, slurries, and granules, solving the screening problems of various ultrafine powders.

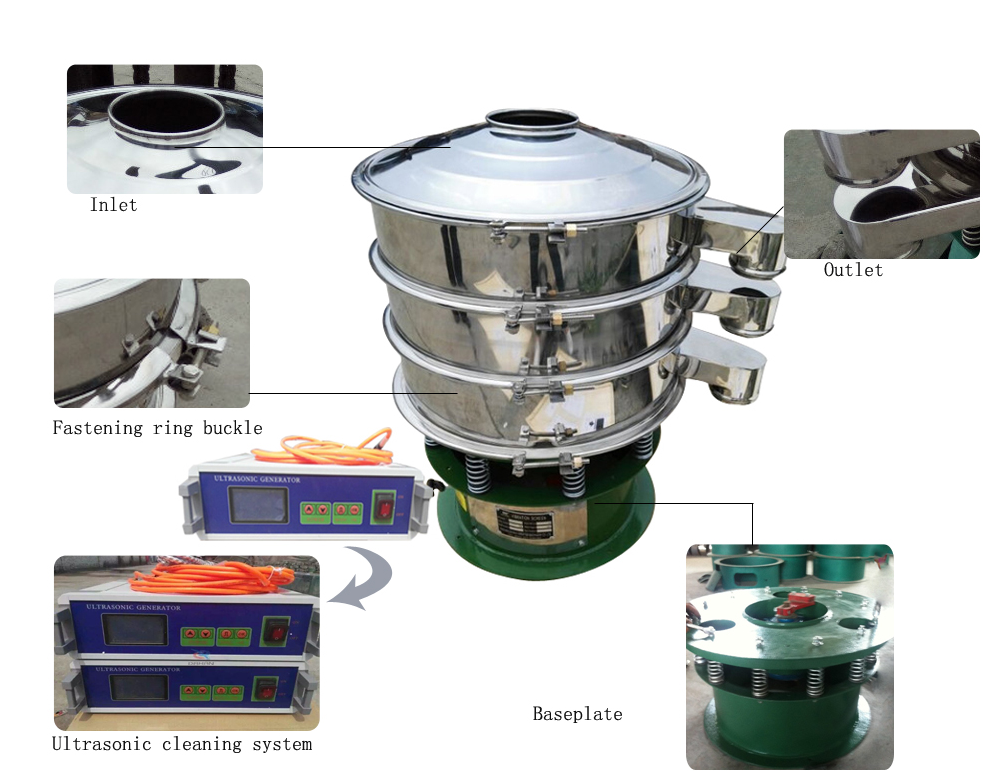

The entire screening process of an Ultrasonic Sieves is accomplished through the combined action of multiple components, including the ultrasonic system, screen, and screen frame.

Screen Body: Primarily made of 304 or 316L stainless steel, with smooth, dead-angle-free surfaces in contact with materials, meeting hygiene standards for the food and pharmaceutical industries.

Vibration Motor: Utilizes a high-quality copper wire motor, ensuring smooth operation and low noise; the ultrasonic generator and transducer feature a waterproof and dustproof design, suitable for complex conditions such as humidity and dust.

Screen: Supports customization of various mesh sizes, from 10 mesh to 1800 mesh, to meet the screening needs of different fine powders and slurries.

Screen Frame and Cover: The screen frame is constructed from rolled and welded steel plates, with retaining rings and flanges at the top and bottom for securing the screen, screen clamping ring, and other components. The screen cover is locked to the screen frame via a V-shaped sealing ring to prevent material leakage.

Ultrasonic Sieves operate on the dual principle of vibrating sieving and ultrasonic screen cleaning. The main body of the equipment is equipped with a vibrating motor, which generates a three-dimensional vibration trajectory that disperses, layers, and causes the material to fall off the screen surface, achieving particle size separation. Simultaneously, the ultrasonic system converts high-frequency electrical vibration into mechanical vibration, which is transmitted to the screen surface to create high-frequency micro-amplitude vibration. This high-frequency vibration can quickly break up the agglomeration of fine powder caused by static electricity and molecular attraction, effectively clearing clogged particles within the screen openings and fundamentally solving the problems of incomplete sieving and screen clogging associated with traditional sieving methods.

| Model |

Screen Diameter (mm) |

Sieving Area (m2) |

Screen Size (mesh) |

Layers |

Power (KW) |

| DHC-400 | 340 | 0.091 | 80-600 | 1~3 | 0.18 |

| DHC-600 | 540 | 0.229 | 0.25 | ||

| DHC-800 | 730 | 0.418 | 0.55 | ||

| DHC-1000 | 900 | 0.636 | 0.75 | ||

| DHC-1200 | 1100 | 0.95 | 1.1 | ||

| DHC-1500 | 1400 | 1.539 | 1.5 | ||

| DHC-1800 | 1700 | 2.269 | 2.2 | ||

| DHC-2000 | 1886 | 2.792 | 2.2 |

Ultrasonic Sieves, with its high-frequency vibration technology, can quickly process ultrafine powders, highly static, strongly adsorbent, and sticky materials, significantly improving sieving accuracy and output, making it a core piece of equipment for precision manufacturing.

Powdered materials: Includes 200-635 mesh nano-calcium carbonate, graphite powder, highly active powders, and easily static-prone powders, such as plastic granules and pigment powders, eliminating electrostatic adsorption, preventing screen sticking, and improving sieving accuracy.

Slurry materials: Including low-concentration slurries such as ceramic slurries and battery slurries, ultrasonic sieving simultaneously achieves solid-liquid separation and particle classification, avoiding clogging due to viscosity. Coarse particle removal rates can reach 98%. High-viscosity slurries such as rubber latexes and adhesives are separated by adjusting the ultrasonic frequency and power to reduce the impact of viscosity.

