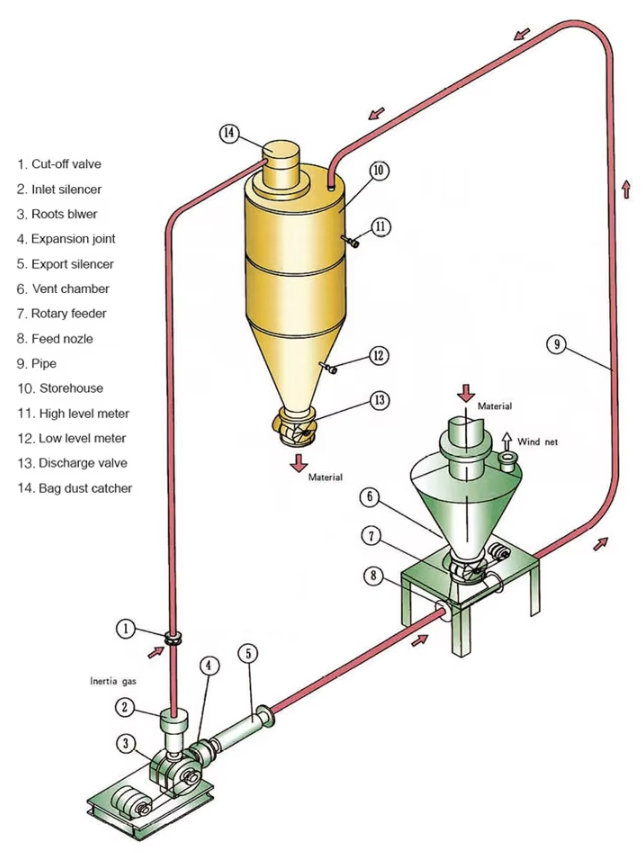

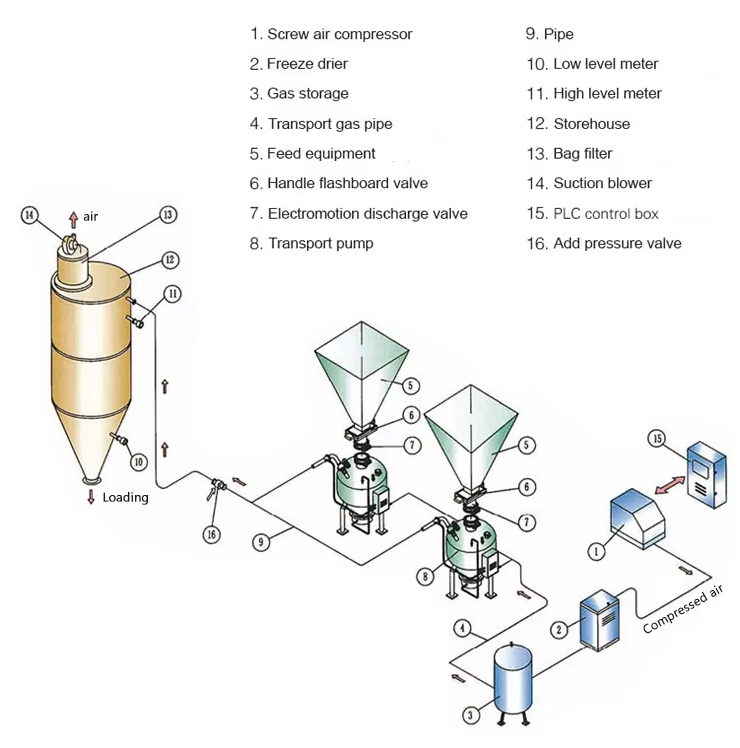

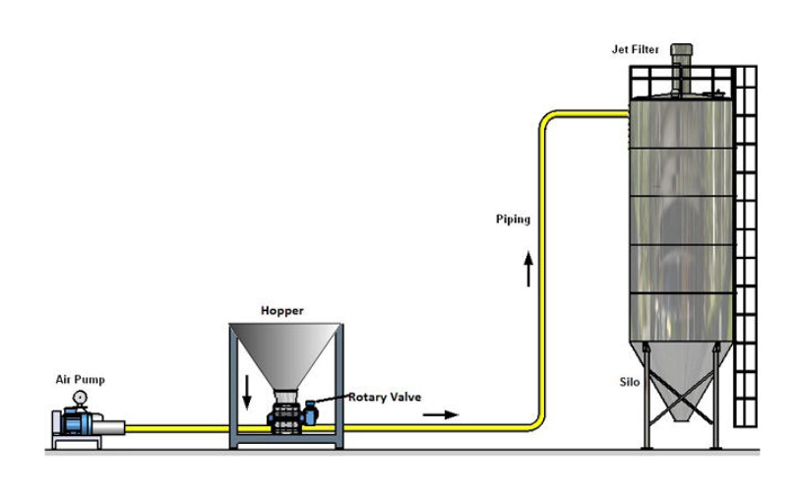

The vacuum loaders are designed for clean transfer of powder, granular or liquid materials in a closed state. It sucks materials from the original storage location such as bins and hoppers through the vacuum negative pressure principle, and delivers them to the target container through a sealed conveying pipe. The entire conveying process does not require manual intervention, which not only improves the conveying efficiency, but also greatly reduces the risk of dust leakage and cross contamination. The equipment supports a variety of configurations, such as open feed hoppers or fully enclosed storage systems, which can be flexibly adapted to different production processes.

In practical applications, vacuum loaders are often used in automated production lines that require high precision and continuity. They can accurately control the amount of material delivered each time, and realize quantitative feeding or automatic feeding operations. It can be linked with agitators, mixers, crushing equipment, etc. to improve overall process stability and production efficiency. Because of its compact structure, stable operation, clean and hygienic characteristics.

The vacuum feeder is mainly composed of vacuum pump (or vacuum generator), vacuum hopper, filter, back-blowing cleaning system, pneumatic discharge door, material level sensor, stainless steel suction gun, conveying pipeline and other parts. Among them, the filter is one of the key components of the equipment. Common materials include polyester film, PE porous filter rod, 316L stainless steel sintered mesh, titanium metal, etc., which can efficiently separate air and materials, avoid dust leakage and protect the vacuum system. The filter surface can be automatically cleaned by back-blowing with compressed air to ensure continuous and efficient operation. According to application requirements, vacuum feeders can be divided into two working modes: intermittent and continuous. Intermittent is suitable for equipment with periodic feeding, while continuous is suitable for continuous process production lines with

high requirements for material supply stability. The equipment conveying capacity can generally range from a few kilograms to several tons per hour, depending on the material characteristics, conveying distance, pipe diameter and vacuum pump power.

Vacuum feeders have many significant advantages. First, it is a closed conveying, which effectively prevents dust leakage, complies with industry standards such as GMP and FDA, and is suitable for sterile or clean environments; second, it has a high degree of automation and can be connected to the central control system to realize intelligent feeding; third, it occupies a small space and is suitable for factory layout with limited space; at the same time, it is easy to maintain and clean, and the filter components can be quickly disassembled and replaced. In addition, for materials that are easy to absorb moisture, explosive, and highly toxic, vacuum conveying is safer and more reliable than traditional mechanical conveying methods such as spirals and belts.

