The belt conveyor for biomass pellets is a conveying equipment designed for biomass pellets, which have the characteristics of loose accumulation, general fluidity, and susceptibility to moisture. Biomass pellets are mostly processed from agricultural and forestry wastes, with low density and irregular shape. They need to avoid damage and blockage during transportation.

The belt conveyor material is mostly made of wear-resistant and corrosion-resistant rubber or polyester materials, which can adapt to the physical properties of biomass pellets and reduce the friction loss between the material and the conveyor belt. At the same time, the belt conveyor can be designed with or horizontal conveying forms according to actual needs. The conveyor belt can be circulated by the motor to drive the roller, so as to realize the continuous conveying of biomass pellets from one place to another. It is widely used in the production, storage and transportation of biomass pellets, effectively improving the material transfer efficiency.

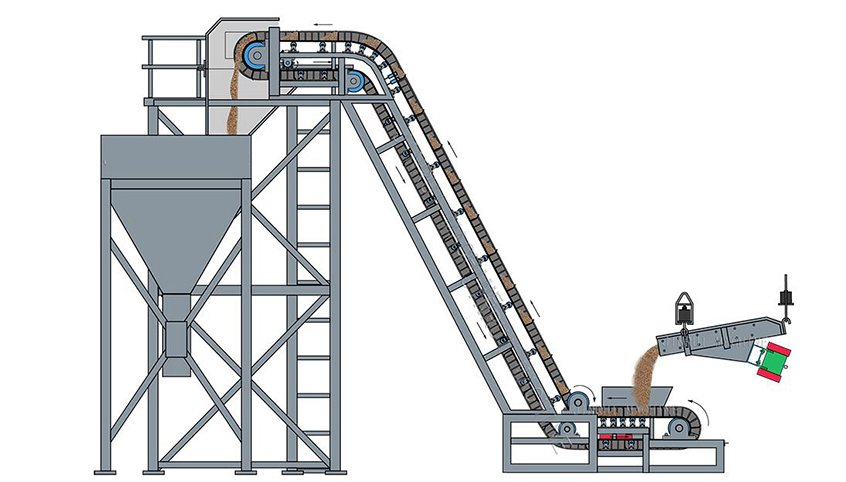

The equipment is mainly composed of a drive device, an active roller, a driven roller, a conveyor belt, an idler, a frame, etc.

During operation, the motor transmits power to the active roller through the reducer, and the active roller drives the ring conveyor belt to operate by the friction between the active roller and the conveyor belt. The biomass pellets fall evenly on the conveyor belt from the feed port and are transported forward with the movement of the conveyor belt. During the conveying process, the idler supports the weight of the conveyor belt and the material to keep the conveyor belt running smoothly; when the conveyor belt bypasses the driven roller, a closed loop path is formed to realize the continuous conveying of materials.

To deal with particle wear and conveyor belt loss: a steel cord rubber belt or a polyester canvas belt covered with a ceramic particle coating is used to withstand long-term friction with hard materials such as wood particles and rice husks. The rubber coating of the drum adopts a herringbone pattern rubber layer (thickness 8-12mm), which increases friction and reduces particle embedding wear.

Overcome the problem of easy slippage and poor fluidity of conveying: adopt a combination of corrugated ribs and transverse partitions (rib height 50-150mm, partition spacing 200-300mm), increase the tilt angle limit to 35° (ordinary flat belt is only 15°), and prevent particles from rolling and sliding. The transverse partition is made of elastic polyurethane material, which cushions the impact of particles during collision and avoids sharp angles from scratching the conveyor belt.

Biomass pellet belt conveyors play a vital role in many industries and application scenarios due to their high efficiency, stability and environmental protection. They are mainly used for large-scale, long-distance or continuous transportation of biomass pellet materials.

In biomass power plants, it is responsible for continuously conveying a large amount of biomass pellets (such as wood chip pellets, straw pellets, rice husk pellets, etc.) from the raw material yard, silo or unloading point to the feed system of the boiler combustion chamber, ensuring the stability and continuity of fuel supply, which is the key link in the efficient use of biomass fuel.

In the biomass pellet fuel production line, the belt conveyor runs through all stages of production, from the primary crushing, drying, and caching of raw materials before pelletizing, to cooling and screening after pelletizing, and finally to the storage and bagging of the final product.

For belt conveyor for biomass pellets, we are more concerned about the particle size characteristics of the biomass pellets it conveys. The particle size of biomass pellets is usually between 3.15 mm and 40 mm, and most are around 25 mm. For example, common biomass pellet fuel particle sizes are φ10×30mm or φ32×32mm. Therefore, when selecting or designing a belt conveyor for biomass pellets, the following should be considered:

The actual particle size range of the biomass pellets being transported: Ensure that the design of the belt conveyor (such as bandwidth, groove angle, skirt height, etc.) can adapt to the size of the pellets to avoid material overflow or jamming.

Material uniformity: Although the belt conveyor does not require the particle size uniformity of the pellets as high as that of pneumatic conveying, excessively different particle size distribution may still affect the conveying efficiency and equipment wear.

In short, the belt conveyor for biomass pellets is an ideal choice for efficient and safe transportation of biomass pellets. It not only ensures the continuous and stable transportation of biomass pellets, but also reduces the frequency of manual intervention. It is a key equipment in the biomass energy industry chain that connects pretreatment, molding, storage and other links.

Address:China,Yanjin county forest park gate to the west 1000 meters north road.