Particulate materials: Involving microparticles such as pharmaceutical microcapsules and seeds, ultrasonic sieving precisely controls particle size distribution to meet the uniformity requirements of the pharmaceutical industry. Irregular particles such as ore fragments and metal powders are separated by ultrasonic sieving, reducing jamming and improving screening efficiency.

Fiber materials: Such as chopped fibers and wood pulp fibers, ultrasonic sieving prevents fiber entanglement on the screen and simultaneously achieves fiber length classification, optimizing product performance.

Composite materials: Such as metal-ceramic composite powders and polymer-based composite materials, ultrasonic sieving enables precise separation of multi-component materials, preventing the mixing of particles of different densities or shapes and ensuring product quality stability.

The core difference between Ultrasonic Sieves and ordinary vibrating screens lies in the integration of ultrasonic screen cleaning technology. We can provide customized selection solutions based on your material characteristics, accuracy requirements, and production capacity needs.

|

Model (mm) |

Testing materials | Ordinary screening machine | UItrasonic vibrating screen | ||

| Mesh | Test results | Mesh | Test results | ||

| φ1000 | Silicon carbide | 500 | Unable to screening | 500 | 1500KG/H |

| Tungsten powder of cemented carbide | 600 | No fine powder was sifted out for 15 minutes | 600 | 30KG/H | |

| vitamin c powder | 400 | 1KG/H | 400 | 120-150KG/H | |

| φ500 | Pollen | 400 | No fine powder was sifted out for 15 minutes | 400 | Screen out 20% in 15 minutes.Fine and effective classification can be carried out in fine workmanship. |

| Nickel powder,Cobalt powder | 325 | Screen three times to meet the requirements | 400 | Screen once to meet the requirements | |

| φ450 | Ndfeb powder | 300 | 32.2% residual sieve in 30 minutes | 300 | 6.9%residual sieve in 30 minutes |

Screening Principle: Ordinary screens rely on simple mechanical vibration to classify materials. A vibrating motor generates vibrations along a specific trajectory, utilizing the material's own weight and inertia to separate it on the screen surface. Ultrasonic screens, in addition to mechanical vibration, incorporate a 38kHz high-frequency ultrasonic screen cleaning system, forming a dual effect of vibrating screening and ultrasonic agglomeration breaking. This technological upgrade allows it to handle screening problems that ordinary screens struggle with.

Different materials are suitable for different materials: Ordinary sieves are better suited for handling coarse powders or granules below 80 mesh, such as sand, feed pellets, and mineral raw materials—materials that are non-sticky and do not easily agglomerate. Ultrasonic sieves, on the other hand, focus on fine powders and micro-powders above 80 mesh, as well as special materials with high viscosity and low specific gravity, such as ultrafine powders of traditional Chinese medicine, lithium battery material powders, carbon black, and starch. Ordinary sieves are prone to agglomeration and clogging when dealing with these materials, while ultrasound can quickly break up agglomerates and clean the sieve holes.

Sieving accuracy: The sieving accuracy of ordinary sieves is typically ±3%-5%. As sieving time increases, fine powder clogging the sieve leads to a continuous decrease in accuracy. Ultrasonic sieves can improve the sieving accuracy to ±1%, enabling precise control of narrow particle size distribution.

Sieve life: In fine powder sieving, material clogging of the sieve in ordinary sieves accelerates mesh wear, resulting in frequent sieve replacements. Ultrasonic sieves clean the sieve holes in real time with ultrasound, reducing frictional wear on the sieve and extending the sieve life by 2-3 times compared to ordinary sieves.

Applicable Scenarios: Ordinary sieves are mostly used for coarse grading and preliminary impurity removal in industries such as mining, building materials, and feed, for example, sand and gravel screening and removing large impurities from raw materials. Ultrasonic sieves are widely used in fields with stringent requirements for precision and cleanliness, such as food, pharmaceuticals, chemicals, and new materials.

When selecting Ultrasonic Sieves, we need to comprehensively consider material characteristics, screening precision, production capacity requirements, equipment stability, and after-sales service. For ultrafine powders, highly static or viscous materials, priority should be given to models with mature high-frequency vibration technology and strong screen adaptability.

Screen Diameter: Select specifications such as 800-1800mm according to production scale. Smaller diameters are suitable for laboratory or small-batch production, while larger diameters are suitable for continuous industrial operations.

Screen Mesh Count: Determined based on material particle size requirements. For ultrafine screening, it is recommended to choose a screen with a mesh size of 500 or higher and to use a reinforced ultrasonic system.

Material Requirements: 316L stainless steel is preferred for the food and pharmaceutical industries, while 304 stainless steel can be selected for general chemical applications, balancing performance and cost.

Dahan Machinery's Ultrasonic Sieves utilizes a dual-source technology of mechanical vibration and ultrasonic waves to create anti-clogging screening equipment. The products are made of 304/316L stainless steel/PP material, meeting GMP standards, with a screening accuracy of ±1% and efficiency 30%-50% higher than traditional equipment. A modular customization system is built, offering free trial screening and operating condition simulation for industries such as food, pharmaceuticals, and new energy, adapting to the special material needs of starch, traditional Chinese medicine powder, rare earth powder, etc. Non-standard customization is supported, allowing for customization of the screen diameter and the position and direction of the discharge port according to your production requirements.

Ultrasonic Sieves solves the industry pain points of fine powder screening through technological innovation, providing high-quality solutions for powder processing in various fields with precise, efficient, and stable performance, helping companies improve product quality and production efficiency.

Address:China,Yanjin county forest park gate to the west 1000 meters north road.