A vacuum feeder is an efficient device that uses vacuum negative pressure to achieve closed conveying of materials. It is mainly composed of an oil-free and water-free vacuum pump, a vacuum hopper, a high-efficiency filtration system (polyester film, PE, 316L stainless steel or titanium alloy filter element can be selected), a backflush cleaning device, a pneumatically controlled discharge valve, an automatic material level sensor, a stainless steel suction port, and a conveying hose. During operation, the vacuum pump generates a stable negative pressure airflow, sucks the material through the suction port and forms a gas-solid mixed flow along the conveying pipe, and finally enters the hopper. The filter device can effectively separate air and materials to ensure that the system is clean and dust-free. When the hopper reaches the set capacity, the system automatically stops suction and opens the discharge valve to accurately deliver the material to the downstream equipment to achieve a fully automatic continuous feeding process.

| (With vacuum pump or Roots Fan) | (With vacuum generator) | ||||||

|---|---|---|---|---|---|---|---|

| Model |

Capacity (T/h) |

Power (Kw) |

Air Consumption (L/min) |

Model |

Capacity (T/h) |

Air Pressure | Air Consumption (L/min) |

| STZK-X1 | 0.4 | 1.5 | 10 | SMSQ-F1 | 0.4 | 0.6~0.8MPa | 180-200 |

| STZK-X2 | 0.6 | 2.2 | 20 | SMSQ-F2 | 0.6 | 0.6~0.8MPa | 360-400 |

| STZK-X3 | 1.2 | 3 | 50 | SMSQ-F3 | 1.2 | 0.6~0.8MPa | 720-800 |

| STZK-X4 | 2 | 4 | 100 | SMSQ-F4 | 2 | 0.6~0.8MPa | 1450-1800 |

| STZK-X5 | 3 | 4 | 150 | SMSQ-F5 | 4 | 0.6~0.8MPa | 1800-2520 |

| STZK-X6 | 4 | 5.5 | 200 | ||||

| STZK-X7 | 6 | 7.5 | 300 | ||||

The vacuum feeder is suitable for many different types of materials, especially for conveying powdered, granular, and small batches of liquid or mixed materials. The following is a classification of common applicable material types

Powdered materials

One of the most typical application scenarios of the vacuum feeder is the closed conveying of powdered materials. Its powerful negative pressure suction and high-efficiency filtration system can handle a variety of fine and ultra-fine powders such as milk powder, flour, starch, cocoa powder, pharmaceutical powder, calcium carbonate, zinc oxide, etc. These materials are usually prone to dust, and traditional conveying methods are prone to dust flying and pollution, while vacuum conveying can achieve fully enclosed dust-free operation, especially suitable for pharmaceutical, food, chemical and other industries with extremely high cleanliness requirements. In addition, some powders are hygroscopic or electrostatic. The vacuum feeder can also be equipped with anti-static hoses, stainless steel 316L bodies and automatic back-blowing devices to effectively prevent blockage and material adhesion, ensuring a smooth and reliable conveying process.

Granular materials

Granular materials have good fluidity, and the vacuum feeder performs well in conveying plastic granules, coffee beans, desiccant granules, pills, grains, PET granules, etc. The equipment can adjust the suction and filtration structure according to the size, density and shape of the particles to ensure efficient conveying without destroying the material structure. For some fragile materials (such as tablets and granules), buffer devices or low-speed suction control can also be configured to avoid collision or crushing during conveying. Granular material conveying has high requirements for production line continuity and automation. Vacuum feeders are often used in conjunction with packaging machines, mixers, injection molding machines and other equipment to ensure stable feeding and efficient operation.

Poor fluidity or lightweight materials

For materials with poor fluidity or light specific gravity, such as silica, magnesium carbonate, foam particles, EPP/EPS lightweight filler materials or nano-powders, vacuum feeders are also capable, but structural optimization and parameter adjustment are required. Such materials may cause blockage, return or insufficient suction due to small particle size, low density, easy suspension, etc., so they are usually equipped with high-efficiency backwash cleaning systems, large-area filters or anti-blocking devices to ensure long-term and stable operation of the system. Some models also use multi-stage filtration or replaceable filter elements to meet the high-density separation requirements of extremely fine dust. For the high-standard transportation of such materials, vacuum feeders provide a safe, clean and quantitatively precise solution, which is the preferred way to replace traditional screw conveying or manual feeding.

Address:China,Yanjin county forest park gate to the west 1000 meters north road.