The Vibratory Screening Machine uses vibration to screen, remove impurities, and dewater solid particles. Suitable for a variety of materials, including powders, granules, and slurries, this machine offers a wide screening range, from 20 mesh to over 500 mesh. Processing capacity varies depending on the model and material characteristics, ranging from a few kilograms to tens of tons per hour. Depending on the material's characteristics, the particle size range ranges from a few millimeters to 500-mesh fine powder. Moisture content is generally required to be less than 5% during dry screening, while higher levels can be achieved during wet screening. For highly abrasive materials, equipment made of wear-resistant steel or ceramic coatings should be used. For highly viscous materials, a powerful cleaning system such as ultrasonic screening is required to prevent clogging. The Vibratory Screening Machine is used in a variety of processes, including impurity removal, particle grading, multi-layer fine grading, dewatering and desludging, and powder dust removal.

The Vibratory Screening Machine offers high screening efficiency and can quickly screen materials of varying particle sizes. The ratio of oversize to undersize remains stable, ensuring accurate grading. Secondly, the equipment operates stably, with consistent amplitude and low noise, ensuring long-term, efficient operation. In terms of durability, different models can be constructed of either carbon steel or stainless steel. Choosing the appropriate material for different material characteristics significantly extends the life of consumable parts. Sealing is another key feature. The equipment typically features a fully enclosed structure, effectively preventing dust and leakage, meeting GMP standards for industries such as food and pharmaceuticals. Furthermore, the screen is easily replaced and cleaned. Some models are equipped with a cleaning ball or ultrasonic cleaning system to effectively prevent screen clogging, ensuring excellent screening performance even when processing highly viscous or ultrafine powders.

In the mining and quarrying industries, vibratory screening machines are used to grade and dewater ore, coal, and sand and gravel. In the metallurgical and metal industries, they are used to screen metal powders and recover metal debris from coolants. The chemical industry relies on them to screen plastic granules, resins, pigments, and various raw materials. In the food industry, vibrating screens are essential for screening and removing impurities from sugar, salt, flour, starch, yeast, and juice, requiring stainless steel for hygienic operation. The pharmaceutical industry, with its stringent requirements for screening accuracy and hygiene, uses vibrating screens to rigorously grade APIs, traditional Chinese medicine powders, and tablet granules to ensure drug purity. Furthermore, vibratory screening machines play an indispensable role in building materials, fertilizers, ceramics, papermaking, wastewater treatment, and waste recycling.

Vibratory screening machines are available in various models based on their vibration mode and structural type. Common types include linear and circular vibrating screens. Linear vibrating screens are primarily driven by dual vibrating motors, causing the material to move linearly across the screen surface. They are suitable for screening large particles or larger throughputs. Circular vibrating screens, on the other hand, utilize a single vibrating source, causing the material to move in a circular motion across the screen surface. They are suitable for screening medium- and fine-grained materials. Ultrasonic vibrating screens integrate an ultrasonic generator into a traditional vibrating screen. This system transmits high-frequency, low-amplitude ultrasonic vibrations to the screen mesh, effectively eliminating clogging issues with highly adsorbent, highly static, and fine (500 mesh and above) materials. This ensures extremely high screening efficiency and precision.

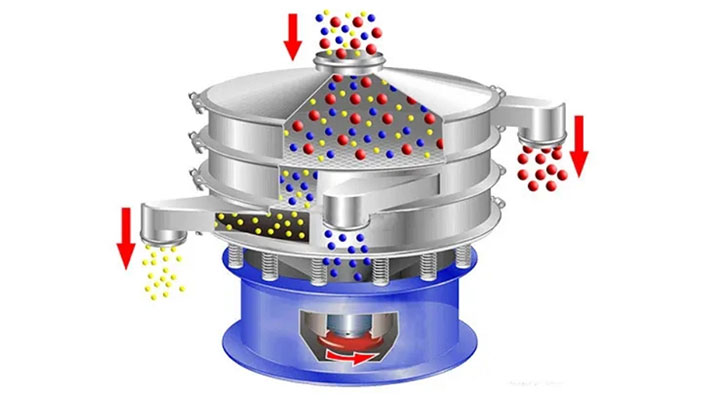

The Vibratory Screening Machine allows for the selection of screening layers based on specific needs. Single-layer screens are used for impurity removal or single-level classification. Multi-layer screens typically have 2-5 layers, equipped with screens of varying mesh sizes, to simultaneously separate products of various particle sizes. Three main types of screen mesh are commonly used for vibrating screens: Wire mesh is durable and suitable for general particulates; polyurethane mesh is wear-resistant and flexible, suitable for wet or high-impact materials; and nylon and stainless steel meshes offer high precision and are often used for fine powder processing, meeting the fine and clean requirements of industries such as food and pharmaceuticals.

The Vibratory Screening Machine utilizes a vibrating motor as an excitation source. The high-speed rotation of the motor generates a vibrating force, causing the material to be thrown across the screen surface while simultaneously moving forward in a linear or circular motion. During the process, the material gradually disperses and passes through the sieve holes, with materials of different particle sizes falling into different outlets, achieving classification. For ultrafine powders, ultrasonic vibration technology can also be used to transmit high-frequency vibration signals to the sieve surface, generating micro-vibrations that effectively prevent material adhesion and clogging, thereby improving screening efficiency.

The Vibratory Screening Machine is an efficient, stable, and highly adaptable material screening equipment that can meet a variety of production needs, including impurity removal, particle classification, dehydration and desludging, and powder dust removal. Its high screening efficiency, excellent operational stability, durability, and GMP-compliant sealing design have made it widely used in industries such as food, pharmaceuticals, chemicals, metallurgy, and building materials. By choosing the right type—linear, circular, or ultrasonic vibrating screen—and the right configuration (single-deck or multi-deck), companies can improve processing capacity and production efficiency while maintaining screening accuracy.

Address:China,Yanjin county forest park gate to the west 1000 meters north road.